Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Pulp Refiner Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Pulp Refiner Operator so you can tailor your answers to impress potential employers.

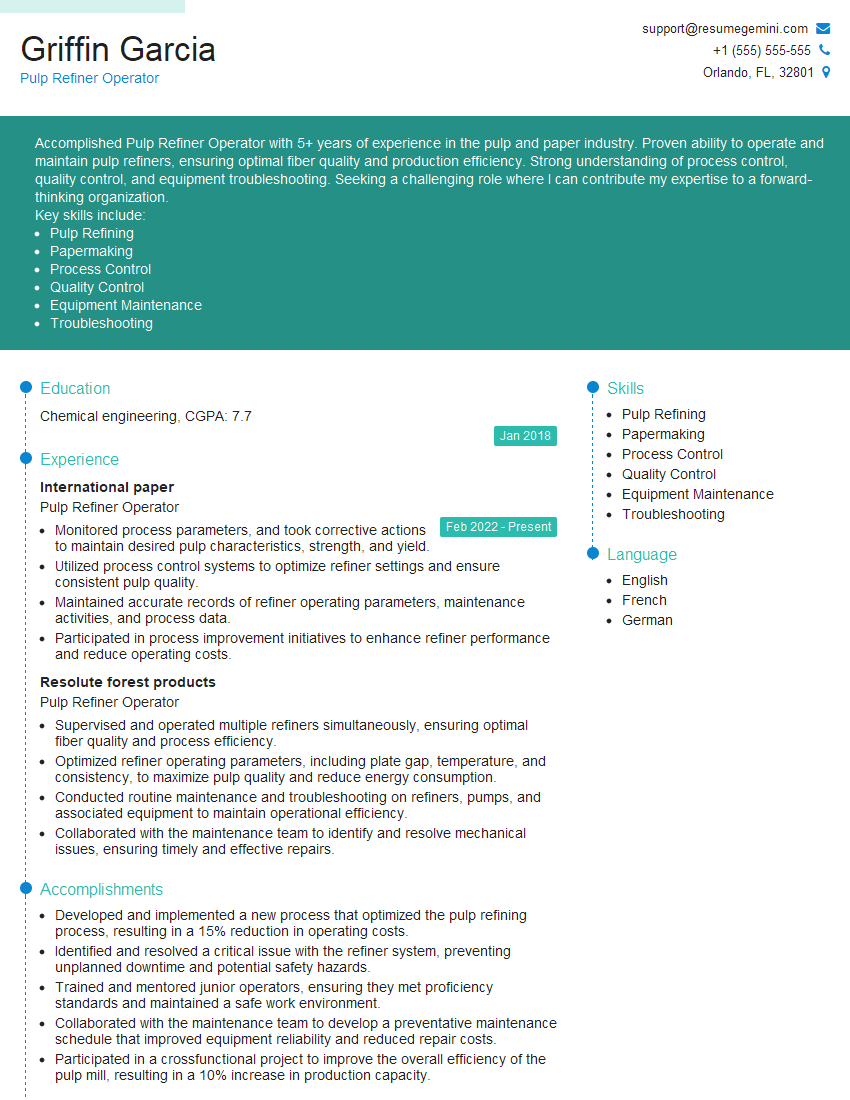

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulp Refiner Operator

1. Explain the key responsibilities of a Pulp Refiner Operator?

As a Pulp Refiner Operator, my responsibilities encompass:

- Operating pulp refiners to achieve desired fiber properties and pulp quality.

- Monitoring and adjusting process parameters such as temperature, pressure, consistency, and refining intensity.

- Conducting routine maintenance and troubleshooting equipment to ensure optimal performance.

- Maintaining a clean and safe work environment, adhering to safety regulations.

- Collaborating with other operators and production staff to optimize the pulp production process.

2. Describe the different types of pulp refiners and their applications?

Single-Disc Refiners

- Used for coarse refining, removing knots and impurities.

- Relatively low refining intensity, suitable for breaking down bulky fibers.

Double-Disc Refiners

- Higher refining intensity than single-disc refiners.

- Can be used for both coarse and fine refining, providing greater flexibility.

Conical Refiners

- Continuous refining process, allowing for precise control of fiber properties.

- Suitable for fine refining, producing high-quality pulp for specific applications.

3. How do you optimize the refining process to achieve desired pulp properties?

Optimizing the refining process involves carefully managing various parameters:

- Stock consistency: Consistency affects refining intensity, with higher consistency resulting in stronger refining action.

- Plate gap: Adjusting the distance between the refiner plates influences fiber cutting and the degree of refining.

- Power input: Power consumption is directly proportional to refining intensity, allowing for precise control.

- Temperature: Elevated temperatures soften the fibers and improve refining efficiency, while excessive heat can damage the pulp.

- Chemical additives: Chemicals can influence fiber properties and enhance refining results.

4. How do you troubleshoot common problems encountered in pulp refiners?

Troubleshooting pulp refiners requires a systematic approach:

- Vibration or noise: Indicates unbalanced rotors, worn bearings, or improper plate alignment.

- Reduced refining capacity: Can be caused by plate wear, plugged screens, or insufficient power.

- Poor pulp quality: May be due to incorrect refining settings, insufficient stock preparation, or contamination.

- Overheating: Occurs when the refiner is overloaded, plates are misaligned, or cooling systems fail.

- Excessive power consumption: Can indicate worn plates, high stock consistency, or mechanical issues.

5. Describe the safety precautions that must be followed when operating pulp refiners?

Safety is paramount when operating pulp refiners:

- Wear appropriate PPE: Hard hats, safety glasses, gloves, and earplugs.

