Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pyrometer Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

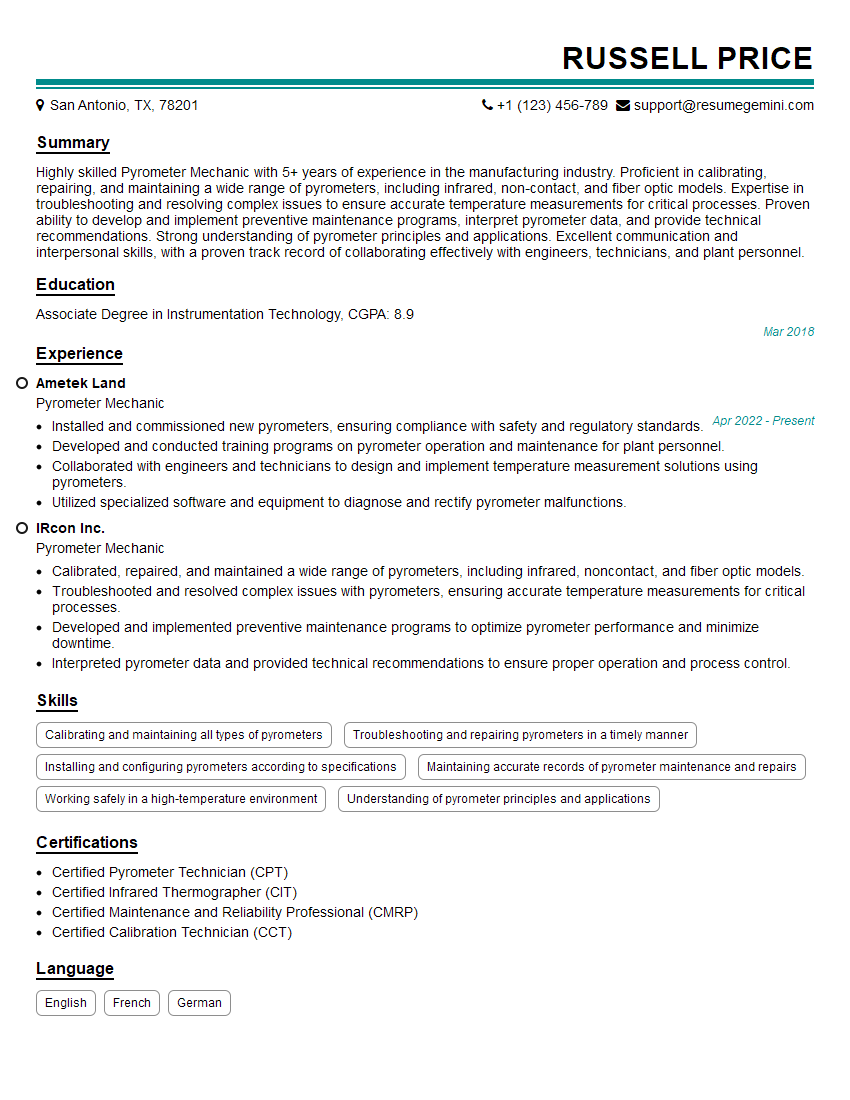

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pyrometer Mechanic

1. Describe the process of calibrating a pyrometer?

The process of calibrating a pyrometer involves the following steps:

- Set up the pyrometer and target.

- Adjust the pyrometer’s emissivity setting.

- Heat the target to a known temperature.

- Measure the target’s temperature with the pyrometer.

- Compare the measured temperature to the known temperature.

- Adjust the pyrometer’s calibration if necessary.

2. What are the different types of pyrometers and how are they used?

Non-Contact Pyrometers:

- Infrared Pyrometers: Measure surface temperatures by detecting infrared radiation emitted by the target.

- Laser Pyrometers: Use a laser beam to measure the temperature of a very small area.

Contact Pyrometers:

- Thermocouples: Measure temperature by creating a voltage proportional to the temperature difference between the probe and the reference junction.

- Resistance Temperature Detectors (RTDs): Measure temperature by changing resistance with temperature.

3. What are the most common problems encountered with pyrometers and how do you troubleshoot them?

- Inaccurate Readings: Check calibration, target emissivity, and distance to target.

- Drifting Readings: Check for loose connections, faulty components, or environmental interference.

- Damaged Probe: Replace the probe or repair it if possible.

- Power Issues: Check the battery or power supply and replace if necessary.

4. What safety precautions should be taken when using pyrometers?

- Wear appropriate personal protective equipment (PPE), including gloves and eye protection.

