Are you gearing up for an interview for a Pulpwood Buyer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pulpwood Buyer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

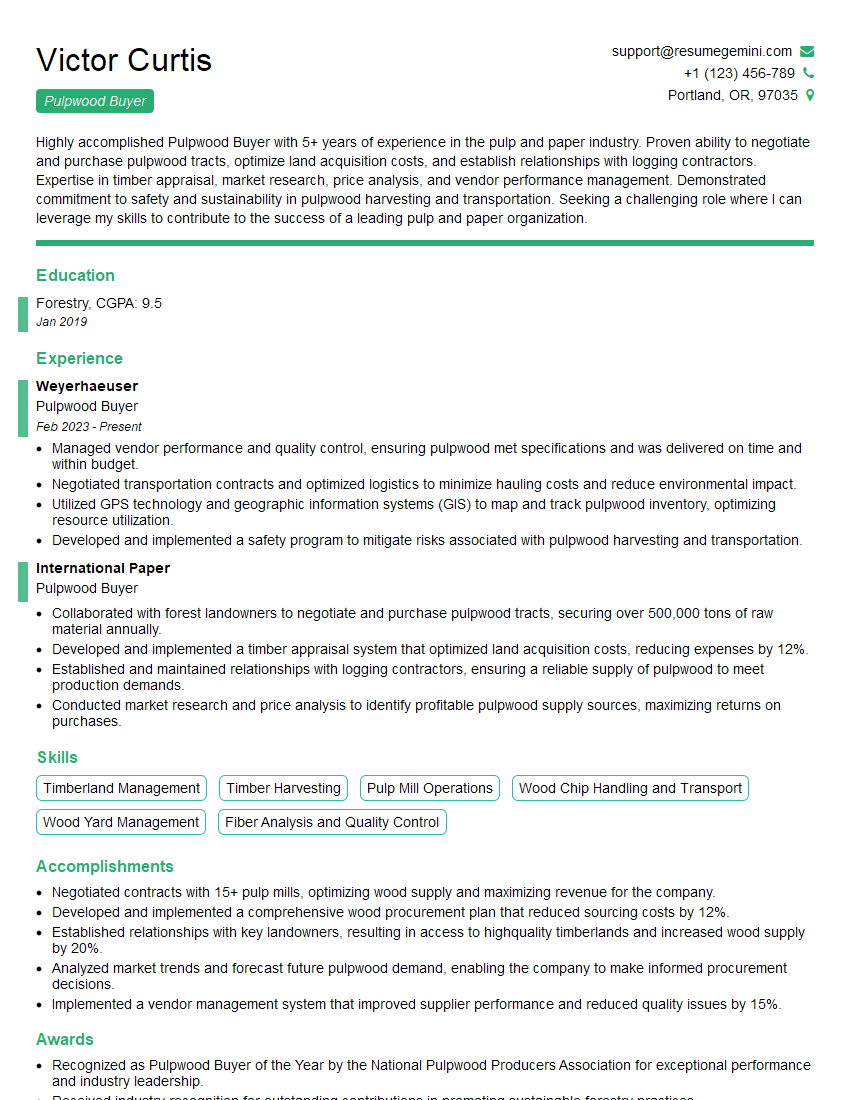

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulpwood Buyer

1. How do you determine the quality of pulpwood?

To determine the quality of pulpwood, I consider the following factors:

- Species: Different tree species have different fiber characteristics that affect pulp quality.

- Size and shape: Uniform logs with minimal knots and defects produce higher-quality pulp.

- Moisture content: Pulpwood with excessive moisture can reduce pulp yield and increase energy consumption.

- Bark content: Excessive bark can contaminate the pulp and reduce its strength.

- Storage conditions: Improper storage can lead to deterioration and reduce pulp quality.

2. Describe the process of sourcing pulpwood from suppliers.

Establishing relationships

- Identifying potential suppliers through industry contacts, trade shows, and online platforms.

- Building strong relationships with suppliers to ensure reliable supply and competitive pricing.

Negotiating contracts

- Negotiating terms that ensure quality specifications, delivery schedules, and payment conditions meet company needs.

- Understanding industry standards and market trends to secure favorable contracts.

Managing logistics

- Coordinating transportation and scheduling deliveries to align with mill production requirements.

- Optimizing logistics to minimize costs and improve efficiency.

3. How do you manage inventory levels to ensure a consistent supply of pulpwood to the mill?

To manage inventory levels effectively, I:

- Monitor inventory levels regularly using inventory management systems.

- Forecast demand based on production schedules and historical data.

- Place orders with suppliers in advance to meet demand while avoiding overstocking.

- Implement inventory control measures, such as FIFO and LIFO, to prevent spoilage and ensure quality.

- Collaborate with suppliers to adjust delivery schedules as needed to optimize inventory levels.

4. Explain the grading system used to assess pulpwood quality.

The grading system for pulpwood is designed to evaluate the quality of logs based on various criteria:

- Species: Different tree species are graded separately due to their varying fiber characteristics.

- Size and shape: Logs are graded based on diameter, length, and the presence of knots or other defects.

- Moisture content: Logs are graded based on their moisture content, which affects pulp yield and energy consumption.

- Bark content: Excessive bark can contaminate the pulp, so logs are graded based on bark thickness and coverage.

- Storage conditions: Logs that have been stored improperly may have deteriorated, so they are graded based on their condition.

Grading process

- Logs are inspected visually.

- Measurements are taken to determine size and volume.

- Moisture content and bark thickness are tested.

- Logs are graded according to established standards.

5. Discuss the challenges you have encountered in pulpwood procurement and how you overcame them.

One challenge I faced was a shortage of supply due to a natural disaster that affected a major supplier.

How I overcame it

- Identified alternative suppliers in different regions.

- Negotiated flexible delivery schedules to accommodate the disruption.

- Implemented stricter quality control measures to ensure the quality of pulpwood sourced from new suppliers.

Another challenge was optimizing inventory levels to minimize costs while ensuring a consistent supply.

How I overcame it

- Improved demand forecasting accuracy using statistical models.

- Implemented a more efficient inventory management system.

- Collaborated with suppliers to adjust delivery schedules as needed.

6. How do you stay updated on industry trends and advancements in pulpwood procurement?

- Attending industry conferences and workshops.

- Reading trade publications and industry reports.

- Networking with other pulpwood buyers and professionals.

- Exploring new technologies and solutions through research and development.

7. Describe your experience with developing and implementing sustainable pulpwood procurement practices.

In my previous role, I developed a sustainable pulpwood procurement program that aimed to:

- Promote responsible forestry practices.

- Reduce environmental impact.

- Support local communities.

Key initiatives

- Established partnerships with certified forest landowners.

- Implemented policies to minimize soil erosion and protect water quality.

- Provided training to suppliers on sustainable harvesting techniques.

- Supported community programs that promoted reforestation and biodiversity.

8. How do you prioritize and manage multiple tasks in a fast-paced environment?

- Using a task management system to track responsibilities and deadlines.

- Breaking down large tasks into smaller, manageable steps.

- Delegating tasks to team members when appropriate.

- Prioritizing tasks based on urgency and importance.

- Seeking support from colleagues and supervisors when needed.

9. Explain how you negotiate effectively with suppliers.

- Preparing thoroughly by researching the market and understanding the supplier’s needs.

- Establishing a positive and respectful relationship with the supplier.

- Clearly communicating my objectives and priorities.

- Being willing to compromise and find mutually acceptable solutions.

- Documenting agreements clearly and following up to ensure compliance.

10. How do you evaluate the performance of suppliers and identify areas for improvement?

- Establishing clear performance metrics, such as quality, delivery time, and cost.

- Regularly monitoring supplier performance using data and feedback.

- Providing feedback to suppliers on areas where they can improve.

- Working with suppliers to develop improvement plans and provide support.

- Rewarding suppliers for exceptional performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulpwood Buyer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulpwood Buyer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pulpwood Buyers play a critical role in the supply chain of paper and wood products industries. Their key responsibilities include:

1. Sourcing and Procurement

Sourcing and procuring pulpwood from various suppliers, including landowners, loggers, and wood exporters.

- Negotiating and securing contracts with suppliers to ensure a reliable and cost-effective supply of pulpwood.

- Developing and maintaining relationships with suppliers to foster long-term partnerships.

2. Quality Control and Inspection

Inspecting and grading pulpwood to ensure it meets quality standards and specifications.

- Establishing and implementing quality control procedures to maintain the consistency and grade of pulpwood.

- Conducting regular inspections of pulpwood deliveries to verify compliance with agreed-upon standards.

3. Market Analysis and Forecasting

Monitoring market trends, including pulpwood supply and demand, to forecast future market conditions.

- Gathering and analyzing data on pulpwood supply, demand, and prices to make informed purchasing decisions.

- Developing supply chain management strategies to mitigate risks and optimize pulpwood procurement.

4. Inventory Management

Maintaining optimal inventory levels of pulpwood to meet production needs while minimizing storage costs.

- Tracking inventory levels and forecasting future demand to ensure a smooth flow of pulpwood into the mill.

- Developing and implementing inventory management systems to optimize storage and handling practices.

Interview Tips

Preparation is key to acing any job interview. Here are some specific tips for a Pulpwood Buyer interview:

1. Research the Company and Industry

Research the paper or wood products company you are applying to, as well as the pulpwood industry as a whole. This will help you understand their business operations, market position, and industry trends.

- Visit the company’s website to learn about their mission, values, and products.

- Read industry publications and news articles to stay up-to-date on market developments.

2. Highlight Relevant Experience and Skills

In your resume and interview, emphasize your experience and skills that are most relevant to the role of a Pulpwood Buyer. These may include:

- Experience in procurement, supply chain management, or forestry.

- Knowledge of pulpwood grading and quality standards.

- Strong negotiation and communication skills.

3. Prepare for Common Interview Questions

Anticipate common interview questions related to pulpwood procurement, market analysis, and inventory management. Practice answering these questions in a clear and concise manner.

- What are your strategies for sourcing and securing pulpwood supplies?

- How do you ensure the quality of pulpwood delivered to the mill?

- Describe your approach to forecasting pulpwood supply and demand.

4. Ask Thoughtful Questions

Asking insightful questions at the end of the interview demonstrates your interest in the role and the company. Prepare a few questions related to the pulpwood procurement process, company culture, or industry outlook.

- What are the company’s sustainability initiatives related to pulpwood procurement?

- How does the company handle fluctuations in pulpwood supply and demand?

- What are the opportunities for professional development and advancement within the company?

Next Step:

Now that you’re armed with the knowledge of Pulpwood Buyer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pulpwood Buyer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini