Are you gearing up for a career in Punch and Assembly Department Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Punch and Assembly Department Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

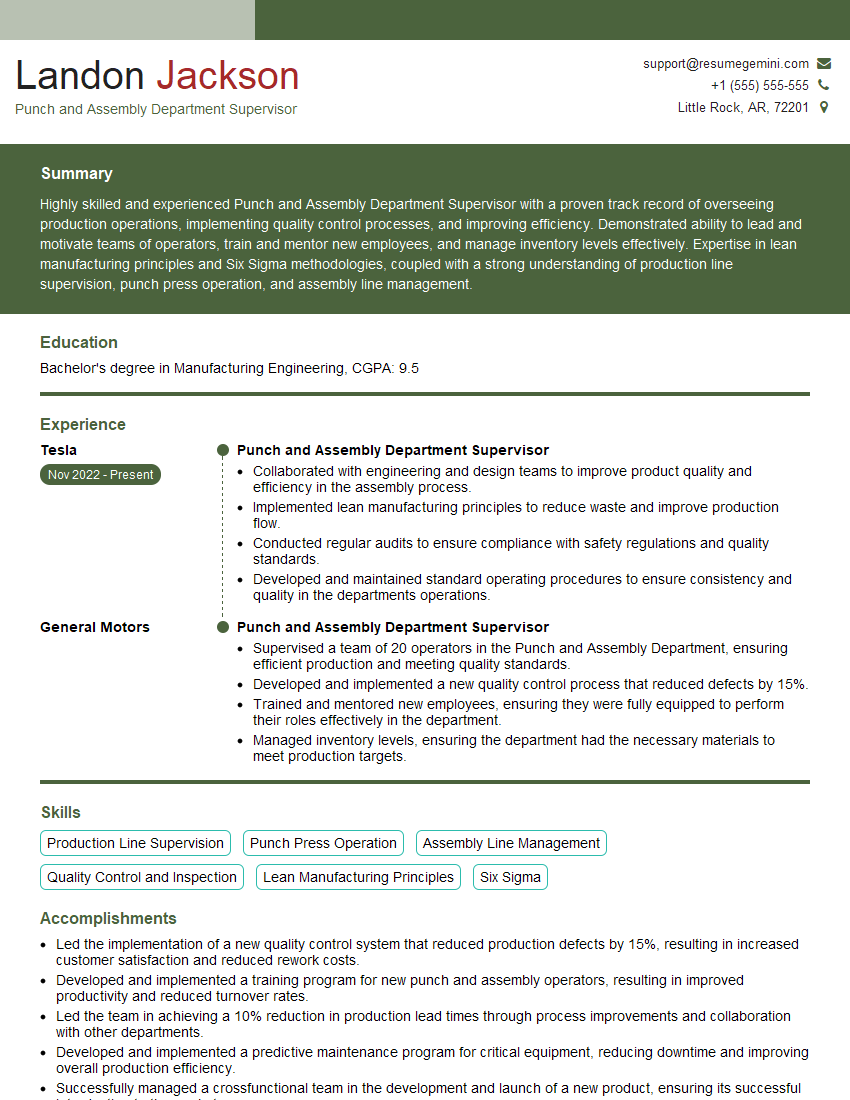

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Punch and Assembly Department Supervisor

1. What is the difference between a punch and a die?

- A punch is a tool that is used to cut or form metal. It is typically made of hardened steel and has a sharp edge.

- A die is a tool that is used to form metal. It is typically made of hardened steel and has a cavity that is the same shape as the desired part.

2. What are the different types of punches and dies?

There are many different types of punches and dies, each designed for a specific purpose. Some of the most common types of punches include:

Types of Punches

- Round punches

- Square punches

- Rectangle punches

- Oval punches

- Hexagonal punches

Some of the most common types of dies include:

Types of Dies

- Blanking dies

- Piercing dies

- Forming dies

- Compound dies

- Progressive dies

3. What are the factors that affect the quality of a punched or stamped part?

- The type of punch and die

- The condition of the punch and die

- The material being punched or stamped

- The thickness of the material

- The speed of the punching or stamping operation

4. What are the safety precautions that should be taken when operating a punch press?

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Inspect the punch press and dies before each use.

- Never put your hands or fingers in the die area.

- Keep the punch press area clean and free of debris.

- Follow all manufacturer’s instructions for operating the punch press.

5. What is the assembly process for the product?

- Step 1: Gather all of the necessary parts and materials.

- Step 2: Prepare the parts for assembly by cleaning and deburring them.

- Step 3: Assemble the parts according to the assembly drawing.

- Step 4: Inspect the assembled product to ensure that it meets all of the specifications.

- Step 5: Package the product for shipping.

6. What are the quality control measures that are in place to ensure that the assembly process is producing high-quality products?

- All parts are inspected before they are assembled.

- The assembly process is monitored to ensure that it is being followed correctly.

- The finished products are inspected to ensure that they meet all of the specifications.

- Regular audits are conducted to ensure that the quality control system is effective.

7. What are the safety precautions that should be taken when working in an assembly department?

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Be aware of the location of emergency exits and fire extinguishers.

- Follow all manufacturer’s instructions for operating assembly equipment.

- Never put your hands or fingers in the moving parts of assembly equipment.

8. What are the key performance indicators (KPIs) that you use to measure the performance of the punch and assembly department?

- Output per hour

- Scrap rate

- Rework rate

- Customer satisfaction

- Employee safety

9. What are your goals for improving the performance of the punch and assembly department?

- Increase output per hour

- Reduce scrap rate

- Reduce rework rate

- Improve customer satisfaction

- Improve employee safety

10. What are your strengths and weaknesses as a punch and assembly department supervisor?

Strengths:

- Strong technical knowledge of punch and assembly equipment

- Excellent problem-solving skills

- Proven ability to lead and motivate a team

- Strong commitment to safety

Weaknesses:

- Sometimes I can be too detail-oriented

- I can be impatient at times

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Punch and Assembly Department Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Punch and Assembly Department Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Punch and Assembly Department Supervisor is a critical role in ensuring the smooth and efficient functioning of the punch and assembly department.

1. Planning and Scheduling Work

Develops and implements production schedules for the department, taking into account customer orders, lead times, and resource availability

- Monitors progress and makes adjustments as needed

- Coordinates with other departments, such as procurement and maintenance

2. Supervising and Developing Team

Leads and motivates a team of punch press operators and assemblers

- Provides training and support

- Conducts performance evaluations and provides feedback

3. Maintaining Quality and Efficiency

Ensures the production of high-quality parts and assemblies

- Develops and implements quality control procedures

- Monitors production processes and identifies areas for improvement

4. Managing Inventory and Equipment

Maintains inventory of raw materials and finished goods

- Ensures that equipment is properly maintained and calibrated

- Orders new equipment and supplies as needed

5. Safety and Compliance

Ensures that the department complies with all safety regulations

- Conducts safety inspections and training

- Investigates and reports accidents and incidents

Interview Tips

Preparing for an interview for the Punch and Assembly Department Supervisor position requires research, practice, and confidence.

1. Research Company and Industry

Learn about the company’s history, products, and market position.

- Understand the industry trends and challenges

2. Know your Resume Inside Out

Be able to discuss your experience and skills in detail and relate them to the job requirements.

- Practice answering common interview questions

3. Prepare Questions for the Interviewer

Ask insightful questions that demonstrate your interest in the position and the company.

- This shows that you are engaged and eager to learn more

4. Dress Appropriately and Arrive on Time

First impressions matter in an interview.

- Dress professionally and arrive for your interview on time

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Punch and Assembly Department Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.