Are you gearing up for a career in Punch Press Setter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Punch Press Setter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

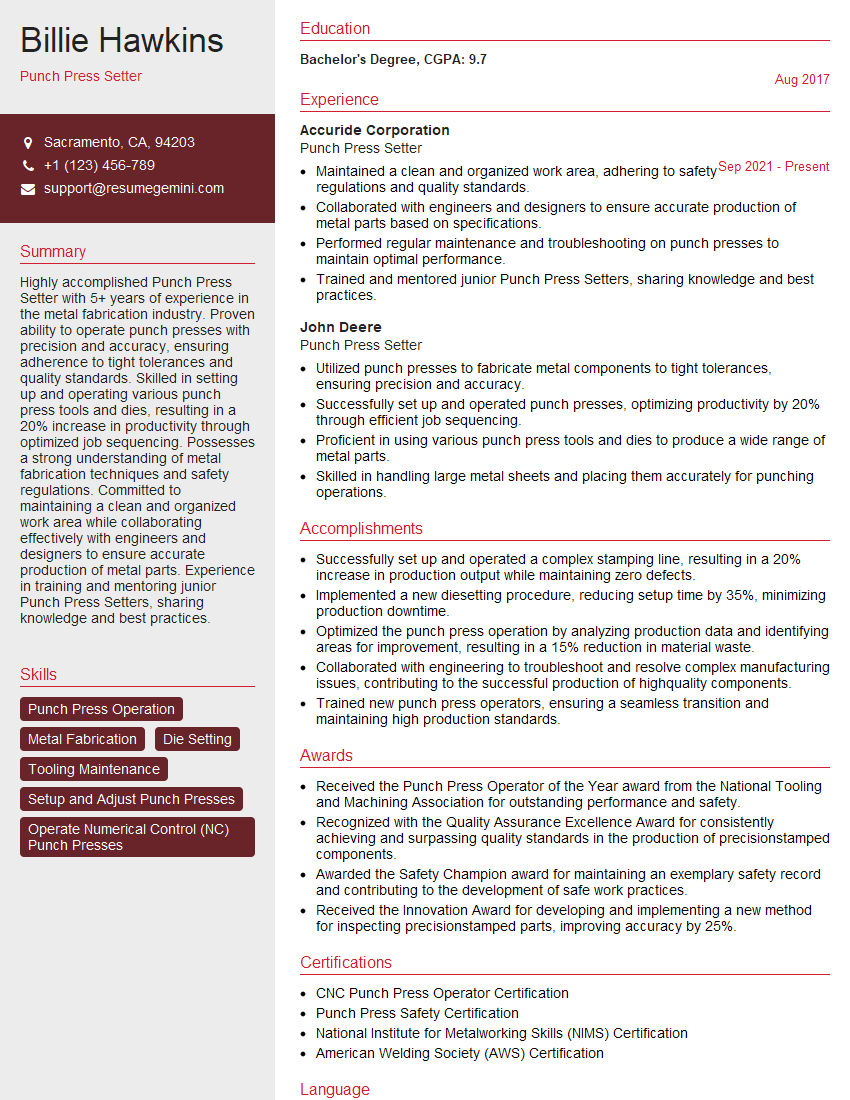

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Punch Press Setter

1. What are the different types of punch presses and their applications?

There are various types of punch presses, each designed for specific applications:

- Mechanical Punch Presses: These presses utilize a flywheel and clutch mechanism to deliver high force and are commonly used for stamping, piercing, and shearing operations.

- Hydraulic Punch Presses: Hydraulic presses use pressurized oil to generate force, offering precise control and quieter operation. They are ideal for blanking, forming, and deep drawing.

- Pneumatic Punch Presses: Air-powered, these presses are often used for light-duty applications such as punching holes or embossing. They are known for their speed and ease of operation.

- Turret Punch Presses: These presses feature multiple stations that can perform various operations, including punching, forming, and tapping. They are suitable for high-volume production.

- Laser Punch Presses: Equipped with a laser beam, these presses offer precise cutting and etching capabilities. They are commonly used in industries such as electronics and medical device manufacturing.

2. Describe the process of setting up and operating a punch press safely.

Pre-Setup:

- Read and understand the machine manual and safety protocols.

- Inspect the press, dies, and tools for any damage or wear.

- Clear the work area and ensure proper lighting.

Setup:

- Install and align the dies and tools securely.

- Set the press parameters, including speed, force, and stroke length.

- Place the material to be punched on the die table.

Operation:

- Wear appropriate safety gear, including eye protection and gloves.

- Start the press and monitor the operation closely.

- Stop the press immediately if any unusual noises or vibrations occur.

Post-Operation:

- Unclamp the material and remove the punched parts.

- Clean and lubricate the machine.

- Report any issues or maintenance needs to the supervisor.

3. How do you maintain and troubleshoot punch press equipment?

Punch press maintenance and troubleshooting involve the following steps:

- Regular Inspection: Inspect the press, dies, and tools for wear, damage, or misalignment. Tighten loose connections and replace worn parts.

- Lubrication: Lubricate all moving parts as per the manufacturer’s recommendations to reduce friction and prevent excessive wear.

- Calibration: Calibrate the press regularly to ensure accurate and consistent operation.

Troubleshooting:

- Unusual Noises: Check for loose components or damaged bearings.

- Excessive Vibration: Inspect the dies for misalignment or wear.

- Poor Punch Quality: Sharpen or replace dull punches, ensure correct die clearance, or adjust press settings.

- Machine Malfunctions: Consult the machine manual or seek assistance from a qualified technician.

