Are you gearing up for a career in Pump Servicer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pump Servicer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

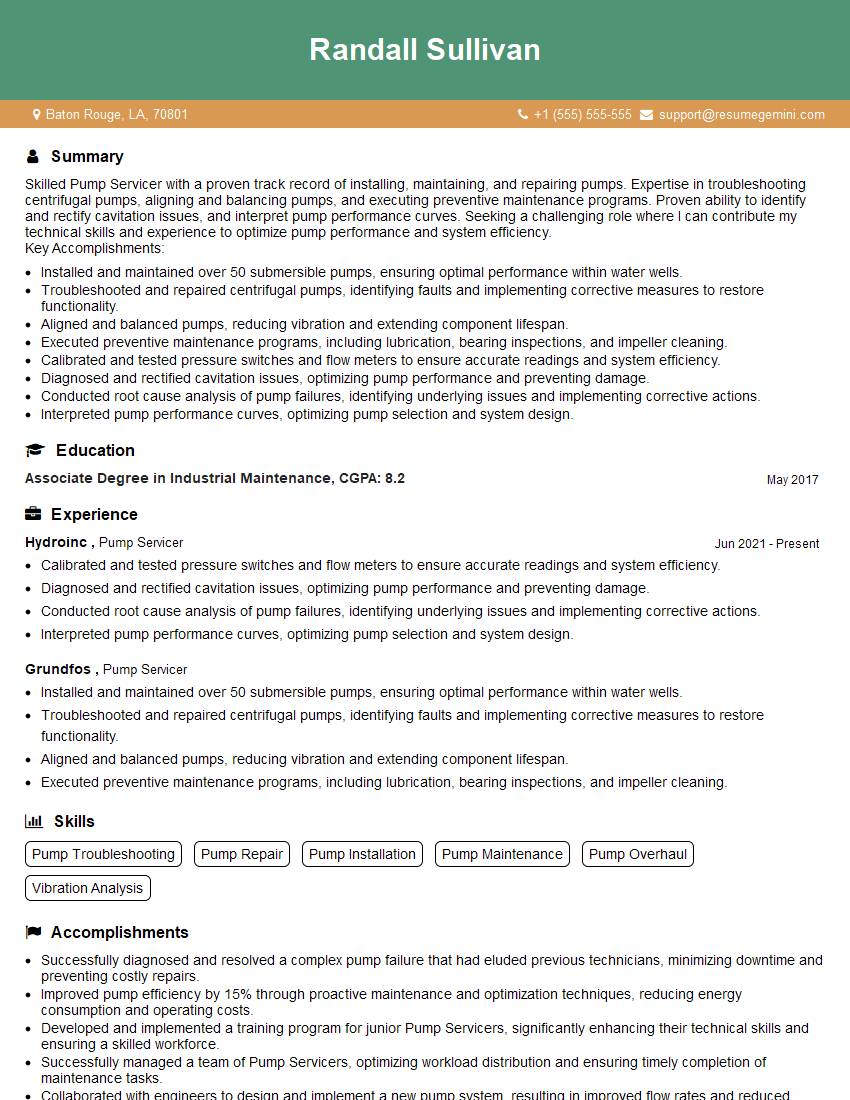

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pump Servicer

1. Describe the steps involved in troubleshooting a centrifugal pump that is not delivering the required flow rate.

- Check the pump’s suction line for any blockages or leaks.

- Verify that the pump’s impeller is not clogged or damaged.

- Inspect the pump’s discharge line for any blockages or leaks.

- Measure the pump’s discharge pressure and compare it to the manufacturer’s specifications.

- Check the pump’s motor for any electrical problems.

2. What are the different types of seals used in pumps and what are their advantages and disadvantages?

Mechanical Seals

- Advantages: Long lifespan, reliable operation, low maintenance.

- Disadvantages: Can be expensive, require specialized installation and maintenance.

Packing Seals

- Advantages: Inexpensive, easy to install and maintain.

- Disadvantages: Short lifespan, less reliable than mechanical seals, require frequent maintenance.

Lip Seals

- Advantages: Compact, inexpensive, easy to install.

- Disadvantages: Short lifespan, not suitable for high-pressure applications.

3. How do you calculate the head and flow rate of a pump?

- Head = (Pressure difference / Specific gravity) + (Velocity head / 2g)

- Flow rate = (Pump discharge area * Pump speed) / 1000

4. What are the different types of pump impellers and what are their applications?

- Closed Impellers: Used for low-flow, high-pressure applications.

- Semi-Open Impellers: Used for medium-flow, medium-pressure applications.

- Open Impellers: Used for high-flow, low-pressure applications.

5. What are the safety precautions that should be followed when working with pumps?

- Always wear appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Never work on a pump that is running.

- Ensure that the pump is properly grounded.

- Be aware of the potential hazards of the fluid being pumped.

- Follow all manufacturer’s instructions for safe operation.

6. What are the different types of pump maintenance and how often should they be performed?

- Routine Maintenance: Performed on a regular basis (e.g., weekly or monthly) and includes tasks such as checking lubrication levels, inspecting seals, and cleaning the pump.

- Preventive Maintenance: Performed less frequently (e.g., annually) and includes tasks such as replacing seals, bearings, and impellers.

- Corrective Maintenance: Performed when a pump fails or experiences a problem and includes tasks such as repairing or replacing damaged components.

7. What are the factors that affect the efficiency of a pump?

- Pump design (e.g., impeller type, casing shape)

- Pump speed

- Fluid properties (e.g., viscosity, temperature)

- System conditions (e.g., suction head, discharge head)

- Maintenance and operating conditions

8. What are the different types of pump controls and how do they work?

- Variable Frequency Drives (VFDs): Control pump speed to adjust flow rate and pressure.

- Discharge Pressure Regulators: Maintain a constant discharge pressure by adjusting pump speed or bypass valve.

- Suction Pressure Regulators: Maintain a constant suction pressure by adjusting pump speed or inlet valve.

- Flow Switches: Turn the pump on or off based on flow rate.

- Pressure Switches: Turn the pump on or off based on discharge pressure.

9. What are the common causes of pump failure and how can they be prevented?

- Mechanical failure (e.g., bearing failure, impeller damage)

- Electrical failure (e.g., motor burnout, wiring issues)

- Hydraulic failure (e.g., cavitation, overheating)

- Maintenance neglect (e.g., lack of lubrication, improper installation)

10. How do you stay up-to-date on the latest advances and best practices in pump technology?

- Attend industry conferences and workshops.

- Read industry publications and technical articles.

- Participate in online forums and social media groups.

- Consult with pump manufacturers and experts.

- Obtain industry certifications and training.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pump Servicer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pump Servicer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pump Servicers are responsible for the installation, maintenance, and repair of pumps in various industrial and commercial settings. They work closely with customers to identify and resolve issues, ensuring that pumps are operating efficiently and safely. Key job responsibilities include:

1. Installation and Commissioning

Installing new pumps and ensuring they are properly connected and calibrated.

- Following blueprints and technical specifications.

- Using specialized tools and equipment to connect pumps to pipes and electrical systems.

2. Maintenance and Inspections

Conducting regular inspections to identify potential issues and prevent breakdowns.

- Checking pump components for wear and tear.

- Lubricating moving parts and replacing worn seals.

3. Troubleshooting and Repairs

Diagnosing and repairing faulty pumps.

- Using troubleshooting techniques to identify the root cause of problems.

- Replacing defective parts or components.

4. Field Service

Responding to customer calls and providing on-site support.

- Conducting emergency repairs to minimize downtime.

- Providing technical advice and training to customers.

Interview Tips

Preparing for a Pump Servicer interview requires thorough research and practice. Here are some tips to help candidates ace the interview:

1. Research the Company and Role

Learn about the company’s industry, products, and services. Understand the specific responsibilities of the Pump Servicer role and how it aligns with your skills and experience.

- Visit the company’s website and social media pages.

- Review the job description carefully.

2. Practice Common Interview Questions

Prepare answers to common interview questions related to your technical skills, problem-solving abilities, and customer service experience.

- Describe a time you successfully diagnosed and repaired a faulty pump.

- How do you prioritize tasks when handling multiple customer requests?

3. Highlight Relevant Experience

Emphasize your relevant experience in pump installation, maintenance, and repair. Use specific examples and quantifiable results to demonstrate your abilities.

- Showcase your experience with different types of pumps and industrial equipment.

- Mention any certifications or training you have completed.

4. Demonstrate Problem-Solving Skills

Provide examples of how you have successfully solved complex technical problems in the past. This highlights your critical thinking and analytical abilities.

- Describe a situation where you used troubleshooting techniques to resolve a pump issue.

- Explain how you prioritize and manage multiple tasks in a high-pressure environment.

5. Express Enthusiasm and Professionalism

Show your enthusiasm for the role and the industry. Be professional, respectful, and ask thoughtful questions about the company and the position.

- Express your interest in the company’s products and services.

- Ask questions about the company’s growth plans and the potential for career advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pump Servicer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!