Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Putty and Caulking Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Putty and Caulking Supervisor so you can tailor your answers to impress potential employers.

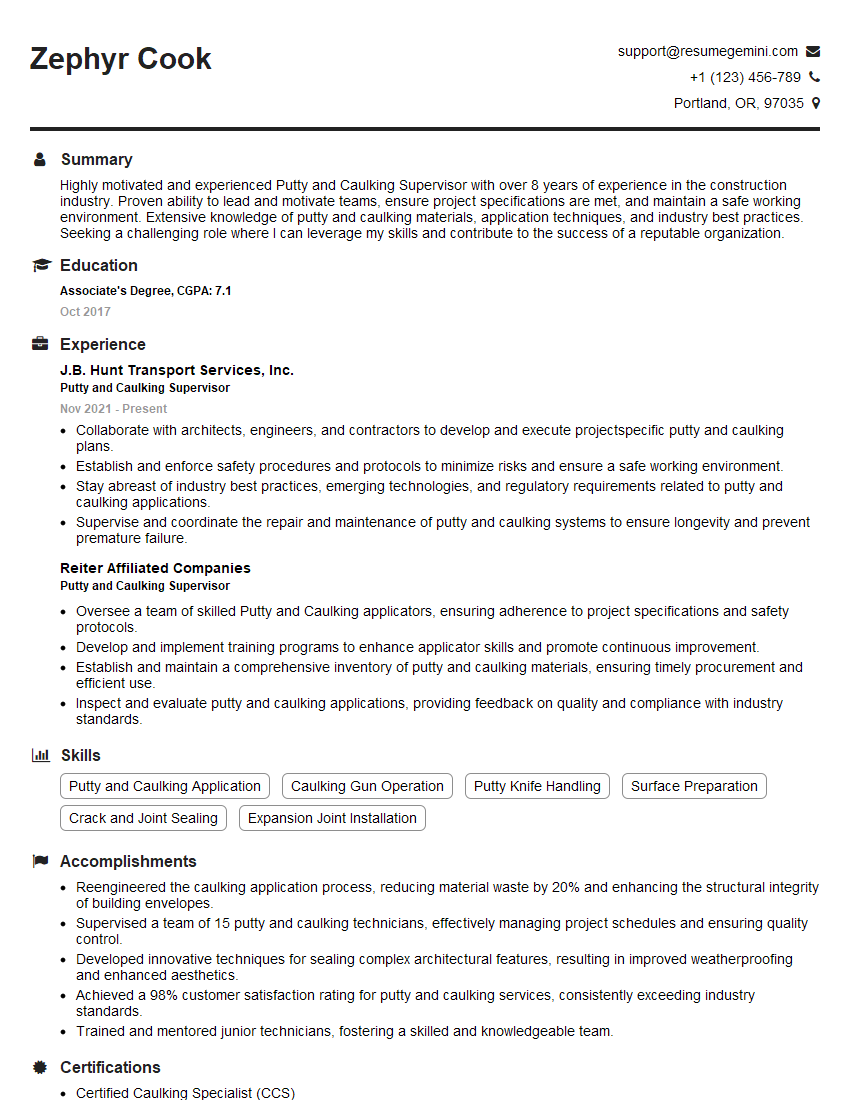

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Putty and Caulking Supervisor

1. What are the different types of putty and caulking materials, and when would you use each type?

Answer:

- Oil-based putty: A traditional type of putty made from linseed oil and whiting. It is durable, waterproof, and paintable, making it suitable for exterior applications and filling gaps in wood.

- Water-based putty: A more modern type of putty made from acrylic resins. It is easy to apply, dries quickly, and can be painted over. It is suitable for interior applications and filling small holes and cracks.

- Silicone caulk: A flexible, waterproof caulk made from silicone polymers. It is used for sealing joints around windows, doors, and other openings to prevent water infiltration.

- Acrylic latex caulk: A water-based caulk made from acrylic resins. It is less flexible than silicone caulk but is easier to apply and clean up. It is suitable for interior and exterior applications.

- Polyurethane caulk: A strong, durable caulk made from polyurethane polymers. It is waterproof, paintable, and can be used for a variety of applications, including sealing joints around windows, doors, and other openings.

2. What are the proper techniques for preparing surfaces for putty and caulking application?

Surface Preparation for Putty:

- Clean the surface thoroughly to remove any dirt, dust, or debris.

- Sand the surface lightly to create a smooth, even surface.

- Apply a primer to the surface to improve adhesion.

Surface Preparation for Caulking:

- Clean the joint or opening thoroughly to remove any dirt, dust, or debris.

- Apply masking tape to the edges of the joint or opening to protect the surrounding surfaces.

- Apply a backer rod to the joint or opening to provide support for the caulk.

3. What are the common mistakes to avoid when applying putty and caulking?

Answer:

- Failing to prepare the surface properly.

- Applying putty or caulk too thinly or too thickly.

- Not smoothing the putty or caulk properly.

- Not allowing the putty or caulk to cure properly before painting or staining.

- Using the wrong type of putty or caulk for the application.

4. What are the safety precautions that should be taken when working with putty and caulking?

Answer:

- Wear gloves and safety glasses when handling putty or caulk.

- Ventilate the work area properly.

- Avoid contact with skin and eyes.

- Keep putty and caulk out of reach of children and pets.

- Dispose of putty and caulk properly according to local regulations.

5. How do you ensure the quality of putty and caulking work performed by your team?

Answer:

- Establish clear work standards and procedures.

- Provide training to team members on proper techniques.

- Inspect work regularly to ensure it meets quality standards.

- Get feedback from customers on the quality of work.

- Make adjustments to work processes as needed to improve quality.

6. What are the latest trends and advancements in putty and caulking materials and techniques?

Answer:

- Low-VOC and eco-friendly putty and caulk: These products emit fewer volatile organic compounds (VOCs), making them better for indoor air quality and the environment.

- Self-leveling caulk: This type of caulk flows and levels itself, making it easier to apply and achieve a smooth, professional finish.

- Paintable caulk: This type of caulk can be painted over, making it a more versatile option for a variety of applications.

- Caulking guns with adjustable flow rates: These guns allow you to control the flow rate of the caulk, making it easier to apply the correct amount.

7. How do you handle a situation where a customer is not satisfied with the putty or caulking work performed by your team?

Answer:

- Listen to the customer’s concerns and try to understand their perspective.

- Inspect the work to identify any areas that need improvement.

- Discuss the issue with the team member who performed the work.

- Develop a plan to address the customer’s concerns and improve the quality of the work.

- Follow up with the customer to ensure that they are satisfied with the resolution.

8. What is your experience in managing a team of putty and caulking applicators?

Answer:

- Describe your experience in leading and motivating a team.

- Explain how you set clear goals and expectations for your team.

- Provide examples of how you have successfully resolved conflicts and issues within your team.

- Discuss how you have fostered a positive and collaborative work environment.

9. What is your understanding of the industry standards and regulations related to putty and caulking work?

Answer:

- Describe your knowledge of the relevant industry standards and regulations.

- Explain how you stay up-to-date on the latest changes to industry standards and regulations.

- Provide examples of how you have applied industry standards and regulations to your work.

10. What are your career goals and how do you see this role contributing to your professional development?

Answer:

- Explain your career goals and how they align with the requirements of the role.

- Describe how the role will provide you with opportunities to learn and grow professionally.

- Express your enthusiasm for the role and your commitment to contributing to the success of the company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Putty and Caulking Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Putty and Caulking Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Putty and Caulking Supervisor is responsible for overseeing the application of putty and caulking in a construction or manufacturing setting. The key job responsibilities include:

1. Planning and Scheduling

The supervisor plans and schedules the work of putty and caulking crews, ensuring that projects are completed on time and within budget.

- Develops work schedules and assigns tasks to crew members.

- Coordinates with other trades to ensure that work is completed in a timely and efficient manner.

2. Quality Control

The supervisor ensures that putty and caulking are applied according to specifications and industry standards.

- Inspects putty and caulking applications to ensure that they meet quality standards.

- Provides training and guidance to crew members on proper application techniques.

3. Safety Management

The supervisor ensures that crew members follow all safety protocols and regulations.

- Develops and implements safety procedures for putty and caulking applications.

- Provides safety training to crew members and monitors their compliance with safety regulations.

4. Materials Management

The supervisor manages the inventory of putty and caulking materials, ensuring that there is always enough supply on hand.

- Orders putty and caulking materials as needed.

- Monitors inventory levels and ensures that there is no shortage of materials.

Interview Tips

To ace the interview for a Putty and Caulking Supervisor position, candidates should:

1. Research the Company and Position

Candidates should thoroughly research the company and the specific position they are applying for. This will help them understand the company’s culture, values, and goals, as well as the specific responsibilities and expectations of the role.

- Visit the company’s website and social media pages.

- Read industry news and articles to learn about the latest trends and developments.

- Network with people who work for the company or in the industry.

2. Practice Answering Interview Questions

Candidates should practice answering common interview questions, such as:

- Tell me about your experience in putty and caulking.

- What are the most important qualities of a successful Putty and Caulking Supervisor?

- How do you ensure that putty and caulking are applied according to specifications?

3. Prepare Questions to Ask the Interviewer

Candidates should prepare questions to ask the interviewer at the end of the interview. This shows that they are engaged and interested in the position and the company.

- What are the biggest challenges facing the Putty and Caulking department?

- What are the company’s goals for the future?

- How does the company support professional development and growth?

4. Dress Professionally and Arrive on Time

Candidates should dress professionally and arrive on time for the interview. This shows that they respect the interviewer and the company.

- Wear a suit or business casual attire.

- Be punctual and arrive a few minutes early for the interview.

5. Be Confident and Enthusiastic

Candidates should be confident and enthusiastic during the interview. This shows that they are passionate about the position and the company.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be positive and enthusiastic about the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Putty and Caulking Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.