Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Punch Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

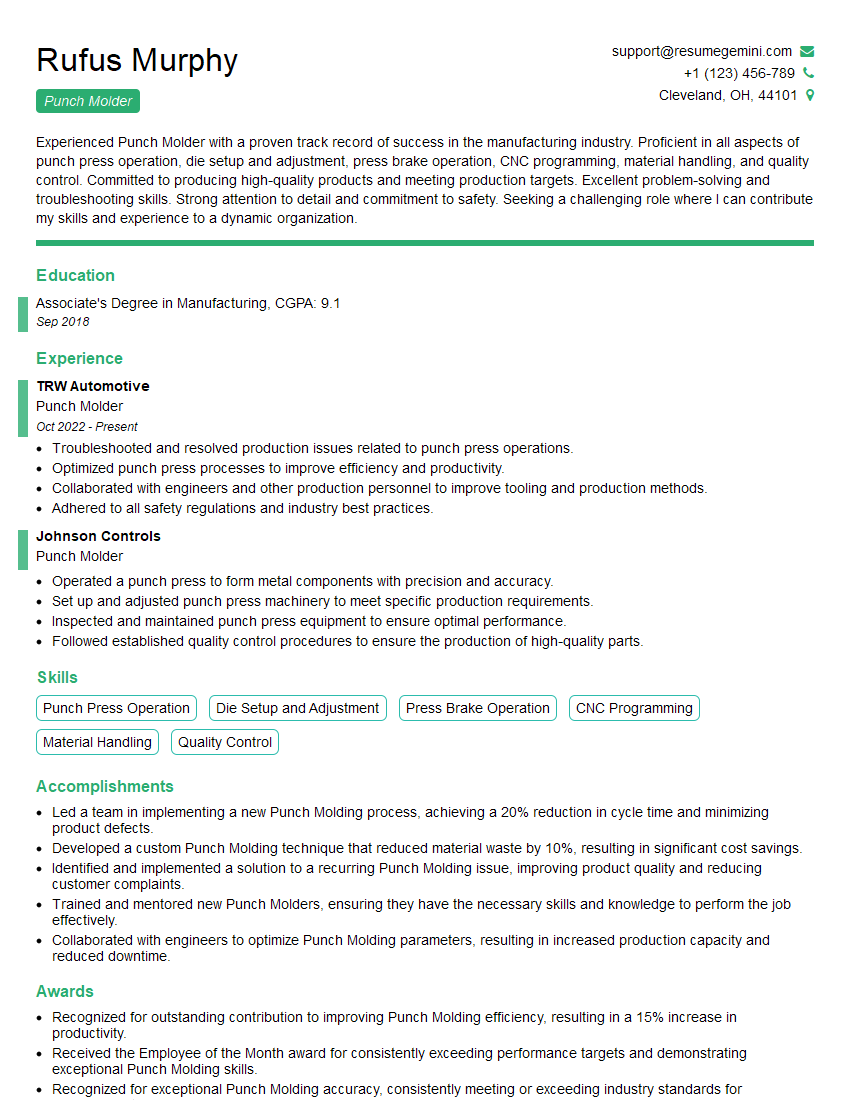

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Punch Molder

1. What are the key responsibilities of a Punch Molder?

The key responsibilities of a Punch Molder include:

- Set up and operate punch molding machines

- Inspect and maintain punch molding equipment

- Ensure that products meet quality standards

- Work with other team members to achieve production goals

2. What are the different types of punch molding machines?

Injection Molding Machines

- Used to mold thermoplastic materials

- Material is injected into a heated mold

- Mold is cooled and opened to release the molded product

Compression Molding Machines

- Used to mold thermosetting materials

- Material is placed in a heated mold

- Mold is closed and pressure is applied to form the product

Transfer Molding Machines

- Similar to injection molding machines

- Material is first transferred to a secondary chamber

- Material is then injected into the mold

3. What are the different types of punch molding materials?

- Thermoplastics (e.g., polyethylene, polypropylene, PVC)

- Thermosets (e.g., epoxy, polyester, phenolic)

- Elastomers (e.g., natural rubber, synthetic rubber)

4. What are the key factors to consider when selecting a punch molding material?

- End use of the product

- Mechanical properties (e.g., strength, flexibility, hardness)

- Thermal properties (e.g., melting point, glass transition temperature)

- Cost

5. What are the different types of punch molding defects?

- Flash (excess material that escapes from the mold)

- Sink marks (depressions in the product caused by shrinkage)

- Voids (empty spaces in the product caused by trapped air)

- Cracks (fractures in the product caused by stress)

6. How do you prevent punch molding defects?

- Proper mold design and maintenance

- Correct selection of molding material

- Proper molding process parameters

- Quality control and inspection

7. What are the different methods of decorating punch molded products?

- Painting

- Plating

- Vacuum metallizing

- In-mold decoration

8. What are the different applications of punch molded products?

- Automotive parts

- Electronic components

- Medical devices

- Toys and games

- Consumer products

9. What are the latest trends in punch molding technology?

- Advanced mold design and simulation software

- New materials with improved properties

- Automated molding processes

- Environmental sustainability initiatives

10. What are the challenges facing the punch molding industry?

- Competition from other manufacturing processes

- Rising costs of raw materials and energy

- Increasing demand for customized products

- Environmental regulations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Punch Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Punch Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Punch Molders are accountable for operating, maintaining, and repairing punch molding machines used in the production of plastic and rubber products. They ensure that machines are running efficiently and producing quality products while adhering to safety regulations.

1. Machine Operation

Primary responsibility involves operating punch molding machines. This entails:

- Setting up and calibrating machines according to production specifications.

- Loading raw materials into the machine and initiating the molding process.

- Monitoring machine performance and making necessary adjustments to optimize production.

2. Quality Control

Punch Molders play a crucial role in quality control by:

- Inspecting molded products for defects and ensuring they meet quality standards.

- Identifying and addressing any issues that could impact product quality.

- Maintaining detailed records of production data and quality control checks.

3. Machine Maintenance

Punch Molders are responsible for maintaining and repairing punch molding machines. This includes:

- Performing routine maintenance tasks such as cleaning, lubricating, and adjusting machines.

- Troubleshooting and repairing minor machine malfunctions.

- Coordinating with maintenance personnel for major repairs or overhauls.

4. Safety Compliance

Punch Molders must comply with safety regulations and protocols. They are expected to:

- Wear appropriate personal protective equipment.

- Follow established safety procedures and guidelines.

- Report any safety hazards or concerns immediately.

Interview Tips

Preparing thoroughly for an interview is critical for success. Here are some tips to help you ace your Punch Molder interview:

1. Research the Company and Role

Before the interview, take the time to research the company and the specific Punch Molder role. This will demonstrate your interest in the position and the organization. Familiarize yourself with the company’s products, services, and industry standing.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job responsibilities. Quantify your accomplishments and provide specific examples that demonstrate your abilities in machine operation, quality control, maintenance, and safety compliance.

3. Prepare for Technical Questions

Expect technical questions during the interview. Practice answering questions related to the punch molding process, machine setup and calibration, quality control techniques, and basic machine troubleshooting.

4. Showcase Safety Awareness

Punch Molding involves potential safety hazards. Emphasize your commitment to safety and your knowledge of safety regulations and procedures. Share examples of your experience in identifying and mitigating safety risks.

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest in the position and the company. This could include questions about the company’s growth plans, the importance of quality control, or the opportunities for professional development.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Punch Molder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Punch Molder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.