Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Push Connector Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

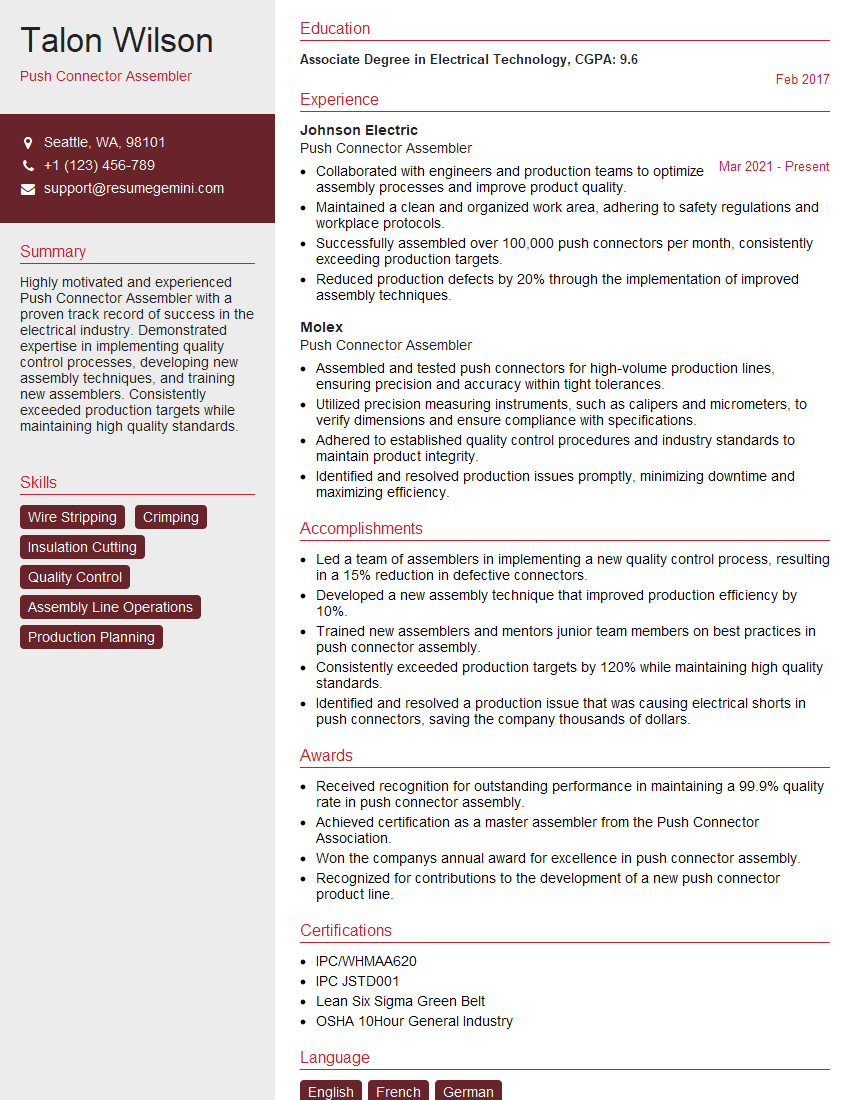

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Push Connector Assembler

1. What is the process of assembling push connectors?

The process of assembling push connectors typically involves the following steps:

- Inspect the connector components for any defects.

- Prepare the wires by stripping the insulation to the specified length.

- Insert the wires into the appropriate terminals of the connector.

- Use a crimping tool to secure the wires in place.

- Inspect the finished assembly for any defects.

2. What are the different types of push connectors?

Waterproof connectors

- These connectors are designed to resist moisture and are often used in outdoor applications.

Insulated connectors

- These connectors are covered with an insulating material to prevent electrical shock.

Non-insulated connectors

- These connectors are not covered with an insulating material and are typically used in low-voltage applications.

3. What are the advantages of using push connectors?

Some of the advantages of using push connectors include:

- They are easy to use and do not require any special tools.

- They are relatively inexpensive.

- They provide a secure connection.

- They are available in a variety of sizes and types.

4. What are the disadvantages of using push connectors?

Some of the disadvantages of using push connectors include:

- They may not be as durable as other types of connectors.

- They may not be suitable for use in high-voltage applications.

5. What are the safety precautions that should be taken when working with push connectors?

When working with push connectors, it is important to take the following safety precautions:

- Always wear appropriate safety gear, such as safety glasses and gloves.

- Do not work on live circuits.

- Use the correct tools for the job.

- Inspect the connectors before using them.

- Follow the manufacturer’s instructions for use.

6. What is the difference between a push connector and a crimp connector?

Push connectors and crimp connectors are both used to connect wires, but they do so in different ways. Push connectors use a spring-loaded mechanism to hold the wires in place, while crimp connectors use a crimping tool to compress the connector around the wires.

7. What is the proper way to crimp a wire using a crimp connector?

To properly crimp a wire using a crimp connector, follow these steps:

- Strip the insulation from the wire to the specified length.

- Insert the wire into the barrel of the crimp connector.

- Use a crimping tool to compress the connector around the wire.

- Inspect the finished crimp to ensure that it is secure.

8. What are the different types of crimp connectors?

There are many different types of crimp connectors available, each designed for a specific purpose. Some of the most common types include:

- Butt connectors

- Ring connectors

- Spade connectors

- Bullet connectors

9. What is the difference between a male and female crimp connector?

Male crimp connectors have a pin or blade that inserts into a female connector. Female crimp connectors have a socket or receptacle that accepts a male connector.

10. What are the safety precautions that should be taken when working with crimp connectors?

When working with crimp connectors, it is important to take the following safety precautions:

- Always wear appropriate safety gear, such as safety glasses and gloves.

- Do not work on live circuits.

- Use the correct tools for the job.

- Inspect the connectors before using them.

- Follow the manufacturer’s instructions for use.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Push Connector Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Push Connector Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Push Connector Assembler plays a crucial role in the manufacturing process, ensuring the assembly and inspection of high-quality electrical push connectors. Key job responsibilities include:

1. Connector Assembly

Assembling and crimping electrical push connectors according to established specifications and procedures.

- Selecting and preparing appropriate components.

- Crimping terminals onto wires using specialized tools.

2. Quality Control

Conducting thorough inspections to ensure connectors meet required standards.

- Performing visual and dimensional checks.

- Testing for electrical continuity and insulation resistance.

3. Inventory Management

Maintaining and managing inventory levels of materials and supplies.

- Monitoring stock levels.

- Ordering and receiving new materials as needed.

4. Equipment Maintenance

Ensuring proper operation of assembly equipment.

- Performing routine maintenance and calibrations.

- Troubleshooting and resolving equipment issues.

Interview Tips

To ace the interview for the position of Push Connector Assembler, follow these preparation tips:

1. Research the Industry and Company

Familiarize yourself with the electrical industry, including the specific products and processes related to push connectors. Research the company’s history, mission, and values to demonstrate your interest and alignment.

2. Highlight Your Technical Skills

Emphasize your experience in electrical assembly and quality control. Provide specific examples of your ability to assemble and inspect push connectors to precise specifications.

3. Showcase Your Attention to Detail

Stress your keen attention to detail and ability to consistently meet high standards. Explain how you ensure accuracy and precision in your work.

4. Prepare for Common Interview Questions

Practice answering common interview questions such as:

- “Tell us about your experience in assembling electrical connectors.”

- “How do you ensure the quality of your work?”

- “What are your strengths and weaknesses as a Push Connector Assembler?”

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive at the interview location on time to demonstrate respect for the interviewer and position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Push Connector Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!