Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pump Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

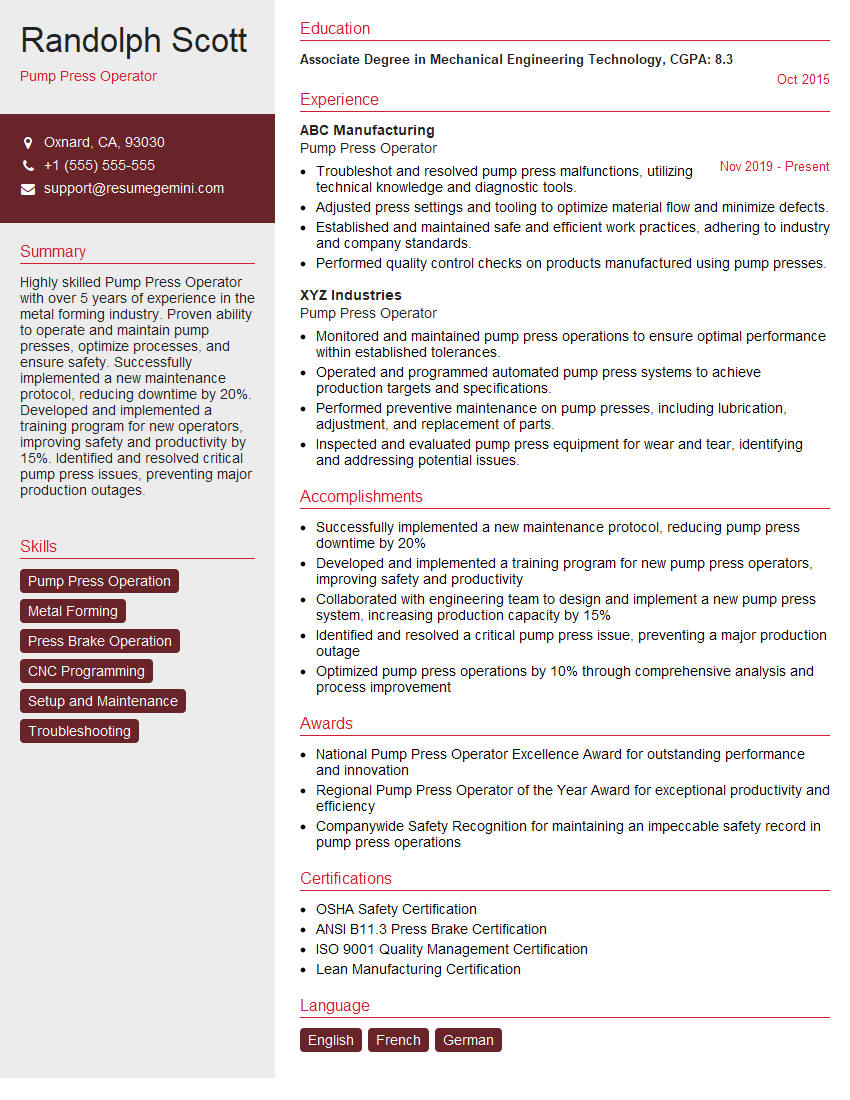

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pump Press Operator

1. Describe the process of setting up a pump press for a new job.

Setting up a pump press for a new job involves several steps:

- Mount the die: Install the appropriate upper and lower die sets into the press.

- Adjust the press bed: Set the bed height to accommodate the workpiece thickness.

- Set the slide stroke: Determine and set the optimal stroke length for the forming operation.

- Set the pressure: Adjust the press pressure to achieve the desired forming force.

- Calibrate the press: Perform necessary calibrations to ensure accurate press operation and part quality.

2. How do you ensure the quality of parts produced by the pump press?

Material Verification

- Inspect raw materials to meet specifications.

- Check for defects or inconsistencies.

Equipment Maintenance

- Regularly maintain and calibrate the press.

- Monitor press parameters for any deviations.

Process Control

- Follow established process parameters.

- Monitor and adjust parameters as needed.

- Inspect parts at critical checkpoints.

3. Explain the different types of pumps used in a pump press.

Pump presses utilize various types of pumps, including:

- Hydraulic pumps: Provide hydraulic pressure to the press cylinder for force generation.

- Pneumatic pumps: Use compressed air to power the press cylinder.

- Hand pumps: Manually operated pumps for small-scale or low-force applications.

- Electric pumps: Motor-driven pumps for continuous and automated operation.

- Variable displacement pumps: Allow adjustment of pump output flow and pressure.

4. How do you troubleshoot common problems with a pump press?

Troubleshooting common problems with a pump press involves:

- Pressure issues: Check hydraulic lines, pumps, and valves for leaks or blockages.

- Stroke issues: Verify slide stroke settings, check hydraulic cylinder components, and inspect for mechanical obstructions.

- Part quality issues: Analyze die condition, material quality, and process parameters.

- Electrical issues: Check power supply, electrical connections, and control systems.

- Safety issues: Inspect safety guards, interlocks, and emergency stop mechanisms.

5. Describe the importance of safety when operating a pump press.

Safety is paramount when operating a pump press:

- Training and Authorization: Only trained and authorized personnel should operate the press.

- Protective Gear: Wear appropriate safety gear, including gloves, eye protection, and earplugs.

- Machine Guards: Ensure all safety guards and interlocks are in place and functional.

- Clearance from Machine: Maintain a safe distance from the press during operation.

- Emergency Stop Awareness: Familiarize yourself with the emergency stop button and its usage.

6. Explain the different types of materials that can be formed using a pump press.

Pump presses can form a wide range of materials, including:

- Metals: Steel, aluminum, copper, and brass.

- Plastics: Thermoplastics, thermosets, and composites.

- Rubber: Natural and synthetic rubber compounds.

- Wood: Plywood, MDF, and hardwoods.

- Leather: Animal hide and synthetic leather.

7. How do you maintain a hydraulic system on a pump press?

Maintaining a hydraulic system on a pump press involves:

- Fluid Management: Monitor fluid levels, check for leaks, and replace fluids as required.

- Filter Inspection and Replacement: Regularly inspect and replace filters to remove contaminants.

- Pump Maintenance: Inspect pumps for wear and tear, and perform repairs or replacements when necessary.

- Valve Maintenance: Inspect and lubricate valves to ensure proper operation.

- Hose and Line Inspection: Check hoses and lines for damage or leaks, and replace as needed.

8. Explain the purpose of a die cushion on a pump press.

A die cushion on a pump press serves several purposes:

- Supporting the workpiece: The cushion provides support to the workpiece during the forming process.

- Controlling part shape: The cushion helps maintain the desired part shape and prevent buckling or deformation.

- Ejecting the part: After forming, the cushion can be used to eject the part from the die.

- Reducing noise and vibration: The cushion absorbs impact forces, reducing noise and vibration during the press cycle.

9. Describe the different types of press brakes used in pump press operations.

There are various types of press brakes used in pump press operations:

- Mechanical Press Brakes: Utilize a mechanical drive system for precise bending operations.

- Hydraulic Press Brakes: Employ hydraulic cylinders for high-force bending applications.

- Electric Press Brakes: Offer precise control and flexibility with electric motors.

- CNC Press Brakes: Computer-controlled brakes for complex and repetitive bending jobs.

- Tandem Press Brakes: Combine multiple press brakes for increased bending capacity.

10. How do you calibrate a pump press to ensure accurate forming results?

Calibrating a pump press involves several steps:

- Pressure Calibration: Using a pressure gauge, calibrate the pump to deliver the desired hydraulic pressure for forming.

- Stroke Calibration: Set and verify the press stroke length to achieve the required forming depth.

- Die Clearance Calibration: Determine and adjust the die clearance to ensure proper material flow and part quality.

- Safety Calibration: Check and calibrate safety interlocks and emergency stop mechanisms.

- Validation: Perform test runs and inspect parts to confirm calibration accuracy.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pump Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pump Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pump Press Operators play a crucial role in manufacturing processes by operating and maintaining pump presses. Their primary responsibilities include:

1. Machine Operation

Operate pump presses precisely to produce high-quality parts or products.

- Set up and adjust press settings according to job requirements and specifications.

- Monitor equipment during operation to ensure proper functioning and safety.

2. Material Handling

Handle raw materials and finished products efficiently to ensure a smooth production process.

- Inspect raw materials to ensure they meet specifications and quality standards.

- Load and unload materials and parts onto and from the press bed.

3. Quality Control

Perform quality checks on produced parts to ensure adherence to standards.

- Inspect parts for defects, dimensions, and functionality.

- Report any out-of-range products or process deviations promptly.

4. Equipment Maintenance

Maintain and troubleshoot pump presses to ensure optimal performance.

- Conduct routine inspections and preventive maintenance tasks.

- Identify and troubleshoot equipment malfunctions, performing repairs as necessary.

Interview Tips

To maximize your chances of success in a pump press operator interview, it’s essential to prepare effectively and demonstrate your skills and knowledge. Here are some interview tips and strategies:

1. Research the Company and Position

Familiarize yourself with the company’s history, products or services, and culture. Understand the specific requirements of the pump press operator position and how your skills align with them.

- Visit the company website and social media pages.

- Read industry news and articles to stay updated on trends and best practices.

2. Practice Common Interview Questions

Prepare answers to common interview questions, such as those related to your experience, skills, and motivations. Anticipate technical questions specific to pump press operation and be ready to discuss your knowledge and expertise.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific examples.

- Practice answering questions aloud to improve your delivery and confidence.

3. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are most relevant to the pump press operator position. Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your knowledge of press operations, including setup, maintenance, and troubleshooting.

- Describe your experience in handling materials, performing quality checks, and maintaining work areas.

4. Be Enthusiastic and Professional

Approach the interview with enthusiasm and a professional demeanor. Dress appropriately, arrive on time, and maintain eye contact during the conversation. Ask thoughtful questions to demonstrate your interest and engagement.

- Prepare questions about the company’s operations, training opportunities, and safety protocols.

- Express your eagerness to contribute to the team and add value to the organization.

5. Follow Up and Thank the Interviewers

After the interview, send a thank-you note to the interviewers, reiterating your interest in the position and highlighting your key qualifications. You can also inquire about the next steps in the hiring process and express your appreciation for their time and consideration.

- Keep your follow-up note brief and professional.

- Proofread your note carefully before sending it.

Next Step:

Now that you’re armed with the knowledge of Pump Press Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pump Press Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini