Are you gearing up for a career in Pumper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pumper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

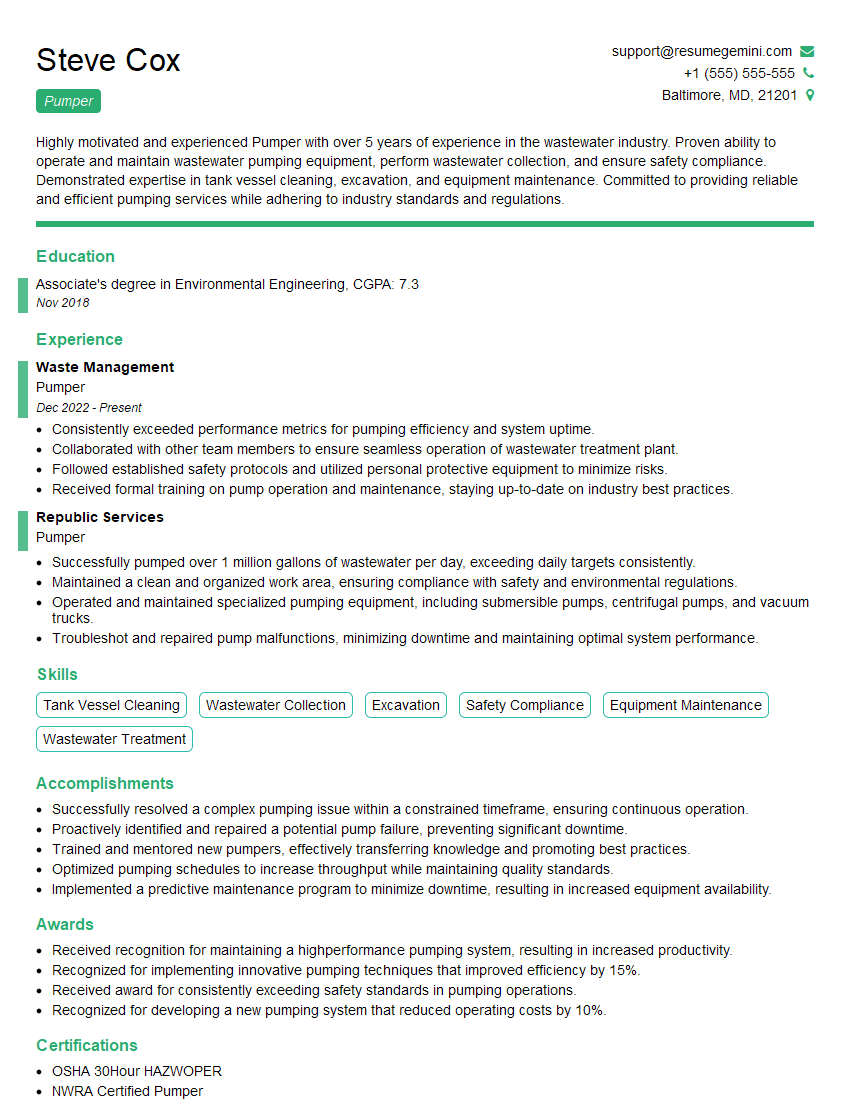

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pumper

1. Explain the difference between a centrifugal pump and a positive displacement pump?

A centrifugal pump and a positive displacement pump are essentially different in their operating principles:

- Centrifugal pump: Uses rotating impellers to create centrifugal force, which accelerates the fluid outward from the center of the pump. The velocity of the fluid increases as it moves away from the center, and this increased velocity creates pressure, which forces the fluid through the discharge port. Centrifugal pumps are typically used for high-flow, low-pressure applications.

- Positive displacement pump: Uses a variety of mechanisms, such as pistons, gears, or diaphragms, to trap and move a fixed volume of fluid. The volume of fluid displaced by the pump is directly proportional to the speed of the pump. Positive displacement pumps are typically used for low-flow, high-pressure applications.

2. Describe the different types of centrifugal pumps?

Single-stage pumps

- Single-stage pumps use a single impeller to raise the pressure of the fluid. They are typically used for low-pressure applications.

Multi-stage pumps

- Multi-stage pumps use multiple impellers to raise the pressure of the fluid. They are typically used for high-pressure applications.

End-suction pumps

- End-suction pumps have the suction port located at the end of the pump. They are typically used for applications where the fluid level is above the pump.

Side-suction pumps

- Side-suction pumps have the suction port located on the side of the pump. They are typically used for applications where the fluid level is below the pump.

Vertical pumps

- Vertical pumps have the shaft positioned vertically. They are typically used for applications where the pump must be submerged in the fluid.

3. What are the different types of positive displacement pumps?

- Reciprocating pumps: Use a piston or diaphragm to move the fluid. Reciprocating pumps are typically used for high-pressure applications.

- Rotary pumps: Use rotating gears or vanes to move the fluid. Rotary pumps are typically used for low-pressure applications.

4. How do you calculate the flow rate of a pump?

The flow rate of a pump is calculated using the following formula:

- Q = V * N

- where:

- Q = flow rate (in gallons per minute)

- V = volume of fluid displaced by the pump per revolution (in gallons per revolution)

- N = speed of the pump (in revolutions per minute)

5. How do you calculate the head of a pump?

The head of a pump is calculated using the following formula:

- H = P / (SG * g)

- where:

- H = head (in feet)

- P = pressure (in pounds per square inch)

- SG = specific gravity of the fluid

- g = acceleration due to gravity (in feet per second squared)

6. How do you select the right pump for a particular application?

The following factors should be considered when selecting a pump for a particular application:

- Flow rate

- Head

- Fluid type

- Temperature

- Pressure

- NPSH

7. What is NPSH?

- NPSH stands for Net Positive Suction Head. It is the minimum pressure that must be maintained at the suction port of a pump to prevent cavitation.

8. What is cavitation?

- Cavitation is the formation of vapor bubbles in a fluid due to a decrease in pressure. Cavitation can damage the pump and reduce its performance.

9. How do you troubleshoot a pump that is not working properly?

- Check the power supply to the pump.

- Check the pump for leaks.

- Check the impeller for damage.

- Check the bearings for wear.

- Check the seals for leaks.

10. What is your experience with pumps?

- I have worked with pumps for over 10 years. I have experience with a variety of pumps, including centrifugal pumps, positive displacement pumps, and submersible pumps. I have also experience with troubleshooting and repairing pumps.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pumper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pumper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pumpers are responsible for operating and maintaining pumping systems, such as those used in oil and gas production, water treatment, and sewage treatment. They must have a strong understanding of the equipment they are working with, as well as the procedures for operating and maintaining it. Pumpers also need to be able to troubleshoot and repair problems that may arise.

1. Operate pumping systems

Pumpers are responsible for operating pumping systems that move fluids from one location to another. They must be able to start, stop, and adjust the speed and flow of the pumps.

- Start, stop, and adjust the speed and flow of pumps

- Monitor the operation of pumps and make adjustments as needed

2. Maintain pumping systems

Pumpers are also responsible for maintaining pumping systems. This includes inspecting the equipment, lubricating it, and making repairs as needed.

- Inspect pumps and other equipment for wear and tear

- Lubricate pumps and other equipment

- Make repairs to pumps and other equipment

3. Troubleshoot and repair problems

Pumpers must be able to troubleshoot and repair problems that may arise with pumping systems. This may involve identifying the problem, determining the cause, and making the necessary repairs.

- Identify problems with pumping systems

- Determine the cause of problems

- Make repairs to pumping systems

4. Follow safety procedures

Pumpers must always follow safety procedures when working with pumping systems. This includes wearing appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Wear appropriate safety gear

- Follow lockout/tagout procedures

- Be aware of potential hazards

Interview Tips

Preparing for a job interview is important, and there are a few tips that can help you ace the interview for a pumper position.

1. Research the company

Before you go to the interview, take some time to research the company. This will help you understand their business, their culture, and the specific role you are applying for. You can find information about the company on their website, in their annual report, and in news articles.

- Visit the company’s website

- Read the company’s annual report

- Search for news articles about the company

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?” It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and clearly.

- Tell me about yourself

- Why are you interested in this job?

- What are your strengths and weaknesses?

3. Be prepared to talk about your experience

The interviewer will want to know about your experience working with pumping systems. Be prepared to talk about your experience in detail, including the specific tasks you performed and the equipment you worked with.

- Talk about your experience operating pumping systems

- Talk about your experience maintaining pumping systems

- Talk about your experience troubleshooting and repairing pumping systems

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic about the job and who is positive about their ability to do the work. Be sure to show your enthusiasm and positivity during the interview.

- Be enthusiastic about the job

- Be positive about your ability to do the work

- Be confident in your answers

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pumper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.