Are you gearing up for a career in Punch Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Punch Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

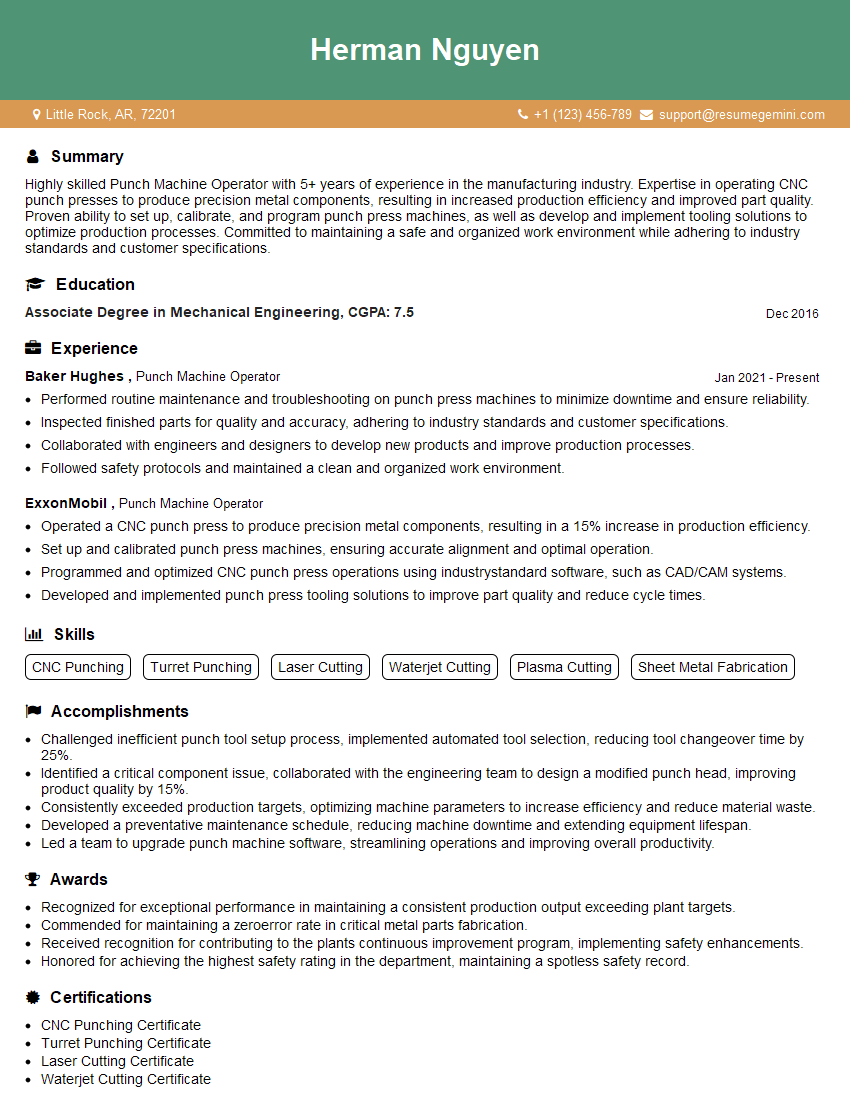

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Punch Machine Operator

1. Explain the steps involved in setting up a punch machine?

To set up a punch machine, I follow these steps:

- Inspect and clean the machine.

- Load the workpiece and secure it in place.

- Select the appropriate punch and die set.

- Adjust the machine settings, including pressure, speed, and stroke length.

- Test the machine to ensure it is operating correctly.

2. Describe the different types of punch machines and their applications?

- Mechanical punch machines: These machines use a mechanical drive to power the punch. They are typically used for low-volume production and simple punching operations.

- Hydraulic punch machines: These machines use hydraulic pressure to power the punch. They are more powerful than mechanical machines and can be used for a wider range of punching operations.

- Pneumatic punch machines: These machines use compressed air to power the punch. They are lightweight and portable, making them suitable for use in a variety of applications.

- CNC punch machines: These machines are computer-controlled and can be programmed to perform complex punching operations. They are used for high-volume production and precision punching.

3. What are the safety precautions that should be taken when operating a punch machine?

- Wear appropriate safety gear, including eye protection, gloves, and hearing protection.

- Keep hands out of the punching area.

- Never operate the machine when it is not fully guarded.

- Be aware of the location of the emergency stop button.

- Follow all manufacturer’s instructions for safe operation.

4. How do you troubleshoot common punch machine problems?

Here are some common punch machine problems and their troubleshooting steps:

- Machine not punching properly: Check the punch and die set for damage or wear. Adjust the machine settings as needed.

- Workpiece not being held securely: Check the clamps and make sure they are tightened properly.

- Machine making excessive noise: Check the machine for loose parts or worn bearings. Lubricate the machine as needed.

- Machine overheating: Check the hydraulic fluid level and make sure the machine is properly ventilated.

5. What are the different types of punches and dies used in punch machines?

- Round punches: Used for punching holes in thin materials.

- Square punches: Used for punching square holes in materials.

- Oblong punches: Used for punching oblong holes in materials.

- Die buttons: Used to support the workpiece and prevent it from being damaged by the punch.

- Stripper plates: Used to remove the workpiece from the punch after it has been punched.

6. Describe the process of precision punching?

- Prepare the workpiece by cleaning and deburring the edges.

- Select the appropriate punch and die set.

- Adjust the machine settings to ensure accurate positioning of the punch and die.

- Punch the workpiece slowly and carefully.

- Inspect the punched workpiece for accuracy and quality.

7. What is the difference between a punch and a die?

A punch is the male part of the punching tool that penetrates the workpiece. A die is the female part of the punching tool that supports the workpiece and provides the shape of the punched hole.

8. What are the different types of materials that can be punched using a punch machine?

Punch machines can be used to punch a variety of materials, including:

- Metals (e.g., steel, aluminum, brass)

- Plastics

- Paper

- Rubber

- Leather

9. What are the advantages of using a punch machine?

- High precision and accuracy

- Fast production rates

- Ability to punch complex shapes

- Low operating costs

10. What is the difference between a punch press and a laser cutter?

A punch press uses a punch and die to cut material, while a laser cutter uses a laser beam to cut material. Punch presses are generally more affordable and faster than laser cutters, but laser cutters can produce more precise and complex cuts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Punch Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Punch Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Punch Machine Operators play a crucial role in various industries, including manufacturing and metalworking. Their primary responsibilities involve operating punch machines to create holes, shapes, and designs in various materials.

1. Machine Operation and Setup

Punch Machine Operators are responsible for setting up and operating punch machines following specific instructions and blueprints. They ensure that the machines are properly calibrated and adjusted to produce precise cuts and shapes.

- Positioning and securing materials on the machine table

- Programming the machine with the required cutting patterns and dimensions

- Monitoring the machine’s operation and making adjustments as needed

2. Quality Control

Ensuring the quality of the punched parts is a critical aspect of the job. Operators inspect the punched pieces for accuracy, dimensions, and any defects. They compare the parts with the specifications and make adjustments to the machine or tooling to maintain quality standards.

- Inspecting punched parts for precision and conformity

- Identifying and correcting any deviations from the specifications

- Maintaining a clean and organized work area to minimize errors

3. Troubleshooting and Maintenance

Punch Machine Operators often encounter technical issues and malfunctions during their work. They are expected to troubleshoot and resolve common problems to keep the machine running smoothly. They also perform routine maintenance tasks, such as lubrication and cleaning, to ensure the machine’s longevity.

- Diagnosing and repairing minor machine issues

- Performing preventive maintenance and cleaning procedures

- Reporting any major problems or malfunctions to supervisors

4. Safety and Compliance

Punch machines can be dangerous if not operated correctly. Operators are responsible for adhering to safety regulations and wearing appropriate personal protective equipment (PPE) to minimize the risk of accidents. They also ensure that the machine is operated in a safe and compliant manner.

- Following safety protocols and wearing PPE

- Maintaining a safe and clean work environment

- Complying with all applicable regulations and standards

Interview Tips

Preparing thoroughly for a Punch Machine Operator interview can significantly increase your chances of success. Here are some tips and hacks to help you ace the interview:

1. Research the Company and the Role

Take time to research the company and the specific role you are applying for. This will give you a good understanding of their business, industry, and the requirements of the job. Knowing the company’s goals, values, and products will help you tailor your answers to the interviewer’s questions.

- Visit the company’s website to learn about their history, products, and services.

- Read industry-related news and articles to stay updated on the latest trends and technologies.

- Practice answering common interview questions related to your skills, experience, and why you are interested in the role.

2. Highlight Your Technical Skills and Experience

Emphasize your technical skills and previous experience in operating punch machines. Quantify your accomplishments whenever possible to demonstrate your abilities. If you have operated different types of punch machines, mention your familiarity with their capabilities and limitations.

- Describe your experience in setting up, programming, and operating punch machines.

- Provide examples of how you have used your skills to improve efficiency or reduce waste.

- Mention any certifications or training you have received in punch machine operation.

3. Showcase Your Problem-Solving Abilities

Interviewers want to know that you can think critically and solve problems independently. Highlight your ability to troubleshoot common machine issues and make adjustments to maintain production. Share examples of how you have identified and resolved problems in the past.

- Describe a situation where you encountered a machine malfunction and how you diagnosed and fixed it.

- Explain how you would approach a problem that you have not encountered before.

- Share your knowledge of preventive maintenance techniques and how you have used them to ensure the longevity of punch machines.

4. Emphasize Your Safety Consciousness

Safety is paramount in any industrial environment. Emphasize your understanding of the importance of following safety protocols and wearing appropriate PPE. Explain how you have maintained a safe work environment and prevented accidents in previous roles.

- Describe your knowledge of safety regulations and how you have implemented them in your work.

- Provide examples of how you have identified and eliminated potential hazards in the workplace.

- Explain how you stay updated on the latest safety standards and best practices.

5. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare several questions related to the role, the company, and the industry. This not only demonstrates your curiosity but also allows you to gain valuable insights.

- Ask about the company’s growth plans and how this role contributes to those plans.

- Inquire about the company’s commitment to safety and how it is implemented in the workplace.

- Ask about opportunities for professional development and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Punch Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!