Feeling lost in a sea of interview questions? Landed that dream interview for Pump Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pump Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

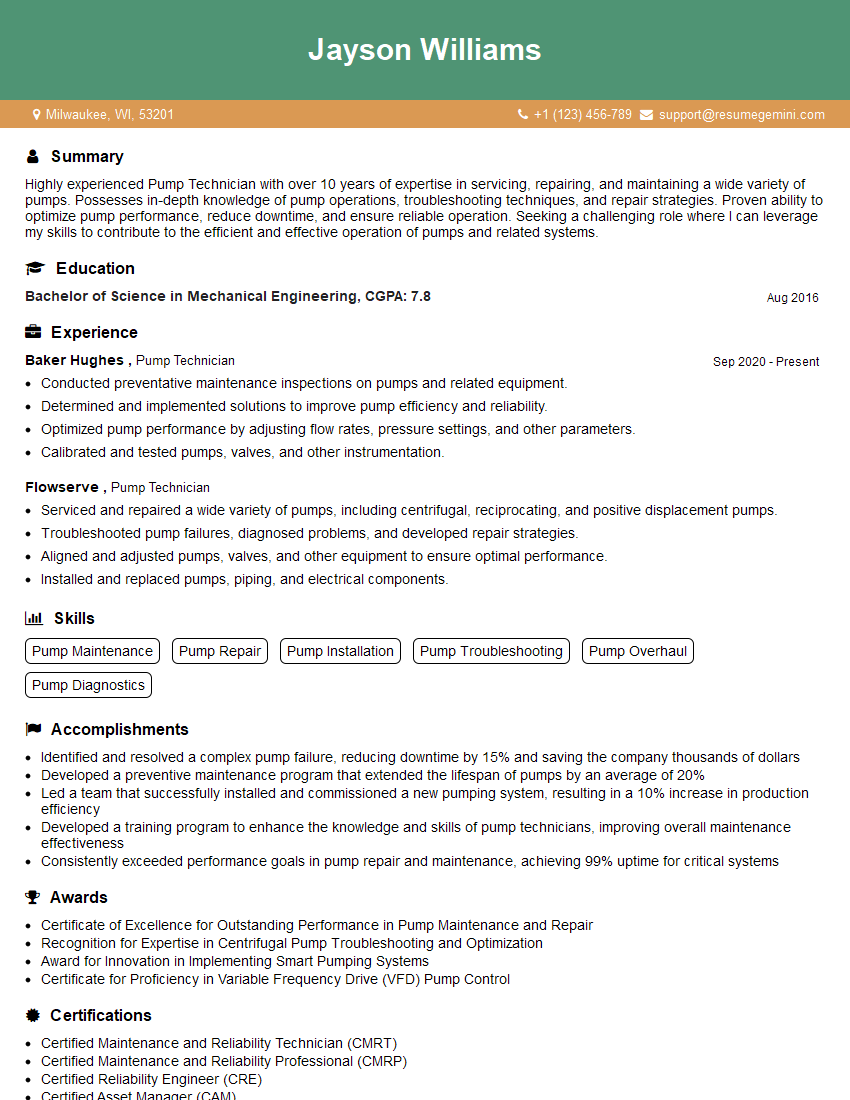

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pump Technician

1. Explain the different types of pumps and their applications.

- Centrifugal pumps: These are the most common type of pump and are used to move liquids by centrifugal force. They are suitable for a wide range of applications, including water supply, wastewater treatment, and industrial processes.

- Positive displacement pumps: These pumps use a positive displacement mechanism to move liquids. They are suitable for applications where a high pressure or flow rate is required.

- Jet pumps: These pumps use a jet of fluid to create a vacuum that draws liquid into the pump. They are suitable for applications where the liquid is contaminated or contains solids.

2. What are the key components of a pump and what is their function?

- Impeller: The impeller is the rotating component of the pump that creates the centrifugal force that moves the liquid.

- Casing: The casing is the stationary component of the pump that surrounds the impeller and directs the flow of liquid.

- Shaft: The shaft connects the impeller to the motor and transmits power to the impeller.

- Bearings: The bearings support the shaft and allow it to rotate smoothly.

- Seals: The seals prevent leakage of liquid from the pump.

3. What are the different materials used in the construction of pumps and what are their advantages and disadvantages?

- Cast iron: Cast iron is a strong and durable material that is resistant to wear and corrosion. However, it is also heavy and expensive.

- Stainless steel: Stainless steel is a corrosion-resistant material that is easy to clean. However, it is more expensive than cast iron.

- Bronze: Bronze is a strong and durable material that is resistant to corrosion. However, it is more expensive than cast iron and stainless steel.

- Plastic: Plastic is a lightweight and inexpensive material that is resistant to corrosion. However, it is not as strong as cast iron or stainless steel.