- Do not point the pyrometer at people or flammable materials.

- Keep the pyrometer clean and free of debris.

- Follow the manufacturer’s instructions for safe operation.

5. How do you maintain and store pyrometers properly?

- Clean the pyrometer after each use.

- Store the pyrometer in a dry, clean environment.

- Calibrate the pyrometer regularly.

- Follow the manufacturer’s instructions for proper storage and maintenance.

6. What are the different components of a pyrometer and how do they work together?

- Sensor: Detects the temperature of the target.

- Signal Conditioner: Converts the sensor’s output into a usable signal.

- Display: Shows the measured temperature.

7. What is the difference between emissivity and reflectivity?

- Emissivity: The ability of a material to emit infrared radiation.

- Reflectivity: The ability of a material to reflect infrared radiation.

8. How does the distance from the target affect the accuracy of a pyrometer?

- The further the distance, the less accurate the pyrometer becomes.

- Factors to consider include target size, field of view, and distance-to-target ratio.

9. What are the advantages and disadvantages of using a pyrometer?

Advantages:

- Non-contact temperature measurement.

- Quick and easy to use.

- Can measure temperatures in hazardous or inaccessible areas.

Disadvantages:

- Inaccurate readings if the target emissivity or distance is incorrect.

- Requires regular calibration.

- Can be affected by environmental factors such as dust, smoke, or fog.

10. How do you troubleshoot a pyrometer that is giving inconsistent readings?

- Check the calibration.

- Ensure the target is clean and free of debris.

- Check the distance to the target and adjust accordingly.

- Inspect the sensor for damage or contamination.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pyrometer Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pyrometer Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Pyrometer Mechanic

Pyrometer Mechanics play a crucial role in maintaining the accuracy and functionality of pyrometers, which are devices used to measure extremely high temperatures in industrial settings.

1. Pyrometer Calibration and Maintenance

Pyrometer Mechanics are responsible for calibrating and maintaining pyrometers to ensure their accuracy and reliability. They use specialized equipment and follow established procedures to adjust and verify the pyrometer’s performance.

2. Troubleshooting and Repair

When pyrometers malfunction or fail, Pyrometer Mechanics diagnose and repair the issues. They analyze electrical and mechanical components, replace defective parts, and verify the proper functioning of the pyrometer after repairs.

3. Equipment Inspection and Documentation

Regular inspection and documentation of pyrometer equipment are essential for preventive maintenance. Pyrometer Mechanics conduct routine inspections to identify potential issues and document their findings. They maintain accurate records of calibrations, repairs, and inspections to ensure compliance with industry standards.

4. Collaboration with Other Teams

Pyrometer Mechanics often collaborate with other teams, such as engineers and production technicians, to resolve complex issues related to pyrometer performance and integration within industrial processes.

Interview Preparation Tips for Pyrometer Mechanics

To ace an interview for a Pyrometer Mechanic position, it is crucial to prepare thoroughly and demonstrate your expertise in the field.

1. Research the Company and Position

Familiarize yourself with the company’s history, products or services, and its industry. Research the specific Pyrometer Mechanic position to understand the requirements and expectations.

2. Highlight Your Relevant Skills and Experience

Emphasize your technical skills in pyrometer calibration, maintenance, and repair. Provide specific examples of your experience in these areas and highlight your ability to identify and resolve complex issues.

3. Showcase Your Precision and Attention to Detail

Pyrometer Mechanics must be meticulous and pay close attention to detail. During the interview, emphasize your adherence to industry standards, your ability to follow procedures precisely, and your commitment to delivering accurate results.

4. Prepare for Technical Questions

Interviewers may ask technical questions to assess your understanding of pyrometer principles, calibration techniques, and troubleshooting procedures. Prepare for these questions by reviewing fundamental concepts and practicing solving common pyrometer-related issues.

5. Demonstrate Your Communication Abilities

Effective communication is essential for coordinating with colleagues and resolving issues. During the interview, showcase your ability to communicate clearly and concisely, both verbally and in writing.

6. Emphasize Your Commitment to Safety

Working with pyrometers involves potential hazards. Emphasize your commitment to safety regulations and procedures, and highlight your experience in handling and operating equipment in a safe manner.

7. Consider Industry Certifications

Obtaining industry-recognized certifications, such as the Certified Pyrometer Technician (CPT) certification, can enhance your credibility and demonstrate your expertise.

Next Step:

Now that you’re armed with the knowledge of Pyrometer Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pyrometer Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini