Are you gearing up for a career in Putty Mixer and Applier? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Putty Mixer and Applier and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

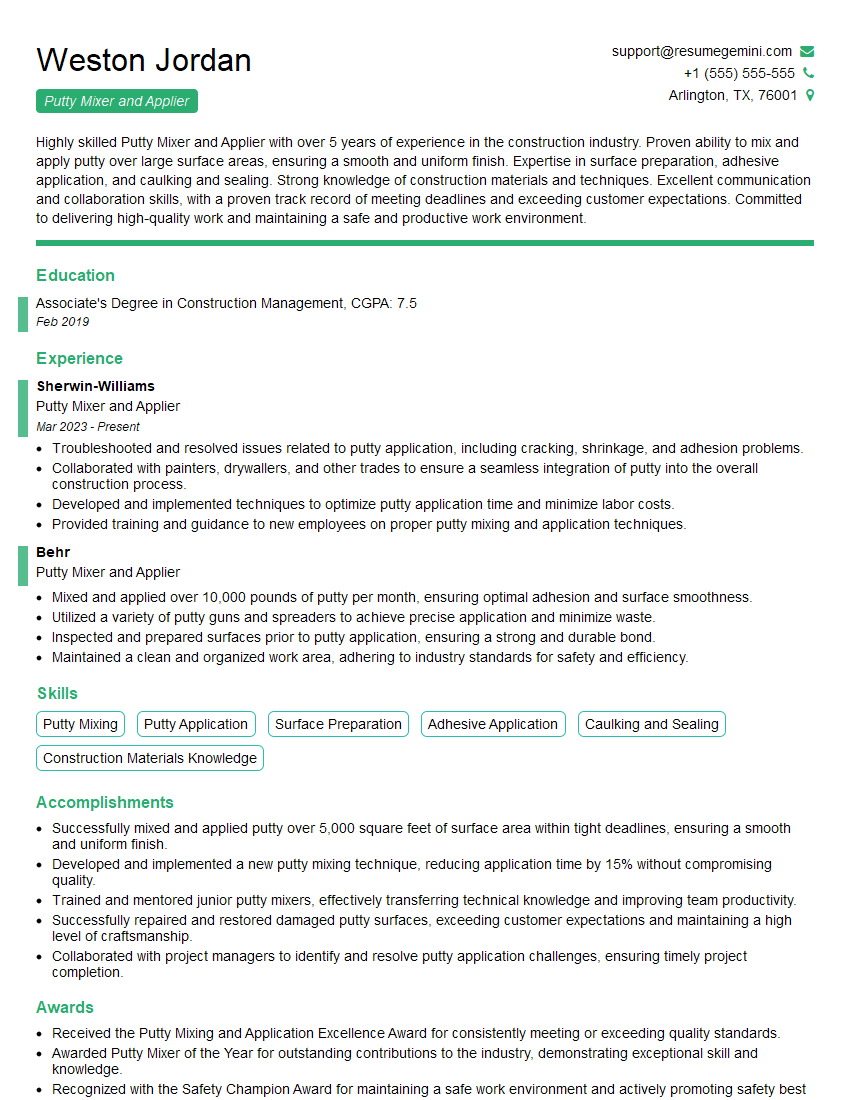

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Putty Mixer and Applier

1. Explain the process of mixing putty according to the manufacturer’s specifications.

- Read and understand the manufacturer’s instructions carefully.

- Gather the necessary tools and equipment, including a mixing paddle, bucket, and water.

- Measure out the correct proportions of putty and water as per the instructions.

- Place the putty into the bucket and gradually add the water while mixing thoroughly.

- Continue mixing until the putty reaches the desired consistency, which should be smooth and lump-free.

- Allow the putty to rest for a short period to allow any air bubbles to escape.

2. Describe the different types of putty applicators and their uses.

Putty Knives

- Used for applying and shaping putty in various thicknesses.

- Available in different sizes and shapes to suit different applications.

Caulking Guns

- Used for applying putty in precise lines or beads.

- Dispenses putty evenly and efficiently.

Trowels

- Used for applying large quantities of putty over wide areas.

- Provides a smooth and even finish.

3. Explain the techniques for applying putty to different surfaces, such as wood, drywall, and metal.

- Wood: Apply a thin layer of putty using a putty knife, filling any gaps or holes. Smooth the putty with the knife to achieve a level finish.

- Drywall: Use a putty knife to apply putty over drywall seams and imperfections. Spread the putty evenly and allow it to dry before sanding to a smooth finish.

- Metal: Clean the metal surface thoroughly before applying putty. Use a putty knife to spread the putty thinly and smoothly, filling any dents or scratches.

4. Describe the safety precautions to be taken when mixing and applying putty.

- Wear gloves and a mask to prevent contact with hazardous materials.

- Ensure proper ventilation in the work area to avoid inhaling harmful fumes.

- Handle sharp tools with care to prevent cuts or injuries.

- Clean up spills and waste materials promptly to maintain a safe work environment.

5. Explain the process of preparing a surface for putty application to ensure proper adhesion.

- Clean the surface thoroughly to remove any dirt, grease, or debris.

- Sand the surface lightly to create a rough texture for better adhesion.

- Apply a primer to the surface to enhance the bond between the putty and the substrate.

6. Describe the techniques for sanding putty to achieve a smooth and even finish.

- Use sandpaper of appropriate grit, starting with a coarse grit and gradually moving to a finer grit.

- Sand the putty in circular motions, applying light pressure.

- Feather the edges of the putty to blend it seamlessly with the surrounding surface.

7. Explain the importance of proper curing time for putty before painting or further finishing.

- Curing allows the putty to fully harden and develop its maximum strength.

- Prevents the putty from shrinking or cracking after application.

- Ensures a durable and long-lasting finish.

8. Describe the different types of putty available and their specific applications.

- Wood Putty: Used to fill cracks, holes, and imperfections in wood surfaces.

- Drywall Putty: Used to repair and smooth drywall seams and imperfections.

- Metal Putty: Used to fill dents and scratches in metal surfaces.

- Epoxy Putty: Used for heavy-duty repairs and bonding of various materials.

9. Explain the importance of following the manufacturer’s instructions when mixing and applying putty.

- Ensures the putty achieves its intended purpose and performance.

- Prevents errors or misapplications that could compromise the outcome.

- Helps avoid potential health and safety hazards.

10. Describe your experience in using different putty applicators and achieving desired finishes.

- Explain your proficiency in handling various putty applicators, such as putty knives, caulking guns, and trowels.

- Provide examples of projects where you successfully applied putty to achieve smooth and professional-looking finishes.

- Highlight your ability to adapt to different surface types and application techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Putty Mixer and Applier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Putty Mixer and Applier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Putty Mixers and Appliers play a crucial role in the construction industry, ensuring the proper application of putty for various purposes. Their responsibilities encompass:

1. Putty Preparation and Mixing

Accurately measuring and mixing different types of putty, including epoxy, acrylic, and gypsum-based putty, as per manufacturer’s specifications.

- Following prescribed mixing ratios and techniques to achieve the desired consistency and workability.

- Using specialized equipment and tools, such as putty mixers and spatulas, to ensure thorough mixing and prevent lumps.

2. Putty Application

Applying putty to various surfaces, such as walls, ceilings, and joints, to fill gaps, level uneven surfaces, or create decorative effects.

- Selecting appropriate putty knives and applicators based on the task and surface conditions.

- Skilfully applying putty using smooth and even strokes to achieve a uniform and aesthetically pleasing finish.

3. Surface Preparation and Finishing

Preparing surfaces prior to putty application by cleaning, sanding, and priming to ensure proper adhesion and a smooth finish.

- Inspecting surfaces for any imperfections or debris that may hinder putty application.

- Applying primers or bonding agents to enhance the adhesion of putty to the surface.

4. Safety Compliance and Maintenance

Adhering to established safety protocols and guidelines while mixing and applying putty.

- Wearing appropriate personal protective equipment, such as gloves, masks, and safety glasses.

- Properly disposing of putty waste and cleaning equipment and tools after use.

Interview Tips

To ace an interview for a Putty Mixer and Applier position, candidates should:

1. Research the Company and Industry

Familiarize themselves with the company’s background, values, and recent projects to demonstrate their interest and knowledge of the industry.

- Research industry trends and best practices to showcase their understanding of the field.

- Prepare questions that demonstrate their curiosity and enthusiasm about the company and the role.

2. Highlight Relevant Experience and Skills

Emphasize previous experience or training in putty mixing and application, including specific techniques and materials used.

- Showcase their ability to work independently and as part of a team in a construction setting.

- Demonstrate their attention to detail and commitment to delivering high-quality results.

3. Showcase Safety Awareness and Compliance

Highlight their understanding of safety protocols and regulations related to putty mixing and application.

- Explain their knowledge of proper handling, storage, and disposal of putty and related materials.

- Emphasize their commitment to maintaining a safe work environment.

4. Practice and Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful and specific answers that showcase their qualifications and enthusiasm for the role.

- Practice answering questions about their experience, skills, and motivation for applying.

- Prepare questions to ask the interviewer that demonstrate their interest and engagement.

Next Step:

Now that you’re armed with the knowledge of Putty Mixer and Applier interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Putty Mixer and Applier positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini