Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pump Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

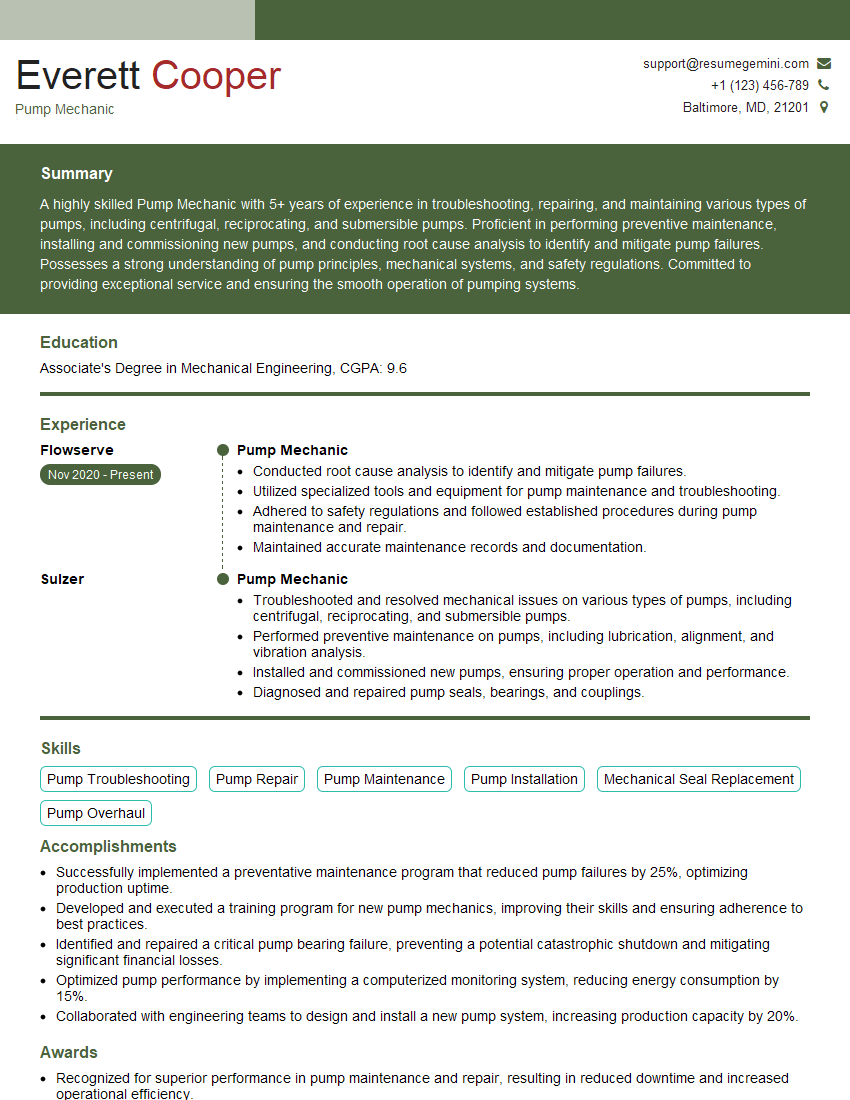

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pump Mechanic

1. What are the common types of pumps you have worked on?

In my previous role, I have worked on various types of pumps, including:

- Centrifugal pumps

- Reciprocating pumps

- Rotary pumps

- Submersible pumps

- Vacuum pumps

2. Describe the process of troubleshooting a pump that is not delivering the desired flow rate.

Initial Inspection

- Check the power supply and ensure the pump is receiving the correct voltage and amperage.

- Inspect the pump’s exterior for any visible damage or leaks.

- Listen for any unusual noises or vibrations coming from the pump.

Performance Assessment

- Use a flow meter to measure the actual flow rate and compare it to the desired flow rate.

- Check the pump’s pressure gauges to ensure it is operating within the specified pressure range.

- Monitor the pump’s temperature to rule out any overheating issues.

Mechanical Inspection

- Disassemble the pump and inspect the impeller, casing, and other internal components for wear, damage, or debris.

- Check the bearings and seals for signs of wear or leakage.

- Examine the pump’s shaft for any misalignment or damage.

Electrical Inspection

- Check the electrical connections to ensure they are secure and free of corrosion.

- Use a multimeter to test the continuity of the motor windings and the resistance of the starter.

- Inspect the motor for any signs of overheating or damage.

3. What are the key factors to consider when selecting a pump for a specific application?

- Flow rate requirements

- Pressure requirements

- Fluid properties (viscosity, temperature, corrosivity, etc.)

- Available power sources

- Space constraints

- Cost considerations

- Maintenance requirements

4. How do you ensure that a pump is properly installed and aligned?

- Follow the manufacturer’s installation instructions carefully.

- Use a level to ensure the pump is installed horizontally or vertically, as per the specifications.

- Align the pump’s shaft with the motor shaft using a laser alignment tool.

- Tighten all bolts and connections securely.

- Perform a test run to ensure the pump is operating smoothly and without vibrations.

5. What are the common maintenance procedures for pumps?

- Regular lubrication of bearings and seals

- Inspection of impellers and casings for wear and damage

- Monitoring of vibration levels

- Replacement of worn or damaged components

- Flushing and cleaning of the pump to remove debris and contaminants

6. How do you handle a situation where a pump is experiencing excessive vibration?

- Stop the pump immediately to prevent further damage.

- Check the pump’s alignment and ensure it is properly connected to the motor.

- Inspect the bearings and seals for signs of wear or damage.

- Examine the impeller and casing for any foreign objects or debris that may be causing the vibration.

- Balance the impeller to eliminate any weight imbalances.

- If necessary, replace any worn or damaged components and reassemble the pump.

7. What are the safety precautions you take when working on pumps?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Lock out and tag out the power supply before performing any maintenance or repairs.

- Ensure the pump is depressurized before opening any covers or connections.

- Use proper lifting techniques when handling heavy components.

- Be aware of the potential hazards of the fluid being pumped, such as toxicity or flammability.

8. What are the different types of pump seals and their applications?

- Mechanical seals: Used in applications where there is high pressure or a need for leak-free operation. They consist of two mating faces that are held together by a spring or bellow.

- Lip seals: Used in low-pressure applications where some leakage is acceptable. They consist of a rubber lip that contacts a rotating shaft.

- Gaskets: Used to create a seal between two surfaces. They are typically made of rubber, cork, or paper.

- O-rings: Used to create a seal between two cylindrical surfaces. They are typically made of rubber or elastomer.

9. Explain the function of a pump impeller and how it affects pump performance.

The impeller is a rotating component that imparts energy to the fluid being pumped. It consists of a series of blades or vanes that are attached to a hub. As the impeller rotates, the fluid enters the eye of the impeller and is accelerated by the blades. This acceleration creates pressure and flow in the fluid.

- Impeller diameter: The larger the impeller diameter, the greater the flow rate and pressure.

- Impeller blade design: The shape and angle of the impeller blades affect the pump’s efficiency and head.

- Impeller material: The material of the impeller must be compatible with the fluid being pumped.

10. Describe the purpose of a pump diffuser and how it contributes to pump efficiency.

A pump diffuser is a stationary component that is located downstream of the impeller. It consists of a series of vanes or channels that gradually increase in size. As the fluid exits the impeller, it enters the diffuser, where its velocity is reduced and its pressure is increased. This process helps to convert the kinetic energy of the fluid into pressure energy, which increases the pump’s overall efficiency.

- Diffuser vane design: The shape and angle of the diffuser vanes affect the pump’s efficiency and head.

- Diffuser material: The material of the diffuser must be compatible with the fluid being pumped.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pump Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pump Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pump Mechanics install, maintain, and repair pumps used in various industries, such as oil and gas, water treatment, and manufacturing. Their responsibilities include:

1. Installation and Repair

Install and repair pumps in accordance with blueprints and specifications

- Inspect pumps for wear and tear, and make necessary repairs or replacements

- Adjust and align pumps to ensure optimal performance

2. Troubleshooting and Maintenance

Troubleshoot and diagnose pump problems, and perform necessary repairs

- Conduct routine maintenance on pumps to prevent breakdowns and extend their lifespan

- Monitor pump performance and identify potential problems

3. Communication and Documentation

Communicate with maintenance staff, engineers, and other personnel to coordinate repairs and maintenance

- Document maintenance and repair work, including parts used and labor hours

- Provide technical advice and support to other maintenance personnel

4. Safety and Regulations

Follow safety regulations and procedures when working with pumps

- Ensure that pumps are operated in a safe manner

- Comply with environmental regulations related to pump operation and maintenance

Interview Tips

Preparing for an interview for a Pump Mechanic position involves understanding the job responsibilities and developing strategies to showcase your skills and experience. Here are some interview tips to help you ace your interview:

1. Research the Company and Position

Before the interview, research the company and the specific Pump Mechanic position you are applying for. This will help you understand the company’s needs and align your answers to their requirements.

- Visit the company website to learn about their products, services, and culture.

- Read industry publications and news articles to stay up-to-date on the latest trends and technologies in pump maintenance.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers. This will help you articulate your skills and experience clearly and confidently.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Highlight your technical skills, problem-solving abilities, and commitment to safety.

3. Emphasize Your Safety Knowledge

Safety is paramount in pump maintenance. Emphasize your knowledge of safety regulations and procedures during the interview.

- Explain your experience in following safety protocols and preventing accidents.

- Discuss your understanding of potential hazards associated with pump operations.

4. Showcase Your Communication Skills

Effective communication is crucial for coordinating repairs and working with other maintenance personnel. Highlight your communication skills during the interview.

- Provide examples of how you have effectively communicated with colleagues and resolved technical issues.

- Emphasize your ability to document maintenance work clearly and accurately.

5. Ask Thoughtful Questions

Preparing thoughtful questions to ask the interviewer demonstrates your interest and engagement. Questions about the company’s safety culture, maintenance procedures, and growth opportunities are appropriate.

- Inquire about the company’s commitment to safety and environmental compliance.

- Ask about the opportunities for professional development and career advancement.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Pump Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Pump Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.