Are you gearing up for an interview for a Punchboard Filling Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Punchboard Filling Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

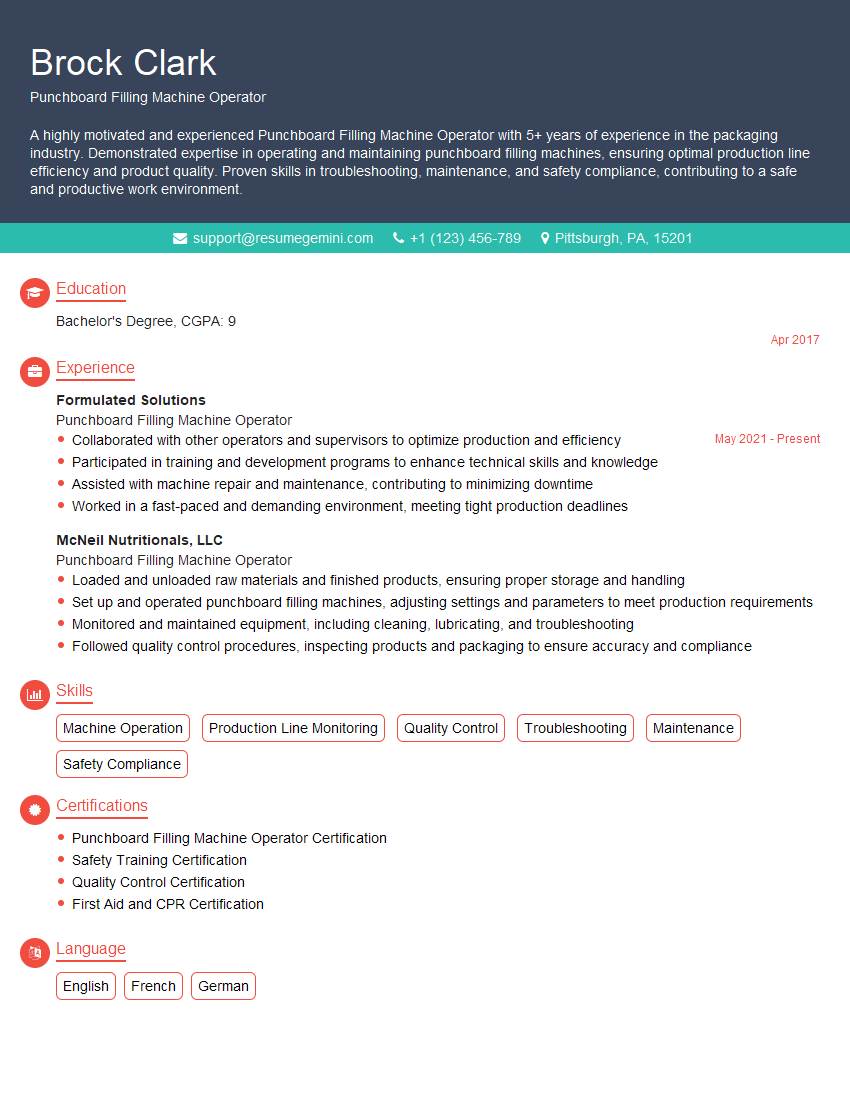

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Punchboard Filling Machine Operator

1. What are the basic principles of punchboard filling machine operation?

– In-depth knowledge of the principles of punchboard filling system. – Understanding of the mechanical, electrical, and hydraulic systems of the machine. – Understanding of the process of how the machine fills punchboards.

2. How do you troubleshoot punchboard filling machine malfunctions?

Troubleshooting electrical issues

- Inspect electrical connections and wiring for damage or loose connections.

- Check fuses and circuit breakers for any blown or tripped components.

- Use a multimeter to test electrical components for continuity and proper voltage.

Troubleshooting mechanical issues

- Inspect moving parts for any wear, damage, or misalignment.

- Check for any obstructions or blockages in the machine’s path.

- Listen for any unusual noises or vibrations that may indicate a mechanical fault.

Troubleshooting hydraulic issues

- Check hydraulic fluid levels and condition.

- Inspect hydraulic hoses and fittings for any leaks or damage.

- Test hydraulic pressure using a pressure gauge.

3. What are the safety precautions that need to be followed when operating a punchboard filling machine?

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Follow lockout/tagout procedures to prevent accidental machine startup during maintenance or troubleshooting.

- Keep the work area clean and free from tripping hazards.

- Be aware ofpinch points and moving parts and keep hands and clothing away from them.

- Never override safety devices or attempt to operate the machine with known malfunctions.

