Are you gearing up for a career in Pulverizer Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pulverizer Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

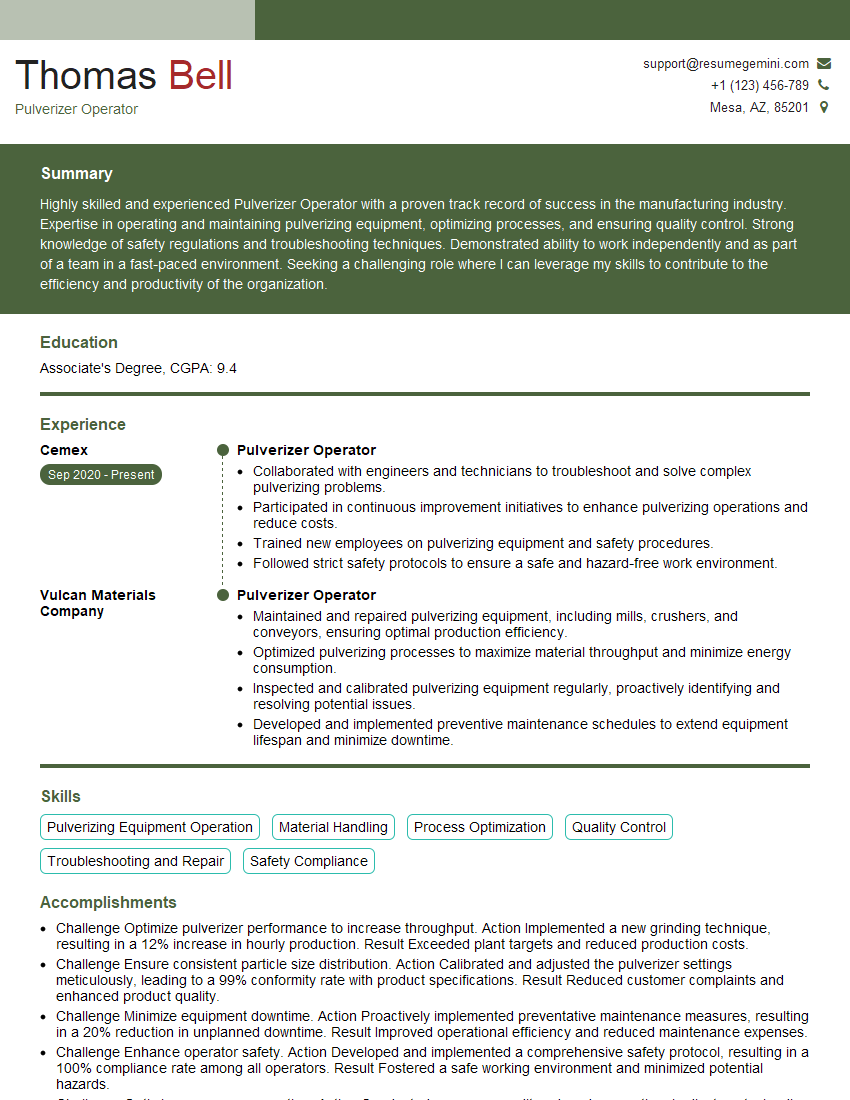

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulverizer Operator

1. Explain the different types of pulverizers?

Pulverizers are devices used to grind or crush materials into a fine powder. There are different types of pulverizers, each with its own unique design and purpose:

- Ball mill: Uses rotating balls to grind materials by impact and attrition.

- Hammer mill: Uses rotating hammers to smash and break materials.

- Impact mill: Uses high-speed impellers to smash materials against a stationary surface.

- Rod mill: Similar to a ball mill, but uses rods instead of balls.

- Attrition mill: Uses friction to grind materials between two surfaces.

2. Describe the process of pulverizing coal in a ball mill?

Coal Preparation:

- Coal is first crushed into smaller pieces.

- Crushed coal is dried to remove moisture.

Pulverization:

- Dried coal is fed into the ball mill.

- Rotating balls inside the mill impact and grind the coal into a fine powder.

- Grinding media (balls) are lifted and dropped to increase the impact on coal particles.

Classification and Separation:

- Pulverized coal is separated into different sizes using a classifier.

- Larger particles are returned to the ball mill for further grinding.

- Fine coal powder is collected and stored for use.

3. What are the key factors that affect the efficiency of a pulverizer?

- Type of material being pulverized: Hardness, size, and moisture content.

- Pulverizer design: Size and shape of the grinding chamber, type and size of grinding media.

- Operating parameters: Speed, feed rate, and temperature.

- Maintenance: Regular inspection, lubrication, and replacement of worn parts.

- Environmental conditions: Temperature, humidity, and dust levels.

4. How do you troubleshoot common problems with pulverizers?

- Reduced capacity: Check for worn grinding media, proper feed rate, and blockages.

- Coarse grind: Adjust the grinding time, speed, or feed rate.

- Overheating: Check for lubrication issues, bearing failures, or excessive friction.

