Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Quality Control Expert position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

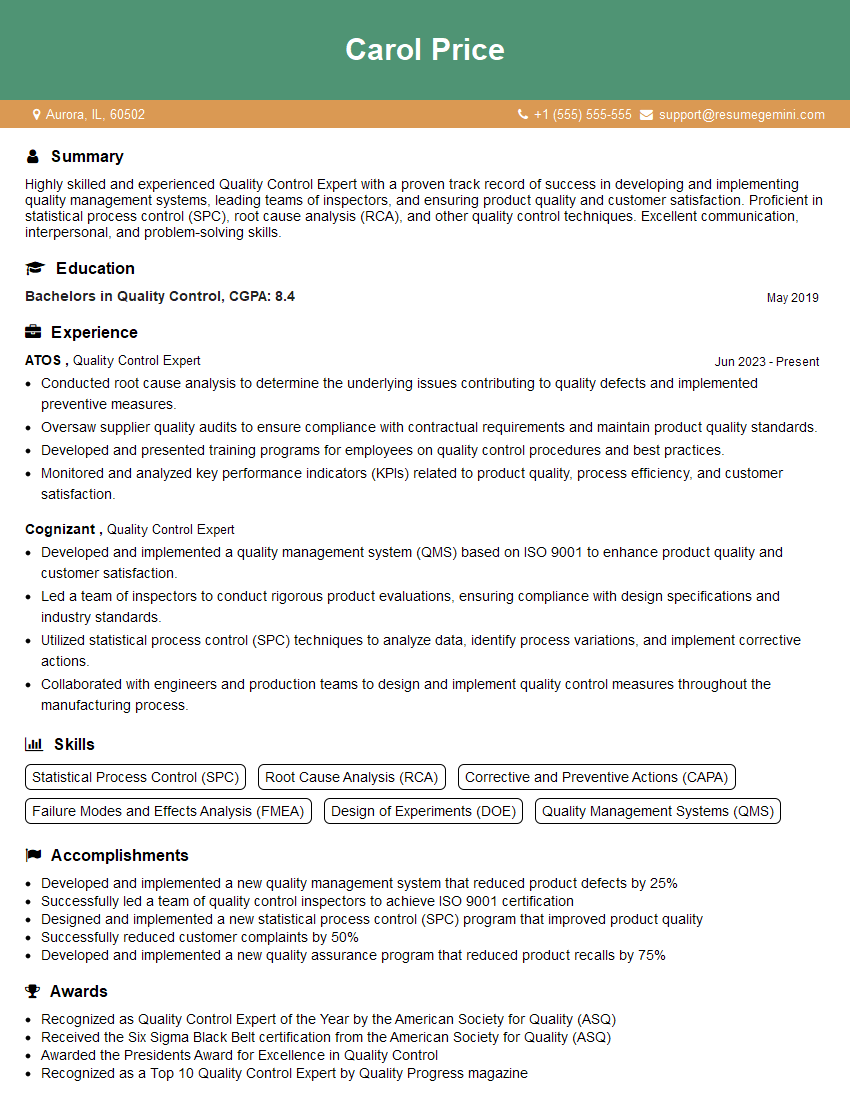

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Quality Control Expert

1. Explain the different types of quality control inspections and the situations where each type would be most appropriate?

There are various types of quality control inspections, each suited to specific situations:

- In-process inspection: Conducted during production to identify and correct defects in real-time, minimizing waste and rework.

- Final inspection: Performed on completed products before packaging and shipment to ensure they meet specifications and customer requirements.

- Random sampling inspection: Involves selecting a subset of products from a lot and inspecting them to estimate the quality of the entire lot.

- Statistical process control (SPC): Uses statistical techniques to monitor and control production processes, identifying deviations from established standards.

2. Describe the key principles and tools of Six Sigma methodology.

DMAIC Cycle

- Define: Establish the problem statement and project goals.

- Measure: Collect and analyze data to quantify the problem.

- Analyze: Identify the root causes of the problem.

- Improve: Implement solutions to eliminate or reduce the root causes.

- Control: Monitor and sustain the improvements over time.

Tools

- Process mapping: Visualizing and analyzing production processes to identify inefficiencies and potential problems.

- Statistical analysis: Using statistical techniques to analyze data and identify trends and relationships.

3. Explain the role of quality control in ensuring product safety and regulatory compliance.

Quality control plays a crucial role in product safety and regulatory compliance by:

- Identifying and eliminating defects: Preventing the production and distribution of unsafe or non-compliant products.

- Meeting industry standards: Adhering to established quality and safety standards, ensuring products meet regulatory requirements.

- Providing documentation and evidence: Maintaining records and documentation of quality control processes to demonstrate compliance with regulations.

4. Describe the benefits of implementing a quality management system (QMS) in a manufacturing environment.

Implementing a QMS in manufacturing offers numerous benefits:

- Improved product quality: Standardizing processes and reducing defects.

- Enhanced efficiency: Streamlining operations and eliminating waste.

- Reduced costs: Minimizing rework, scrap, and warranty claims.

- Increased customer satisfaction: Delivering high-quality products that meet customer expectations.

- Improved employee morale: Fostering a culture of quality and accountability.

5. Explain the importance of continuous improvement in quality control.

Continuous improvement is crucial for quality control because it:

- Identifies areas for improvement: Regularly reviewing and assessing processes to identify potential weaknesses.

- Keeps pace with changing standards: Adapting to evolving industry standards and customer requirements.

- Prevents complacency: Encouraging a mindset of continuous improvement to prevent stagnation and ensure ongoing quality.

6. Describe the role of data analysis in quality control.

Data analysis plays a vital role in quality control by:

- Identifying trends and patterns: Analyzing data to identify potential problems or areas for improvement.

- Evaluating effectiveness of quality control measures: Measuring the effectiveness of implemented quality control processes.

- Making data-driven decisions: Providing quantitative evidence to support quality control decisions.

7. Explain the principles of root cause analysis and its importance in quality control.

Root cause analysis is a key principle in quality control because it:

- Unveils underlying causes: Identifying the root causes of problems helps prevent recurrence.

- Supports effective corrective actions: Understanding the root causes enables the development of effective solutions.

- Promotes learning and improvement: Analyzing root causes fosters organizational learning and continuous improvement.

8. Describe the different types of quality control charts and their respective uses.

Common types of quality control charts include:

- Control chart for variables: Monitoring continuous data, such as measurements or weights.

- Control chart for attributes: Monitoring discrete data, such as the number of defects or successes.

- Run chart: Plotting data over time to detect trends and shifts.

- Scatter plot: Analyzing the relationship between two variables.

- Histogram: Displaying the frequency distribution of data.

9. Explain the significance of supplier quality management in ensuring overall product quality.

Supplier quality management is crucial because it:

- Ensures reliable materials and components: Verifying that suppliers meet quality standards to maintain product quality.

- Minimizes risks and disruptions: Assessing supplier capabilities and reliability to prevent supply chain disruptions.

- Fosters collaboration and improvement: Working with suppliers to improve quality and reduce defects.

10. Describe your approach to training and developing a quality control team.

My approach to training and developing a quality control team involves:

- Needs assessment: Identifying training needs based on current skill gaps and future requirements.

- Customized training programs: Developing training programs tailored to specific roles and responsibilities.

- Mentoring and coaching: Providing support and guidance to team members to enhance their skills.

- Continuous evaluation: Regularly assessing training effectiveness and making adjustments as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Quality Control Expert.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Quality Control Expert‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Quality Control Expert, you will play a crucial role in ensuring the quality and safety of products and services across the organization. Your key responsibilities include:

1. Quality Management

Develop and implement quality control plans and procedures to ensure compliance with industry standards and regulations.

- Establish quality control metrics and monitor performance to identify areas for improvement.

- Conduct regular quality audits and inspections to assess the effectiveness of quality control systems.

2. Product Testing

Design and execute product testing protocols to evaluate the performance and quality of products.

- Analyze test results and identify potential defects or areas of improvement.

- Provide feedback to engineering and production teams to address quality issues and enhance product design.

3. Process Improvement

Identify and implement quality improvement initiatives to optimize processes and reduce defects.

- Collaborate with cross-functional teams to analyze quality data and identify root causes of problems.

- Develop and implement corrective and preventive actions to mitigate quality risks and improve overall quality.

4. Regulatory Compliance

Stay abreast of industry regulations and standards related to quality control.

- Ensure compliance with regulatory requirements and industry best practices.

- Participate in industry events and conferences to stay updated on quality control trends.

Interview Tips

To ace your interview for a Quality Control Expert position, consider the following preparation tips:

1. Research the Company and Role

Thoroughly research the company’s industry, products, and quality control initiatives. This will demonstrate your interest and understanding of the role.

- Review the company website, LinkedIn profile, and industry articles.

- Identify specific examples of the company’s commitment to quality and how you can contribute to their efforts.

2. Highlight Your Technical Skills

Emphasize your proficiency in quality control tools, methodologies, and industry standards.

- Provide examples of your experience in developing and executing quality control plans, performing product testing, and analyzing quality data.

- Quantify your accomplishments by providing specific metrics and results.

3. Demonstrate Problem-Solving Abilities

Quality Control Experts are often faced with complex quality issues. Highlight your ability to identify root causes, develop effective solutions, and implement corrective actions.

- Describe a time when you successfully resolved a quality problem.

- Explain your approach to problem-solving and how you ensure the effectiveness of your solutions.

4. Showcase Your Communication and Teamwork Skills

Quality Control Experts often work with cross-functional teams. Demonstrate your ability to communicate effectively, collaborate with others, and build strong relationships.

- Provide examples of how you have successfully communicated quality issues and solutions to stakeholders at different levels.

- Explain how you contribute to a positive and collaborative team environment.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Quality Control Expert role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.