4. How do you maintain a punchboard filling machine?

- Regularly clean and lubricate all moving parts.

- Inspect the machine for any signs of wear or damage.

- Check and adjust fluid levels as needed.

- Calibrate the machine according to the manufacturer’s specifications.

- Keep a maintenance log to track all maintenance activities and identify any recurring issues.

5. What are the different types of punchboard filling machines and their applications?

- Rotary punchboard filling machines: These machines are used for high-volume filling of punchboards. They have a rotating turret that holds the punchboards and a set of filling heads that fill the holes in the punchboards.

- Inline punchboard filling machines: These machines are used for lower-volume filling of punchboards. They have a conveyor that transports the punchboards through the filling process.

- Semi-automatic punchboard filling machines: These machines require an operator to manually load and unload the punchboards. They are typically used for small-scale or intermittent filling operations.

6. What is the role of the punchboard filling machine operator?

- Operate the punchboard filling machine to fill punchboards with various products.

- Monitor the machine’s performance and make adjustments as needed.

- Troubleshoot and resolve any malfunctions that occur.

- Maintain the machine according to the manufacturer’s specifications.

- Ensure that the punchboards are filled to the correct weight or volume.

7. What are the qualities of a successful punchboard filling machine operator?

- Strong mechanical and electrical troubleshooting skills.

- Knowledge of punchboard filling machine principles and operation.

- Ability to work independently and as part of a team.

- Excellent communication and interpersonal skills.

- Ability to work in a fast-paced and demanding environment.

8. What is your experience with different types of punchboard filling machines?

– Experience with various types of punchboard filling machines, including rotary, inline, and semi-automatic machines. – Knowledge of the specific features and capabilities of each type of machine. – Understanding of the different applications and industries where each type of machine is used.

9. Can you describe a time when you successfully resolved a complex issue with a punchboard filling machine?

- Describe the specific issue that occurred.

- Explain the steps taken to troubleshoot and diagnose the problem.

- Describe the solution implemented and the outcome.

- Highlight any specific skills or knowledge that were utilized.

10. How do you stay up-to-date with the latest advancements in punchboard filling technology?

- Attend industry conferences and trade shows.

- Read technical publications and articles.

- Participate in online forums and discussions.

- Consult with equipment manufacturers and suppliers.

- Take advantage of training opportunities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Punchboard Filling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Punchboard Filling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Punchboard Filling Machine Operator is responsible for operating and maintaining punchboard filling machines. These machines are used to fill punchboards with a variety of items, such as candy, gum, and small toys. The operator’s key responsibilities include:

1. Operating the punchboard filling machine

The operator must be able to properly set up and operate the punchboard filling machine. This includes loading the machine with punchboards, setting the machine’s speed and pressure settings, and starting and stopping the machine.

- Loading the machine with punchboards

- Setting the machine’s speed and pressure settings

- Starting and stopping the machine

2. Monitoring the punchboard filling machine

The operator must closely monitor the punchboard filling machine while it is running. This includes watching the machine for any signs of trouble, such as jams or leaks.

- Watching the machine for any signs of trouble

- Taking corrective action if any problems occur

3. Maintaining the punchboard filling machine

The operator is responsible for maintaining the punchboard filling machine. This includes cleaning the machine, lubricating the moving parts, and making minor repairs.

- Cleaning the machine

- Lubricating the moving parts

- Making minor repairs

4. Troubleshooting the punchboard filling machine

The operator must be able to troubleshoot the punchboard filling machine if it breaks down. This includes diagnosing the problem, making repairs, and getting the machine back up and running.

- Diagnosing the problem

- Making repairs

- Getting the machine back up and running

Interview Tips

To prepare for an interview for a Punchboard Filling Machine Operator position, you should:

1. Research the company and the position

This will help you understand the company’s culture and the specific requirements of the job.

- Read the company’s website and social media pages.

- Look for news articles and other information about the company.

- Identify the key skills and experience required for the position.

2. Practice answering common interview questions

This will help you feel more confident and prepared during the interview. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Can you describe your experience operating and maintaining punchboard filling machines?

3. Be prepared to talk about your experience

The interviewer will want to know about your experience operating and maintaining punchboard filling machines. Be sure to highlight your skills and experience in your resume and cover letter.

- Describe your experience operating and maintaining punchboard filling machines.

- Highlight your skills and experience in your resume and cover letter.

4. Be prepared to ask questions

Asking questions at the end of the interview shows that you are interested in the position and the company. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the company’s growth plans for the future?

- What is the company culture like?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Punchboard Filling Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.