4. What are the different types of pump drives and what are their advantages and disadvantages?

- Electric motors: Electric motors are the most common type of pump drive. They are reliable and efficient, but they can be expensive to purchase and operate.

- Diesel engines: Diesel engines are a good option for applications where there is no access to electricity. They are powerful and reliable, but they can be noisy and expensive to operate.

- Gasoline engines: Gasoline engines are a good option for small pumps. They are lightweight and inexpensive, but they can be noisy and less efficient than electric motors.

5. What are the different types of pump controls and what are their advantages and disadvantages?

- Manual controls: Manual controls allow the operator to start and stop the pump manually. They are simple and inexpensive, but they require the operator to be present to operate the pump.

- Automatic controls: Automatic controls allow the pump to start and stop automatically based on a set of conditions. They are more expensive than manual controls, but they can save energy and improve the performance of the pump.

6. What are the different types of pump maintenance and how often should they be performed?

- Daily maintenance: Daily maintenance includes tasks such as checking the oil level, greasing the bearings, and inspecting the pump for leaks.

- Weekly maintenance: Weekly maintenance includes tasks such as cleaning the pump, checking the impeller for wear, and tightening the bolts.

- Monthly maintenance: Monthly maintenance includes tasks such as changing the oil, inspecting the electrical connections, and calibrating the controls.

- Yearly maintenance: Yearly maintenance includes tasks such as overhauling the pump, replacing the bearings, and inspecting the shaft for wear.

7. What are the different types of pump troubleshooting and how can they be resolved?

- Pump is not starting: Check the power supply, the motor, and the controls.

- Pump is not pumping: Check the impeller, the casing, and the seals.

- Pump is leaking: Check the seals, the bearings, and the casing.

- Pump is making noise: Check the bearings, the impeller, and the shaft.

8. What are the different types of pump safety precautions and how can they be implemented?

- Lock out/tag out the pump before performing any maintenance or repairs.

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Follow the manufacturer’s instructions for operating and maintaining the pump.

- Inspect the pump regularly for leaks, wear, and other damage.

- Train all employees who operate or maintain pumps on the proper safety procedures.

9. What are the latest trends in pump technology?

- The use of variable speed drives (VSDs) to improve the efficiency of pumps.

- The development of new materials that are more resistant to wear and corrosion.

- The use of advanced controls to improve the performance and reliability of pumps.

- The development of new pump designs that are more efficient and environmentally friendly.

10. What are the challenges facing the pump industry?

- The need to improve the efficiency of pumps to reduce energy consumption.

- The need to develop new materials that are more resistant to wear and corrosion.

- The need to develop new pump designs that are more efficient and environmentally friendly.

- The need to address the skills gap in the pump industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pump Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pump Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pump Technicians are responsible for the installation, maintenance, and repair of pumps and pumping systems. They work in a variety of settings, including industrial, commercial, and residential buildings. Key job responsibilities include:

1. Installation of Pumps

Pump Technicians install pumps and pumping systems according to specifications. They ensure that the pumps are properly aligned and connected, and that they are operating efficiently.

2. Maintenance of Pumps

Pump Technicians perform regular maintenance on pumps and pumping systems. They inspect the pumps for wear and tear, and they replace any worn or damaged parts. They also lubricate the pumps and adjust the settings as needed.

3. Repair of Pumps

Pump Technicians repair pumps and pumping systems that have broken down. They troubleshoot the problem and identify the cause of the failure. They then repair or replace the damaged parts and test the pump to ensure that it is operating properly.

4. Troubleshooting

Pump Technicians troubleshoot problems with pumps and pumping systems. They identify the source of the problem and recommend solutions. They may also provide training to other staff on how to troubleshoot and repair pumps.

Interview Tips

Preparing for an interview for a Pump Technician position can help you make a great impression on the hiring manager and increase your chances of getting the job. Here are a few tips to help you prepare:

1. Research the Company

Before the interview, take some time to research the company you are applying to. Learn about their products or services, their history, and their culture. This will help you understand the company’s needs and how your skills and experience can benefit them.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you can expect to be asked in an interview for a Pump Technician position. These questions may include:

- Tell me about your experience with pump installation, maintenance, and repair.

- What are some of the challenges you have faced in your previous role as a Pump Technician?

- How do you stay up-to-date on the latest trends in pump technology?

3. Be Prepared to Discuss Your Skills and Experience

In addition to answering common interview questions, you should also be prepared to discuss your skills and experience in detail. Be able to provide specific examples of your work and how you have contributed to the success of your previous employer.

4. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing a suit or business casual attire. Make sure your clothes are clean and pressed, and that you are well-groomed.

5. Be Yourself

The most important thing is to be yourself in your interview. The hiring manager wants to get to know the real you, so don’t try to be someone you’re not. Be honest and genuine, and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pump Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!