4. What are the different types of punches and dies used in punch presses?

Punch press punches and dies come in a wide variety:

Punches:

- Solid Punches: Used for general-purpose punching.

- Compound Punches: Feature multiple cutting edges for complex shapes.

- Subland Punches: Provide a clearance hole for waste material.

- Explosive Punches: Produce high-force impact for cutting hard materials.

Dies:

- Cut-Off Dies: Used for shearing materials into specific lengths.

- Piercing Dies: Create holes in the material.

- Blanking Dies: Cut out specific shapes from the material.

- Forming Dies: Bend or shape the material into desired contours.

- Progressive Dies: Perform multiple operations in a single stroke.

5. How do you determine the correct die clearance for a specific material and application?

Determining die clearance involves the following steps:

- Material Thickness: Thicker materials require larger clearances.

- Material Hardness: Harder materials need smaller clearances.

- Punch Diameter: Larger punches require larger clearances.

- Application: Different applications may require specific clearances for optimal results (e.g., shearing, piercing, forming).

General guidelines suggest a die clearance of 5% to 10% of the material thickness for shearing and 1% to 5% for piercing.

6. What is the purpose of using a stripper plate in a punch press?

- Prevents Material Scrap: Stripper plates keep the material flat and prevent it from being dragged into the die, reducing scrap.

- Improves Punch Life: By preventing material from wrapping around the punch, stripper plates extend its lifespan.

- Enhances Cutting Accuracy: Stripper plates help maintain the correct material position, improving cutting precision.

7. Describe the importance of die alignment in punch press operation.

- Accurate Punching: Proper die alignment ensures that the punch and die are precisely positioned relative to each other, resulting in clean and accurate cuts.

- Reduced Die Wear: Misaligned dies can cause excessive wear on the cutting edges, reducing their lifespan.

- Improved Safety: Proper alignment minimizes the risk of material jamming or tool breakage, enhancing safety during operation.

8. What are the key safety precautions to follow when working with punch presses?

- Wear Proper Safety Gear: This includes eye protection, earplugs, gloves, and appropriate clothing.

- Clear the Work Area: Ensure there are no loose materials or obstructions around the press.

- Never Reach Over the Die: Keep hands away from the cutting area.

- Use a Safety Block: Always secure material with a safety block or clamp.

- Avoid Hand Feeding: Use a feed mechanism or automated system to load materials.

- Regular Maintenance: Inspect the press and dies regularly to ensure proper operation.

9. How do you calculate the force required for a given punching operation?

The force required for punching can be calculated using the following formula:

Force = Shear Strength of Material x Material Thickness x Perimeter of Cut

10. What are the different methods used to lubricate punch press equipment?

- Manual Lubrication: Using an oil can or grease gun to apply lubricant to specific points.

- Centralized Lubrication System: A system that automatically delivers lubricant to multiple points from a central reservoir.

- Mist Lubrication: A fine mist of oil is sprayed onto moving parts to reduce friction.

- Semi-Automated Lubrication: A combination of manual and automated lubrication methods.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Punch Press Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Punch Press Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Punch Press Setter plays a pivotal role in manufacturing processes, operating and maintaining punch presses to produce high-volume metal components.

1. Machine Operation and Maintenance

• Accurately set up and operate punch presses to produce metal parts according to specifications.

- Select and install appropriate dies and tooling.

- Adjust machine settings, including pressure, speed, and feed rates.

- Monitor production processes and make adjustments as needed to ensure quality and efficiency.

- Perform routine inspections and maintenance on machines, including lubrication, cleaning, and minor repairs.

2. Production Monitoring and Quality Control

• Ensure that produced parts meet specified quality standards through regular inspections.

- Conduct dimensional and visual checks using measuring instruments and gauges.

- Identify defects and take corrective actions to minimize scrap and rework.

- Maintain production records and report any quality issues to supervisors.

3. Material Handling and Inventory Management

• Handle and transport materials and products safely and efficiently.

- Load and unload raw materials, dies, and finished parts from machines.

- Maintain inventory of materials and tools, and request replenishment as needed.

- Manage scrap and waste materials to maintain a clean and organized work area.

4. Safety Compliance and Training

• Adhere to all safety regulations and wear appropriate protective gear.

- Follow established safety protocols and procedures.

- Participate in safety training programs and stay informed about safety best practices.

- Report any safety hazards or incidents to supervisors and assist in maintaining a safe work environment.

Interview Tips

Thorough preparation can increase your chances of success in a Punch Press Setter interview. Here are some key tips to help you ace it:

1. Research the Company and Position

• Familiarize yourself with the company’s products, services, and industry.

- Visit the company website, read company profiles, and check social media pages.

- Review the job description thoroughly to understand the roles and responsibilities.

2. Highlight Relevant Experience and Skills

• Emphasize your experience operating punch presses and producing metal components.

- Showcase your knowledge of different types of dies and their applications.

- Describe your experience in maintaining and troubleshooting punch presses.

- Provide specific examples of how you have improved production efficiency or quality.

3. Demonstrate Safety Awareness and Compliance

• Emphasize your commitment to safety and your understanding of safety regulations.

- Explain how you ensure compliance with safety procedures and maintain a safe work environment.

- Highlight any safety training or certifications you have acquired.

4. Prepare for Technical Questions

• Anticipate questions about punch press operation, maintenance, and troubleshooting.

- Review common punch press terminology and calculations.

- Consider preparing examples of technical problems you have solved or challenges you have overcome.

5. Ask Informed Questions

• Show your interest and engagement by asking thoughtful questions about the company, the position, or the industry.

- Inquire about the company’s growth plans or current industry trends.

- Ask about specific technologies or processes used in the organization.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Punch Press Setter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Punch Press Setter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.