Feeling lost in a sea of interview questions? Landed that dream interview for Pump House Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pump House Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

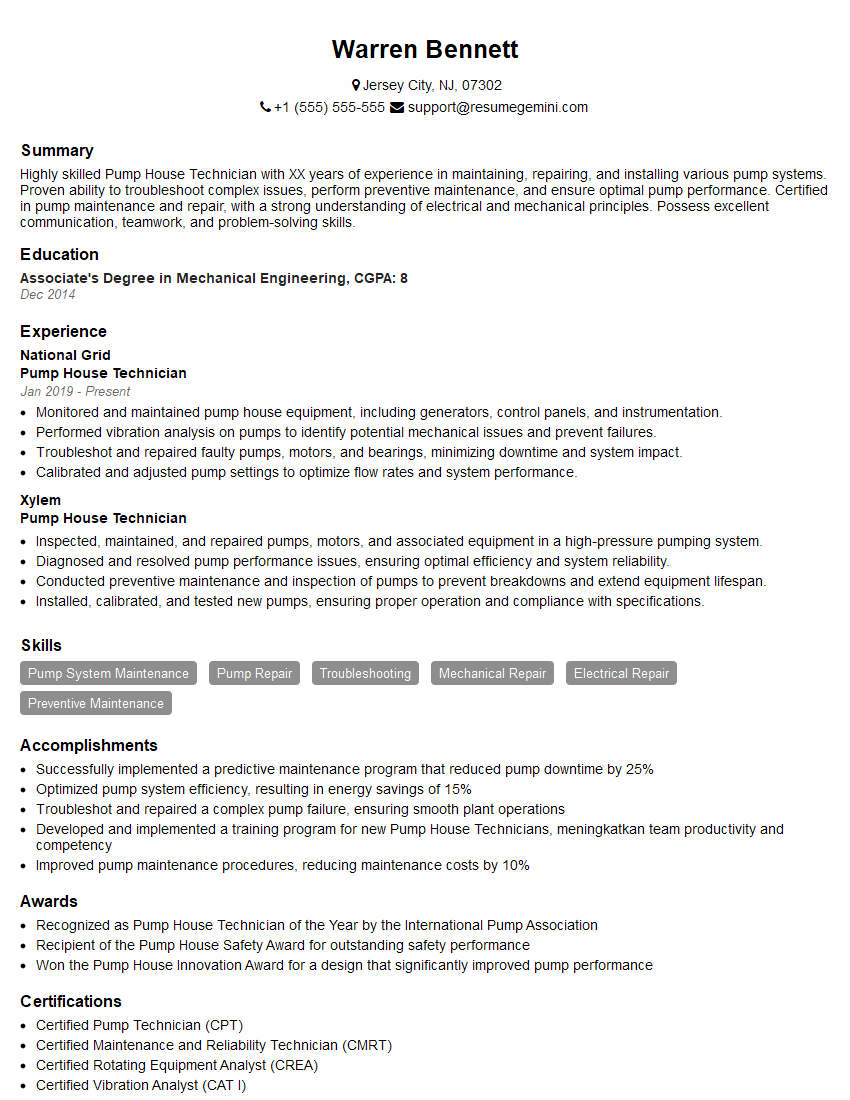

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pump House Technician

1. Explain the types of pumps used in pump houses and their applications.

There are various types of pumps used in pump houses, each designed for specific applications:

- Centrifugal Pumps: Widely used for transferring liquids, handling large volumes at relatively low pressures.

- Axial Flow Pumps: Suitable for high-flow, low-head applications, such as water circulation in cooling systems.

- Positive Displacement Pumps: Utilized when constant pressure or high viscosity fluids need to be handled, e.g., reciprocating pumps or gear pumps.

- Submersible Pumps: Designed to operate underwater, often used for well or tank applications.

- Slurry Pumps: Engineered to handle abrasive or corrosive fluids, such as in mining or industrial wastewater.

2. Describe the process of troubleshooting and repairing a centrifugal pump.

Troubleshooting:

- Inspect for leaks or blockages: Check for any damage or obstructions in the pump, piping, or valves.

- Test electrical components: Ensure the motor, controller, and wiring are functioning correctly.

- Measure pump performance: Monitor pressure, flow, and temperature readings to identify any deviations.

Repair:

- Replace worn or damaged parts: Seals, bearings, impellers, or other components that have failed.

- Clean or unclog the pump: Remove any debris or blockages that may obstruct flow.

- Adjust or calibrate the pump: Optimize performance by adjusting impeller clearances, flow rates, or pressure settings.

3. Explain the importance of maintaining pump efficiency and the methods used to achieve it.

Maintaining pump efficiency is crucial for optimal performance and energy savings:

- Regular inspections and maintenance: Proactively identify and address any issues that could impact efficiency.

- Proper alignment and lubrication: Ensure correct alignment to minimize friction and wear, and regularly lubricate moving parts.

- Optimal operating conditions: Operate pumps within their designated flow and pressure ranges, avoiding overloading or under-utilization.

- Utilizing energy-efficient pumps: Choose pumps with higher efficiency ratings or variable speed drives to reduce energy consumption.

- Monitoring and data analysis: Regularly monitor pump performance and analyze data to identify areas for improvement and optimization.

4. Describe the safety procedures and precautions necessary when working in a pump house.

Safety is paramount in a pump house environment:

- Wear appropriate PPE: Use protective clothing, gloves, eye protection, and earplugs as required.

- Lock out and tag out equipment: Isolate pumps and energy sources before performing any maintenance or repairs.

- Be aware of hazards: Identify potential risks, such as moving machinery, electrical hazards, or slippery surfaces.

- Follow proper lifting techniques: Use ergonomic practices to avoid injuries while handling heavy equipment.

- Work with a buddy: Have another person present for assistance and emergency situations.

5. Explain your experience with using vibration analysis to monitor pump health.

Vibration analysis is a valuable tool for assessing pump health:

- Data acquisition: Collect vibration data using sensors attached to the pump.

- Analysis and interpretation: Use specialized software to analyze data and identify any abnormal vibrations.

- Trend monitoring: Track vibration levels over time to detect changes or developing issues.

- Diagnosis and corrective actions: Identify the root cause of excessive vibrations, such as misalignment, bearing wear, or impeller imbalance, and take appropriate corrective measures.

- Predictive maintenance: Utilize vibration analysis as part of a predictive maintenance program to anticipate potential problems and prevent unplanned downtime.

6. Describe your experience with installing and commissioning new pumps.

Installing and commissioning new pumps requires precision and attention to detail:

- Site preparation: Ensure proper foundation and alignment for optimal pump performance.

- Piping and electrical connections: Connect piping, wiring, and instrumentation according to specifications.

- Initial startup: Supervise the initial startup of the pump, monitoring performance and making necessary adjustments.

- Testing and performance verification: Conduct performance tests to verify pump meets flow and pressure requirements.

- Documentation and training: Provide operational and maintenance documentation, and train personnel on pump operation.

7. Explain your knowledge of pump selection criteria.

Selecting the appropriate pump requires careful consideration of the following factors:

- Flow rate: Determine the required volume of liquid to be pumped.

- Head pressure: Calculate the pressure needed to overcome friction and elevation changes.

- Type of liquid: Consider the fluid characteristics, such as viscosity, density, and corrosiveness.

- Duty cycle: Specify the frequency and duration of pump operation.

- Efficiency and energy consumption: Prioritize pumps with higher efficiency ratings to minimize operating costs.

8. Describe your experience with managing pump inventories and spare parts.

Effective inventory management is crucial for pump house operations:

- Establishing inventory levels: Determine appropriate stock levels based on usage patterns and lead times.

- Monitoring inventory: Regularly track inventory levels to identify potential shortages.

- Purchasing and procurement: Order necessary supplies and spare parts based on demand.

- Storage and organization: Maintain proper storage conditions and organize parts for efficient retrieval.

- Inventory control systems: Utilize inventory management software or systems to streamline processes.

9. Explain your understanding of the principles of fluid dynamics as they relate to pump operation.

Fluid dynamics plays a vital role in pump operation:

- Fluid flow: Understand principles of fluid flow, velocity, and pressure.

- Pump performance curves: Interpret pump curves to determine flow, head, and efficiency characteristics.

- Cavitation: Identify and prevent cavitation, which can damage pump components.

- Friction and energy loss: Calculate friction losses and optimize system design to minimize energy consumption.

- NPSH requirements: Ensure adequate Net Positive Suction Head (NPSH) to prevent cavitation.

10. Describe your experience with troubleshooting and repairing electrical components of pumps.

Electrical troubleshooting skills are essential for pump house technicians:

- Basic electrical principles: Understand electrical circuits, wiring diagrams, and component functions.

- Testing and diagnostic tools: Use multimeters, insulation testers, and oscilloscopes to identify electrical issues.

- Motor troubleshooting: Diagnose and repair common motor problems, such as overheating, winding failures, or starter malfunctions.

- Control system troubleshooting: Resolve issues with pump controllers, sensors, and instrumentation.

- Wiring and protection: Ensure proper wiring, connections, and protection devices are in place.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pump House Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pump House Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pump House Technicians are responsible for the operation and maintenance of pump stations, ensuring that they operate efficiently and reliably. Their key responsibilities include:

1. Operation and Monitoring

• Starting, stopping, and adjusting pumps to maintain desired flow rates and pressures

• Monitoring pump performance and identifying any deviations from normal operating parameters

• Responding to alarms and taking corrective actions to minimize disruptions

2. Maintenance and Repair

• Performing preventive maintenance tasks, such as lubricating, cleaning, and inspecting pumps

• Troubleshooting and repairing pumps, motors, and associated equipment

• Replacing worn or damaged parts and ensuring that all equipment is in good working order

3. Calibration and Testing

• Calibrating and testing pumps, meters, and other instrumentation to ensure accuracy

• Performing functional tests to verify that pumps are operating as intended

• Maintaining records of all maintenance, repairs, and tests

4. Safety and Compliance

• Adhering to all safety protocols and procedures

• Ensuring that the pump station meets all applicable environmental regulations

• Providing training and guidance to other staff on safety and compliance

Interview Tips

To prepare for a Pump House Technician interview, candidates should focus on demonstrating their technical skills and knowledge, as well as their understanding of the industry and safety regulations. Here are some tips:

1. Research the Company and Position

• Visit the company’s website to learn about their business and operations

• Research the specific pump station you will be working at

• Review the job description carefully to identify the key requirements

2. Prepare for Technical Questions

• Brush up on your knowledge of pump operation and maintenance

• Practice troubleshooting common pump problems

• Be prepared to discuss your experience with pump calibration and testing

3. Highlight Your Safety Awareness

• Emphasize your commitment to safety and your knowledge of industry regulations

• Provide examples of how you have prioritized safety in your previous roles

• Explain how you would ensure the safety of yourself and others in a pump station environment

4. Showcase Your Communication Skills

• Be clear and concise in your answers

• Use examples to illustrate your points

• Be prepared to answer questions about your experience working with others

5. Prepare Questions for the Interviewer

• Asking thoughtful questions shows that you are engaged and interested in the position

• Prepare questions about the company, the pump station, and the specific role

• Avoid asking generic or unrelated questions

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pump House Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!