Are you gearing up for a career in Pulverizing and Sifting Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pulverizing and Sifting Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

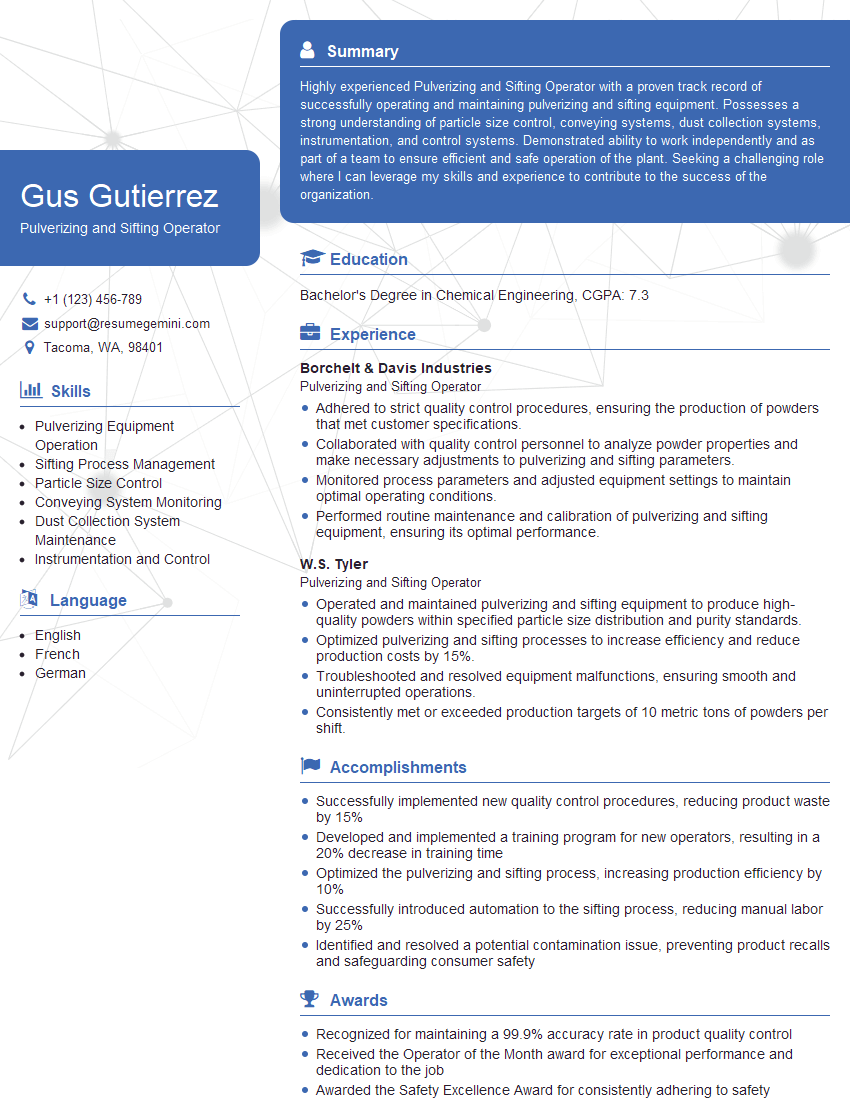

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulverizing and Sifting Operator

1. What are the different types of pulverizers and sifters used in the industry?

As a skilled Pulverizing and Sifting Operator, I am familiar with various types of pulverizers and sifters used in the industry. Pulverizers include impact mills, hammer mills, fluidized bed jet mills, and cryogenic mills, while sifters encompass vibratory sifters, rotary sifters, centrifugal sifters, and ultrasonic sifters. I possess the knowledge and experience to operate these machines efficiently and effectively.

2. How do you determine the appropriate settings for a pulverizer or sifter based on the material properties?

Material Properties Considered:

- Particle size and distribution

- Hardness and abrasiveness

- Moisture content

- Bulk density

Settings Adjustment:

- Adjust rotor speed, blade geometry, or impact force for pulverizers

- Adjust screen mesh size, vibration frequency, or amplitude for sifters

3. What are the important safety precautions to observe when operating a pulverizer or sifter?

Safety is paramount when operating pulverizers or sifters. Key precautions include:

- Wearing appropriate PPE (gloves, safety glasses, earplugs)

- Ensuring proper machine grounding and electrical connections

- Inspecting equipment regularly for any damage or wear

- Following lockout/tagout procedures during maintenance

- Being aware of potential hazards such as dust explosions or material spills

4. How do you troubleshoot common problems encountered with pulverizers or sifters?

Troubleshooting is crucial to maintain efficient operation. Common problems and solutions include:

- Clogging: Adjust feed rate, clean screens, or inspect for material buildup

- Uneven particle size: Calibrate pulverizer settings, replace worn blades or screens

- Vibration or noise: Check for loose components, imbalances, or bearing issues

- Overheating: Monitor motor temperature, inspect for blockages or lubrication problems

5. What is the role of quality control in pulverizing and sifting operations?

Quality control is essential to ensure product consistency. I conduct regular checks on:

- Particle size distribution: Using sieves or particle size analyzers

- Purity: Inspecting for contaminants or foreign materials

- Moisture content: Utilizing moisture meters or drying ovens

- Bulk density: Measuring weight and volume

6. How do you maintain and calibrate pulverizers and sifters to ensure optimal performance?

Regular maintenance and calibration are crucial. I perform the following tasks:

- Cleaning and lubrication: Remove dust, debris, and apply lubricants

- Screen replacement: Inspect and replace worn or damaged screens

- Calibration: Verify accuracy of particle size measurements using standard samples

- Record keeping: Document maintenance logs and calibration results

7. What are the environmental and health hazards associated with pulverizing and sifting operations?

I am aware of the potential hazards, which include:

- Dust and airborne particles: Use dust collectors, wear respirators

- Noise pollution: Employ soundproofing materials, earplugs

- Material spills: Implement spill containment measures

- Electrical hazards: Ensure proper grounding and lockout procedures

8. How do you ensure that the pulverized and sifted materials meet the required specifications?

I adhere to established quality standards and follow these steps:

- Monitor process parameters: Temperature, feed rate, screen size

- Conduct regular quality checks: Particle size analysis, purity testing

- Adjust settings as needed: Based on quality control results

- Document production records: Maintain traceability and ensure compliance

9. What are the different methods of feeding materials into a pulverizer or sifter?

Materials can be fed into pulverizers and sifters using various methods, such as:

- Gravity feeding: Utilizing chutes or hoppers

- Pneumatic conveying: Transporting materials using air or gas

- Mechanical conveying: Employing conveyors or augers

- Manual feeding: Adding materials by hand (limited to small-scale operations)

10. How do you handle and dispose of waste materials generated during pulverizing and sifting operations?

Proper waste management is crucial. I follow these practices:

- Dust collection: Utilizing cyclones or bag filters

- Waste disposal: Adhering to environmental regulations

- Recycling: Reusing materials whenever possible

- Minimizing waste: Optimizing process efficiency

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulverizing and Sifting Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulverizing and Sifting Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pulverizing and Sifting Operators are responsible for the smooth operation of pulverizing and sifting equipment in various industries. The key job responsibilities include:

1. Equipment Operation and Maintenance

Operate pulverizing and sifting equipment to grind and separate materials into desired particle sizes.

- Monitor equipment performance and make necessary adjustments to ensure efficient operation.

- Lubricate, clean, and maintain equipment regularly to prevent breakdowns and ensure longevity.

2. Raw Material Handling

Handle raw materials, such as ores, minerals, or chemicals, for processing.

- Load and unload materials into and from equipment using conveyors or other material handling systems.

- Inspect raw materials for quality and contamination.

3. Quality Control

Conduct quality control checks on processed materials.

- Collect samples for testing and analysis.

- Adjust equipment settings to meet product specifications.

- Maintain records of quality control data.

4. Safety and Compliance

Ensure compliance with safety regulations and standard operating procedures.

- Wear appropriate personal protective equipment (PPE).

- Follow established safety protocols during equipment operation and maintenance.

- Report any safety concerns or incidents promptly.

Interview Tips

To ace the interview for a Pulverizing and Sifting Operator position, consider the following tips:

1. Research the Industry and Company

Familiarize yourself with the industry you’re applying to and the specific company you’re interviewing with. This will help you understand the job requirements and company culture.

2. Highlight Your Experience and Skills

Emphasize your experience in operating pulverizing and sifting equipment, especially if you have worked in a similar industry.

3. Showcase Your Quality Control Knowledge

Demonstrate your understanding of quality control procedures and your ability to maintain product specifications.

4. Safety and Compliance Knowledge

Highlight your adherence to safety protocols and your knowledge of relevant regulations.

5. Team Experience

Explain your experience working in a team environment, as this is often a requirement for Pulverizing and Sifting Operators.

6. Common Interview Questions

Prepare answers to common interview questions, such as:

- Tell me about your experience in operating pulverizing and sifting equipment.

- How do you ensure the quality of processed materials?

- What safety protocols do you follow during your work?

- How do you handle situations when equipment malfunctions?

- Why are you interested in this position and our company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pulverizing and Sifting Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.