Are you gearing up for a career in Pump Erector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pump Erector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pump Erector

1. Describe the process of aligning a pump and motor?

The process of aligning a pump and motor involves the following steps:

- Mounting the motor and pump on a common baseplate

- Installing a laser alignment tool to the pump shaft

- Rotating the motor while monitoring the laser beam

- Adjusting the motor’s position until the laser beam is centered on the target on the pump shaft

- Tightening the motor’s bolts to secure it in place

2. What are the different types of pumps you have worked on?

Centrifugal Pumps

- Horizontal and vertical

- Single-stage and multi-stage

- End-suction and side-suction

Positive Displacement Pumps

- Reciprocating pumps

- Diaphragm pumps

- Rotary pumps

3. How do you troubleshoot a pump that is not operating properly?

Troubleshooting a pump that is not operating properly involves identifying the symptoms and then determining the root cause.

- Check for power to the pump

- Inspect the pump for leaks

- Listen for unusual noises or vibrations

- Check the pump’s pressure and flow rate

- Inspect the pump’s impeller and diffusers for damage

4. What are the safety precautions that need to be taken when working with pumps?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs

- Lock out and tag out the pump before performing any maintenance

- Be aware of the potential for hazards such as electrical shock, rotating machinery, and high-pressure fluids

- Follow all manufacturer’s instructions for safe operation and maintenance

5. What is the difference between a centrifugal pump and a positive displacement pump?

- Centrifugal pumps rely on rotating impellers to move fluid, while positive displacement pumps use a variety of mechanisms to create a seal between the suction and discharge ports.

- Centrifugal pumps can handle high flow rates but have limited pressure capabilities, while positive displacement pumps can generate higher pressures but have lower flow rates.

- Centrifugal pumps are typically used for applications where high flow rates are required, such as in firefighting or flood control.

- Positive displacement pumps are typically used for applications where high pressures are required, such as in hydraulic systems or chemical processing.

6. How do you calculate the efficiency of a pump?

The efficiency of a pump is calculated using the following formula:

Efficiency = (Power output / Power input) x 100%

- Power output is the rate at which the pump delivers water to the system, measured in watts or horsepower.

- Power input is the rate at which the pump consumes electricity, measured in watts or horsepower.

7. What are some common problems that can occur with pumps?

- Leaking seals

- Clogged impellers

- Faulty bearings

- Overheating

- Electrical problems

8. How do you maintain a pump to extend its lifespan?

- Regularly inspect the pump for leaks, clogs, and other problems

- Lubricate the pump’s bearings according to the manufacturer’s instructions

- Replace worn or damaged parts as needed

- Follow the manufacturer’s instructions for proper storage when the pump is not in use

9. How do you stay up-to-date on the latest developments in pump technology?

- Read trade publications

- Attend industry conferences and events

- Take online courses and training programs

- Network with other pump professionals

10. Describe a time when you had to troubleshoot a complex pump problem

I was once called to troubleshoot a centrifugal pump that had suddenly stopped working. I checked the power supply, the impeller, and the bearings, but found no obvious problems. I then used a laser alignment tool to check the alignment of the pump and motor, and found that the pump was slightly misaligned. I realigned the pump and motor, and the pump started working again.

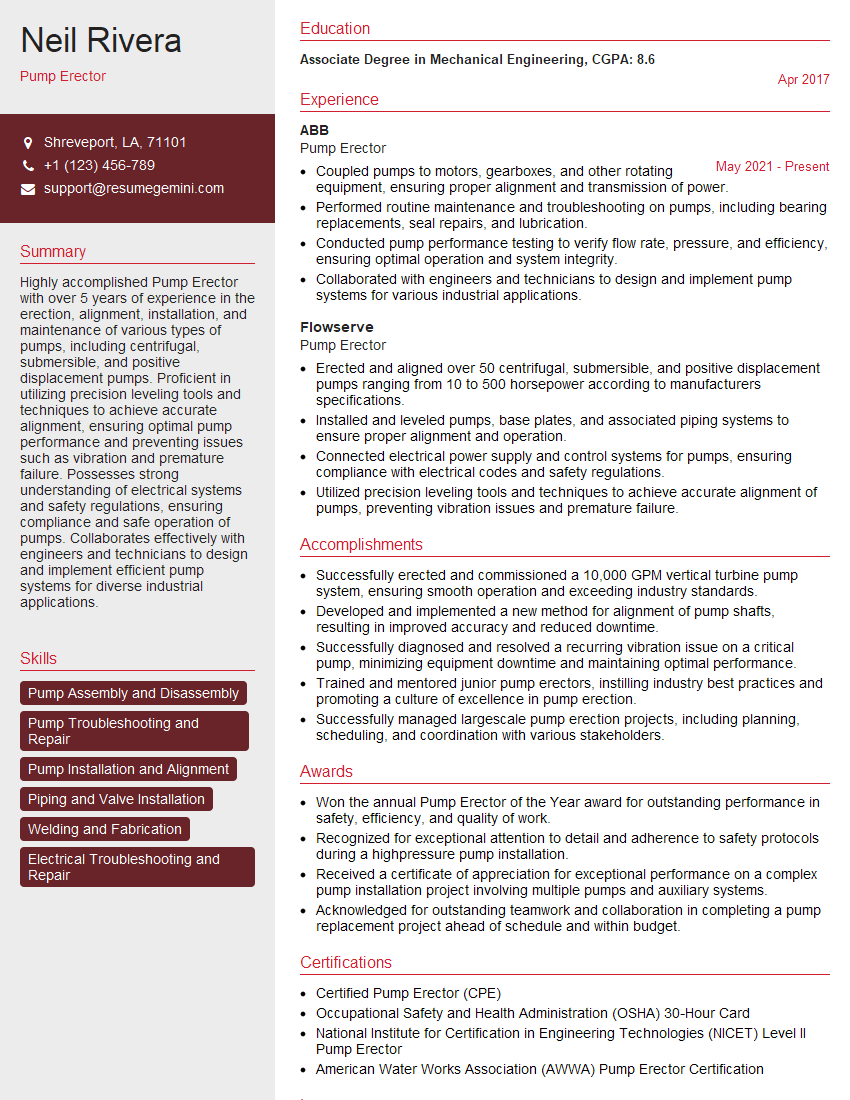

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pump Erector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pump Erector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pump Erectors are responsible for the installation, maintenance, and repair of pumps and related equipment. Their duties include:

1. Installation of Pumps

Pump Erectors install pumps by following the manufacturer’s instructions, ensuring that the pumps are level and properly aligned with the piping and other components.

2. Maintenance of Pumps

Pump Erectors perform regular maintenance on pumps to ensure their proper operation. This includes checking the pumps for leaks, vibrations, and other problems, and performing repairs as needed.

3. Repair of Pumps

Pump Erectors repair pumps when they fail. this includes replacing seals, bearings, and other components, and performing other repairs as needed.

4. Troubleshooting

Pump Erectors troubleshoot problems with pumps by identifying the cause of the problem and taking steps to correct it.

Interview Tips

To ace your interview as a Pump Erector, you need to be prepared to answer questions about your experience, skills, and knowledge. Here are some tips to help you prepare:

1. Research the Company

Before your interview, take the time to research the company you are applying to. This will help you to understand the company’s culture and values, and to tailor your answers to the specific needs of the company.

2. Practice Your Answers

Once you have researched the company and identified the specific questions that you may be asked, practice your answers. This will help you to be confident and articulate during your interview.

3. Be Enthusiastic and Professional

During your interview, be enthusiastic about the position and the company. This will show the interviewer that you are interested in the job and that you are a motivated individual.

4. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience as a Pump Erector. Be prepared to talk about your past projects and how you contributed to their success.

5. Be Prepared to Answer Technical Questions

The interviewer may also ask you technical questions about pumps and their operation. Be prepared to answer these questions in a clear and concise manner.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pump Erector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pump Erector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.