- Unusual noises or vibrations: Inspect the pulverizer for loose parts, unbalanced grinding media, or misalignment.

- High energy consumption: Analyze the operating parameters, material characteristics, and pulverizer efficiency.

5. Describe the safety precautions that should be taken when operating a pulverizer?

- Wear appropriate personal protective equipment (PPE), including earplugs, safety glasses, and gloves.

- Ensure the pulverizer is properly grounded and electrically isolated before maintenance.

- Lock out and tag out the pulverizer before performing any work.

- Follow established operating procedures and never exceed the specified operating parameters.

- Be aware of potential hazards such as dust explosions, rotating parts, and high temperatures.

6. What is the role of classifiers in a pulverizing system?

- Separate pulverized material into different size fractions.

- Control the fineness of the final product.

- Return oversize particles to the pulverizer for further grinding.

- Improve the overall efficiency and productivity of the pulverizing process.

7. Explain the importance of regular maintenance for pulverizers?

- Prevent breakdowns and extend equipment life: Regular inspections and maintenance can identify and address potential issues before they become major problems.

- Maintain optimal performance: Proper maintenance ensures that the pulverizer operates efficiently and produces the desired product quality.

- Reduce energy consumption: Well-maintained pulverizers consume less energy and operate more efficiently.

- Ensure safety: Regular maintenance helps prevent accidents and injuries by keeping the pulverizer in safe operating condition.

- Improve productivity: Minimizing downtime and maximizing uptime through regular maintenance increases overall productivity.

8. Describe the different types of grinding media used in pulverizers?

- Balls: Used in ball mills, typically made of steel or ceramic.

- Rods: Used in rod mills, typically made of steel or ceramic.

- Hammers: Used in hammer mills, typically made of steel or alloy.

- Impellers: Used in impact mills, typically made of steel or alloy.

- Grinding plates: Used in attrition mills, typically made of steel or ceramic.

9. Explain the concept of closed-circuit grinding in a pulverizing system?

- Pulverized material is continuously recirculated through the pulverizer and classifier.

- Classifier separates the fine particles from the coarse particles.

- Coarse particles are returned to the pulverizer for further grinding.

- Closed-circuit grinding produces a more consistent and finer product.

10. Describe the role of automation in modern pulverizing systems?

- Process control: Automates the adjustment of operating parameters, such as feed rate and grinding speed.

- Monitoring: Continuously monitors the pulverizer’s performance and alerts operators to any issues.

- Data collection: Gathers and analyzes data on pulverizer performance and material characteristics.

- Optimization: Uses advanced algorithms to optimize the pulverizing process for efficiency and product quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulverizer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulverizer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pulverizer Operators are responsible for ensuring efficient operation of pulverizers, which grind raw materials into fine powder. Essential duties include:

1. Equipment Management

Operate and monitor pulverizers to ensure optimal performance, adjusting variables such as speed, feed rate, and particle size.

- Conduct routine maintenance and repairs to keep equipment in top condition.

- Troubleshoot and resolve operational issues to minimize downtime.

2. Material Handling

Manage raw materials, ensuring proper feeding into the pulverizer and monitoring output.

- Inspect raw materials for quality and consistency.

- Control the flow of materials through the grinding process.

3. Quality Control

Monitor the quality of finished products, adhering to established specifications and customer requirements.

- Conduct particle size analysis and other quality checks.

- Implement corrective actions to maintain product quality.

4. Safety and Compliance

Maintain a safe and compliant work environment in accordance with industrial regulations and company policies.

- Wear appropriate safety gear and follow prescribed safety protocols.

- Adhere to environmental regulations and ensure proper disposal of waste.

Interview Tips

To ace the interview for a Pulverizer Operator position, prepare thoroughly and demonstrate your skills and experience. Here are some tips:

1. Research the Company and Industry

Familiarize yourself with the company’s business, products, and industry trends. Highlight your understanding of the pulverization process and its importance.

- Review the company website, industry publications, and research the latest advancements in pulverizing technology.

- Prepare questions to ask the interviewer about the company’s pulverization operations and goals.

2. Showcase Your Technical Expertise

Emphasize your knowledge of pulverizer operation, maintenance, and troubleshooting techniques. Quantify your accomplishments with specific examples.

- Highlight your experience in adjusting process parameters to optimize pulverizer performance.

- Describe how you successfully resolved a major equipment malfunction, saving the company time and resources.

3. Demonstrate Quality Focus

Explain your commitment to quality control and your ability to maintain consistent product quality. Share examples of your attention to detail.

- Describe your experience in implementing quality control measures and maintaining product specifications.

- Provide examples of your ability to detect and correct quality deviations.

4. Emphasize Safety and Compliance

Highlight your understanding of safety regulations and your commitment to maintaining a safe work environment. Show that you are familiar with industry best practices.

- Explain how you ensure compliance with safety protocols and environmental regulations.

- Describe your experience in handling hazardous materials and waste disposal procedures.

Next Step:

Now that you’re armed with the knowledge of Pulverizer Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pulverizer Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini