Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pulverizer Mill Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

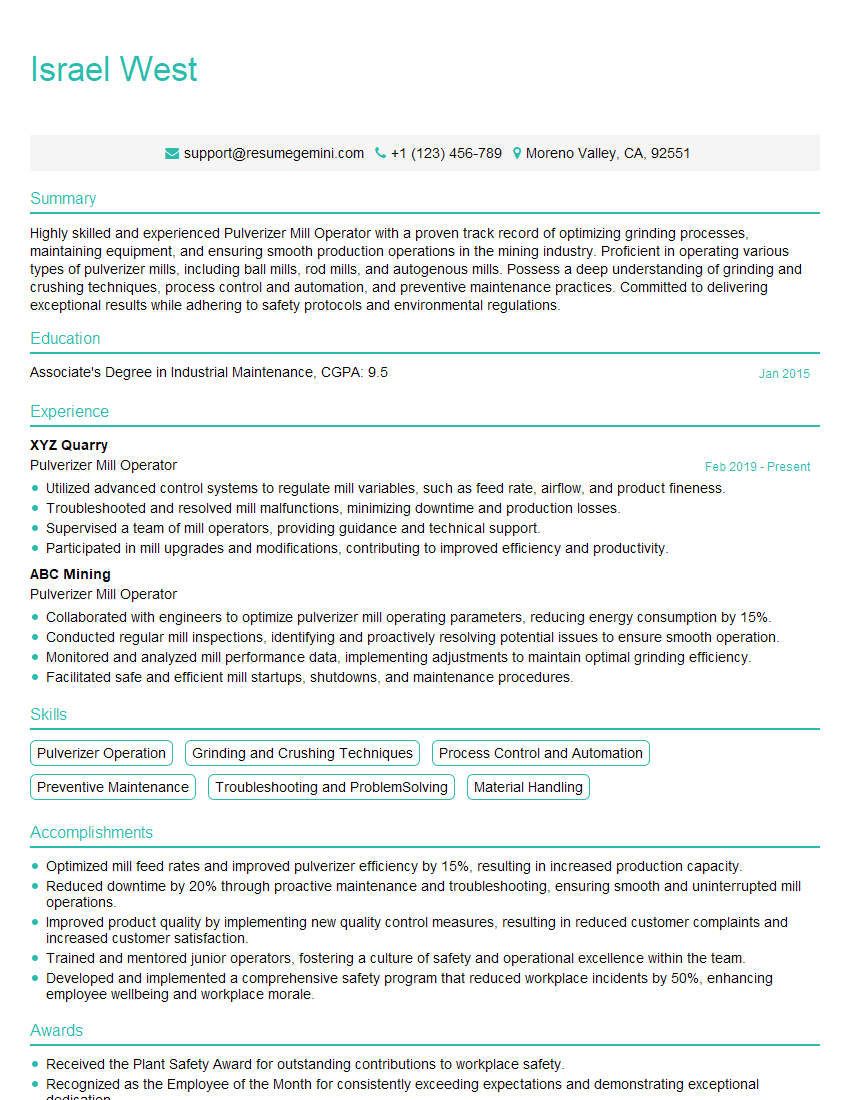

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulverizer Mill Operator

1. Explain the working principle of a pulverizer mill?

A pulverizer mill is a machine that uses impact, attrition, or cutting action to grind materials into a fine powder. The working principle of a pulverizer mill is as follows:

- The material to be pulverized is fed into the mill through a hopper.

- The material is then subjected to a combination of impact, attrition, or cutting action, depending on the type of mill.

- The pulverized material is then discharged from the mill through a screen or classifier.

2. What are the different types of pulverizer mills?

There are many different types of pulverizer mills, each with its own advantages and disadvantages. Some of the most common types include:

Impact pulverizers

- Impact pulverizers use high-speed impellers to crush the material to be pulverized.

- Impact pulverizers are relatively simple to operate and maintain.

- Impact pulverizers are not suitable for materials that are sensitive to heat or shear.

Attrition pulverizers

- Attrition pulverizers use a combination of grinding wheels and screens to grind the material to be pulverized.

- Attrition pulverizers are capable of producing very fine powders.

- Attrition pulverizers are more expensive to operate and maintain than impact pulverizers.

Cutting pulverizers

- Cutting pulverizers use a combination of knives and screens to cut the material to be pulverized.

- Cutting pulverizers are capable of producing very fine powders.

- Cutting pulverizers are more expensive to operate and maintain than impact or attrition pulverizers.

3. What are the factors to consider when selecting a pulverizer mill?

When selecting a pulverizer mill, it is important to consider the following factors:

- The type of material to be pulverized

- The desired particle size

- The capacity required

- The operating costs

- The maintenance costs

4. What are the common problems encountered with pulverizer mills?

Some of the common problems encountered with pulverizer mills include:

- Overheating

- Vibration

- Blockage

- Wear and tear

5. How do you troubleshoot a pulverizer mill?

To troubleshoot a pulverizer mill, it is important to first identify the symptoms of the problem. Once the symptoms have been identified, the following steps can be taken to troubleshoot the problem:

- Check the power supply

- Check the lubrication

- Check the screens or classifiers

- Check the impellers or grinding wheels

- Check the knives

6. What are the safety precautions that should be taken when operating a pulverizer mill?

The following safety precautions should be taken when operating a pulverizer mill:

- Wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, earplugs, and gloves.

- Do not operate the mill if it is not properly guarded.

- Do not touch the mill while it is in operation.

- Keep the mill area clean and free of debris.

- Follow all manufacturer’s instructions for safe operation.

7. What is the importance of preventive maintenance for a pulverizer mill?

Preventive maintenance is important for a pulverizer mill for the following reasons:

- It helps to prevent breakdowns

- It helps to extend the life of the mill

- It helps to reduce operating costs

- It helps to ensure the safety of the operators

8. What are the common maintenance tasks that should be performed on a pulverizer mill?

The following common maintenance tasks should be performed on a pulverizer mill:

- Lubricate the bearings

- Inspect the screens or classifiers

- Inspect the impellers or grinding wheels

- Inspect the knives

- Check the power supply

- Clean the mill

9. What are the signs that a pulverizer mill needs to be repaired?

The following signs indicate that a pulverizer mill needs to be repaired:

- Overheating

- Vibration

- Blockage

- Wear and tear

- Noise

10. How do you calibrate a pulverizer mill?

To calibrate a pulverizer mill, the following steps can be taken:

- Set the mill to the desired particle size

- Grind a sample of the material to be pulverized

- Measure the particle size of the ground sample

- Adjust the mill settings as needed to achieve the desired particle size

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulverizer Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulverizer Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pulverizer Mill Operators are responsible for the safe and efficient operation of pulverizer mills, which are used to grind raw materials into fine powders. They must have a thorough understanding of the principles of pulverization and the operation of pulverizer mills. Key job responsibilities include:

1. Operate and maintain pulverizer mills

Pulverizer Mill Operators are responsible for the safe and efficient operation of pulverizer mills. They must ensure that the mills are properly maintained and calibrated, and that they are operated in accordance with established procedures. They must also be able to troubleshoot and repair minor problems.

2. Monitor product quality

Pulverizer Mill Operators are responsible for monitoring the quality of the pulverized product. They must ensure that the product meets the required specifications for particle size and other quality parameters. They must also be able to identify and correct any problems with the product quality.

3. Maintain a clean and safe work environment

Pulverizer Mill Operators are responsible for maintaining a clean and safe work environment. They must ensure that the work area is free of hazards, and that all equipment is properly guarded. They must also comply with all applicable safety regulations.

4. Follow established procedures

Pulverizer Mill Operators must follow all established procedures for the operation and maintenance of pulverizer mills. They must also comply with all applicable safety regulations. Failure to follow established procedures can result in accidents, injuries, or damage to equipment.

Interview Tips

Preparing for a Pulverizer Mill Operator interview can be daunting, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the company and the position

Take the time to research the company you are applying to and the Pulverizer Mill Operator position. This will help you understand the company’s culture, values, and goals. It will also help you tailor your answers to the interviewer’s questions.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked. Practice answering these questions in advance so that you can deliver clear and concise responses. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with pulverizer mills?

- How do you maintain a clean and safe work environment?

3. Be prepared to talk about your experience

The interviewer will want to know about your experience as a Pulverizer Mill Operator. Be prepared to talk about your responsibilities, your accomplishments, and any challenges you have faced. Use specific examples to illustrate your skills and experience.

4. Be enthusiastic and professional

Make sure to be enthusiastic and professional during the interview. The interviewer will be looking for someone who is passionate about the position and who is a good fit for the company. Be respectful of the interviewer’s time and answer their questions honestly and thoughtfully.

5. Follow up after the interview

After the interview, it is important to follow up with the interviewer. Send a thank-you note and reiterate your interest in the position. You can also use the follow-up letter to address any questions or concerns that the interviewer may have had.

Next Step:

Now that you’re armed with the knowledge of Pulverizer Mill Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pulverizer Mill Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini