Are you gearing up for an interview for a PVC Loader (Polyvinyl Chloride Loader) position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for PVC Loader (Polyvinyl Chloride Loader) and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

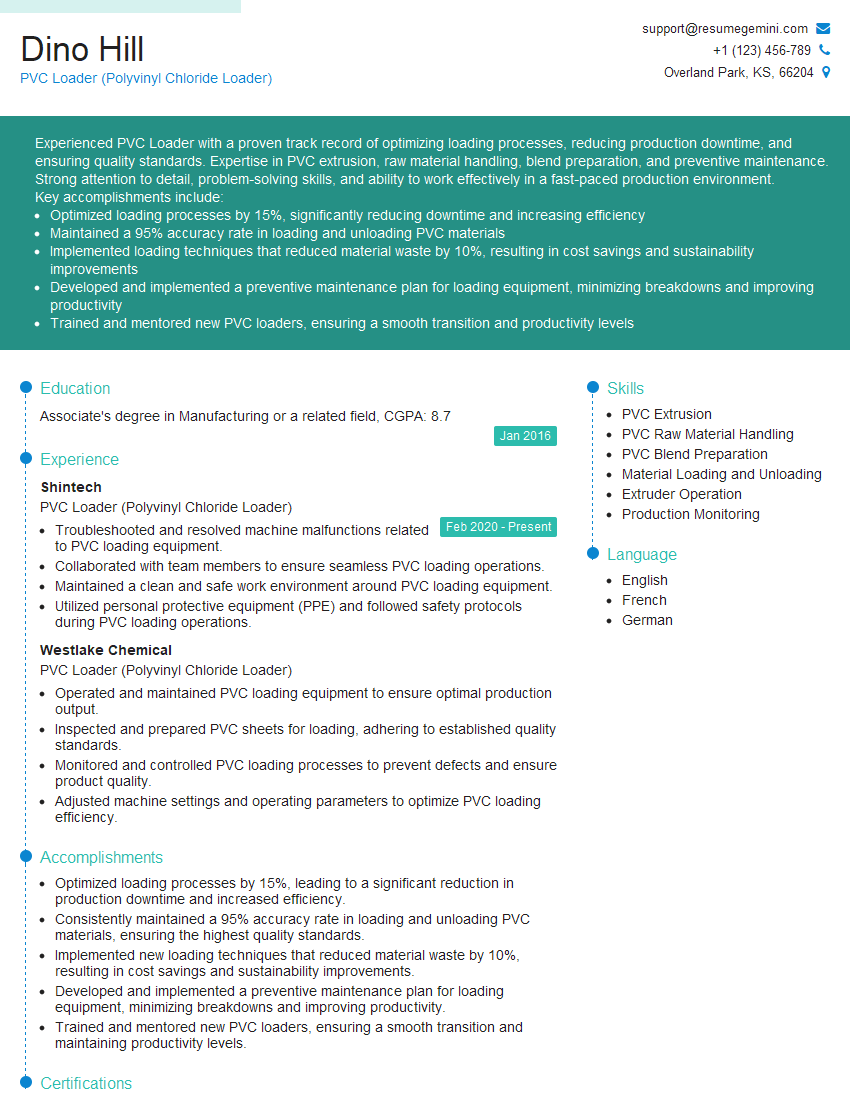

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For PVC Loader (Polyvinyl Chloride Loader)

1. Explain the steps involved in loading PVC materials into the machine?

- Prepare the machine by checking if it is clean and ready to use.

- Wear appropriate safety gear such as gloves, safety glasses, and a mask.

- Identify the type of PVC material to be loaded and ensure it is compatible with the machine.

- Set the machine to the correct temperature and speed for the PVC material.

- Load the PVC material into the hopper or feed tray of the machine.

- Monitor the loading process to ensure that the material is being fed into the machine correctly.

- Adjust the machine settings as needed to optimize the loading process.

- Once the PVC material is fully loaded, check for any blockages or issues with the machine.

2. What are the different types of PVC materials and their properties?

Types of PVC Materials

- Rigid PVC (RPVC): Strong, durable, and resistant to impact.

- Flexible PVC (FPVC): Soft, pliable, and easy to bend.

- Chlorinated Polyvinyl Chloride (CPVC): High-temperature resistance and chemical resistance.

- PVC Foam: Lightweight, insulative, and sound-absorbing.

- PVC Pipe: Used for plumbing, drainage, and electrical applications.

Properties of PVC Materials

- Lightweight

- Durable and impact-resistant

- Resistant to chemicals and corrosion

- Fire-resistant

- Easy to process and fabricate

3. How do you maintain the PVC loading machine to ensure optimal performance?

- Regularly clean the machine to remove any debris or PVC residue.

- Inspect the machine for any worn or damaged parts and replace them as needed.

- Lubricate the machine’s moving parts to ensure smooth operation.

- Calibrate the machine to ensure accurate loading and dispensing.

- Follow the manufacturer’s recommended maintenance schedule.

- Keep a maintenance log to track repairs and replacements.

4. What are the safety precautions that should be taken when operating a PVC loading machine?

- Wear appropriate safety gear, including gloves, safety glasses, and a mask.

- Operate the machine in a well-ventilated area.

- Never reach into the machine while it is running.

- Be aware of the machine’s moving parts and pinch points.

- Keep the work area clean and free of obstructions.

- Read and understand the machine’s operating manual.

- Follow all safety instructions provided by the manufacturer.

5. How do you troubleshoot common problems that may occur during PVC loading?

- Material not loading properly: Check if the material is compatible with the machine, adjust the machine settings, and clear any blockages.

- Material overflowing: Reduce the loading speed, check for blockages, and adjust the machine settings.

- Machine overheating: Stop the machine, allow it to cool down, and check for any blockages or issues with the cooling system.

- Leaks in the machine: Identify the source of the leak, tighten any loose connections, and replace damaged parts as needed.

- Electrical problems: Check the power supply, fuses, and wiring, and contact an electrician if necessary.

6. What quality control measures do you follow to ensure the accuracy and consistency of PVC loading?

- Regularly calibrate the machine to ensure accurate loading and dispensing.

- Inspect the PVC material before loading to ensure it is consistent in quality.

- Monitor the loading process to ensure that the material is being loaded correctly.

- Weigh or measure the loaded material to verify its accuracy.

- Keep a record of loading operations to track performance and identify any potential issues.

7. How do you handle unexpected situations or emergencies that may arise during PVC loading?

- Remain calm and assess the situation.

- Follow established safety procedures, such as stopping the machine and disconnecting the power supply.

- Identify the cause of the emergency and take steps to mitigate it.

- Contact a supervisor or engineer for assistance if needed.

- Document the emergency and any actions taken.

8. How do you stay up-to-date with the latest advancements and best practices in PVC loading?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Network with other PVC loading professionals.

- Take online courses or certifications.

- Stay informed about new technologies and equipment.

9. How do you prioritize your tasks and manage your time effectively when working in a fast-paced PVC loading environment?

- Set clear priorities and focus on the most important tasks first.

- Use a to-do list or task management system to track your progress.

- Delegate tasks to others when possible.

- Take breaks throughout the day to avoid burnout and maintain focus.

- Communicate with your supervisor and colleagues to ensure everyone is aligned on priorities.

10. Why are you interested in working as a PVC Loader in our company specifically?

- Your company’s reputation for producing high-quality PVC products.

- The opportunity to contribute to your company’s success.

- The chance to work with a team of experienced PVC professionals.

- The potential for career growth within your company.

- The company’s commitment to safety and environmental sustainability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for PVC Loader (Polyvinyl Chloride Loader).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the PVC Loader (Polyvinyl Chloride Loader)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A PVC Loader, also known as a Polyvinyl Chloride Loader, plays a crucial role in the manufacturing industry by loading and unloading Polyvinyl Chloride (PVC) materials.

1. Loading and Unloading PVC Materials

The primary responsibility of a PVC Loader is to load PVC materials into machines and equipment used in the production process. This involves lifting heavy bags or containers of PVC pellets and carefully pouring them into designated hoppers or conveyors.

- Safely and efficiently operate forklifts or other material handling equipment to move PVC materials.

- Ensure proper loading techniques to prevent spillage, contamination, and accidents.

2. Monitoring Equipment

PVC Loaders are responsible for monitoring the equipment used in the PVC loading process. They ensure that the machines are operating correctly and that the PVC materials are being loaded and unloaded properly.

- Check equipment settings, such as temperature and pressure, to ensure optimal performance.

- Identify and troubleshoot minor equipment problems and notify supervisors of any major issues.

3. Quality Control

PVC Loaders are involved in maintaining the quality of PVC materials. They inspect the incoming PVC pellets for any contamination or defects and ensure that the loaded materials meet the required specifications.

- Visually inspect PVC pellets and reject any that are damaged or contaminated.

- Follow established quality control procedures to ensure the accuracy and consistency of PVC loading operations.

4. Safety and Compliance

PVC Loaders prioritize safety and compliance in their work. They adhere to established health and safety regulations and wear appropriate personal protective equipment.

- Follow all safety protocols, including proper lifting techniques and machine operation.

- Maintain a clean and organized work area to prevent accidents and contamination.

Interview Tips

To ace an interview for a PVC Loader position, candidates should prepare thoroughly by understanding the key responsibilities of the role and practicing common interview questions. Here are some helpful tips:

1. Research the Company and Position

Before the interview, research the company and the specific PVC Loader position. Familiarize yourself with the company’s products, services, and industry standing. Understand the job description thoroughly and identify the key skills and experience required.

- Visit the company’s website and social media pages to gather information.

- Read industry publications and news articles to stay updated on the latest trends.

2. Practice Common Interview Questions

Practice answering common interview questions related to the PVC Loader role. Prepare concise and clear responses that highlight your relevant skills and experience. Focus on demonstrating your strong work ethic, attention to detail, and commitment to safety.

- “Tell us about your experience in loading and unloading PVC materials.”

- “How do you ensure the quality and accuracy of PVC loading operations?”

3. Highlight Safety and Compliance

Emphasize your understanding of safety protocols and your commitment to compliance. Explain how you prioritize safety in your work and have a strong track record of accident prevention.

- Share examples of how you have successfully followed safety procedures.

- Describe your knowledge of industry regulations and standards.

4. Use Specific Examples

When answering interview questions, provide specific examples from your past work experience that demonstrate your skills and abilities. Use the STAR method (Situation, Task, Action, Result) to describe your experiences and highlight the positive impact you have had.

- For example, you could describe a time when you successfully identified and resolved a minor equipment issue that prevented production delays.

5. Be Confident and Enthusiastic

Throughout the interview, maintain a positive and confident demeanor. Show enthusiasm for the role and express your interest in joining the company. Ask thoughtful questions to demonstrate your engagement and willingness to learn.

- Practice your answers in front of a mirror or with a friend.

- Dress professionally and arrive on time for your interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the PVC Loader (Polyvinyl Chloride Loader) role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.