- Maintain a clean work area: Remove debris and prevent tripping hazards.

- Lock out and tag out: Isolate equipment before performing maintenance.

- Follow proper startup and shutdown procedures: Gradually increase and decrease power to prevent damage.

- Be aware of rotating equipment: Keep a safe distance from moving parts.

6. How do you maintain pulp refiners to ensure optimal performance?

Regular maintenance is crucial for maintaining pulp refiner efficiency:

- Inspect plates: Check for wear, corrosion, and cracks.

- Clean screens: Remove accumulated debris to prevent clogging.

- Lubricate bearings: Ensure smooth operation and reduce friction.

- Inspect seals: Replace worn seals to prevent leaks.

- Perform vibration analysis: Monitor vibration levels to detect potential imbalances or mechanical issues.

7. How do you manage the production schedule and ensure timely delivery of refined pulp?

Effectively managing the production schedule is essential:

- Communicate with upstream and downstream processes: Coordinate with other departments to ensure smooth production flow.

- Monitor equipment availability: Ensure refiners are operational and ready for production.

- Prioritize orders: Determine the most critical orders and allocate resources accordingly.

- Track progress: Monitor the refining process and make adjustments as needed to meet deadlines.

- Plan for contingencies: Have backup plans in place to address unexpected events or equipment breakdowns.

8. How do you handle quality control and ensure the consistency of refined pulp?

Quality control is crucial for producing consistent pulp:

- Establish quality standards: Define the desired pulp properties and set acceptable tolerances.

- Perform regular testing: Sample and test pulp to verify compliance with standards.

- Monitor process parameters: Track and adjust process variables to maintain consistency.

- Identify and correct deviations: Promptly address any deviations from quality standards to prevent defects.

- Document and maintain records: Keep accurate records of quality control activities and results.

9. Explain the role of process automation in pulp refining and its benefits?

Automation plays a significant role in pulp refining:

- Improved efficiency: Automated systems optimize process parameters, reducing manual adjustments and increasing productivity.

- Increased consistency: Automation ensures consistent refining conditions, leading to more uniform pulp properties.

- Reduced waste: By precisely controlling process variables, automation minimizes off-spec production and reduces waste.

- Enhanced safety: Automation eliminates manual intervention, reducing the risk of accidents or injuries.

- Data collection and analysis: Automated systems collect and analyze data, providing valuable insights for process optimization.

10. Describe the latest trends and advancements in pulp refining technology?

Pulp refining technology is constantly evolving:

- High-consistency refining: Refining pulp at higher consistency levels improves energy efficiency and fiber strength.

- Advanced plate designs: Optimized plate designs enhance refining efficiency and fiber quality.

- Closed-loop control systems: Automated systems continuously monitor and adjust process parameters based on real-time data.

- Integration with other processes: Refiners are increasingly integrated with other pulp production processes for improved efficiency and quality.

- Sustainability initiatives: Focus on reducing energy consumption, water usage, and environmental impact.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulp Refiner Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulp Refiner Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pulp Refiner Operators are responsible for the safe and efficient operation of pulp refiners, which are used to reduce the size of wood fibers in the production of paper. They must ensure that the pulp is of the correct consistency and that the refiner is operating at the appropriate speed and temperature. Pulp Refiner Operators must also be able to identify and troubleshoot any problems that may occur during operation.

1. Operate and monitor pulp refiners

Pulp Refiner Operators are responsible for operating and monitoring pulp refiners, which are used to break down wood fibers into smaller pieces. They must ensure that the refiners are operating at the correct speed and temperature, and that the pulp is of the correct consistency.

- Operate pulp refiners to break down wood fibers into smaller pieces

- Monitor refiner speed and temperature to ensure optimal performance

- Adjust refiner settings to achieve desired pulp consistency

2. Maintain and troubleshoot pulp refiners

Pulp Refiner Operators are responsible for maintaining and troubleshooting pulp refiners. They must be able to identify and fix any problems that may occur during operation. They must also keep the refiners clean and well-lubricated.

- Identify and fix problems that occur during refiner operation

- Keep refiners clean and well-lubricated

- Perform regular maintenance checks to prevent breakdowns

3. Follow safety procedures

Pulp Refiner Operators must follow all safety procedures when operating and maintaining pulp refiners. They must wear appropriate personal protective equipment (PPE) and follow all lockout/tagout procedures.

- Wear appropriate PPE when operating and maintaining pulp refiners

- Follow all lockout/tagout procedures

- Be aware of potential hazards and take steps to avoid accidents

4. Work as part of a team

Pulp Refiner Operators often work as part of a team to ensure the smooth operation of the paper mill. They must be able to communicate effectively with other team members and follow instructions from supervisors.

- Communicate effectively with other team members

- Follow instructions from supervisors

- Contribute to the overall success of the paper mill

Interview Tips

Preparing for an interview for a Pulp Refiner Operator position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also help you to answer questions about the position and your qualifications.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work for the company

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Write down your answers to common interview questions

- Practice saying your answers out loud

- Get feedback from a friend or family member

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you take the interview seriously.

- Wear a suit or business casual attire

- Arrive on time for your interview

- Be polite and respectful to the interviewer

4. Be yourself and be enthusiastic

The most important thing is to be yourself and to be enthusiastic about the position. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. If you are genuinely interested in the position, your enthusiasm will come through in your interview.

- Be honest and authentic in your answers

- Show your enthusiasm for the position

- Be confident in your abilities

Next Step:

Now that you’re armed with the knowledge of Pulp Refiner Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pulp Refiner Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini