Are you gearing up for an interview for a Quality Control Industrial Engineer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Quality Control Industrial Engineer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

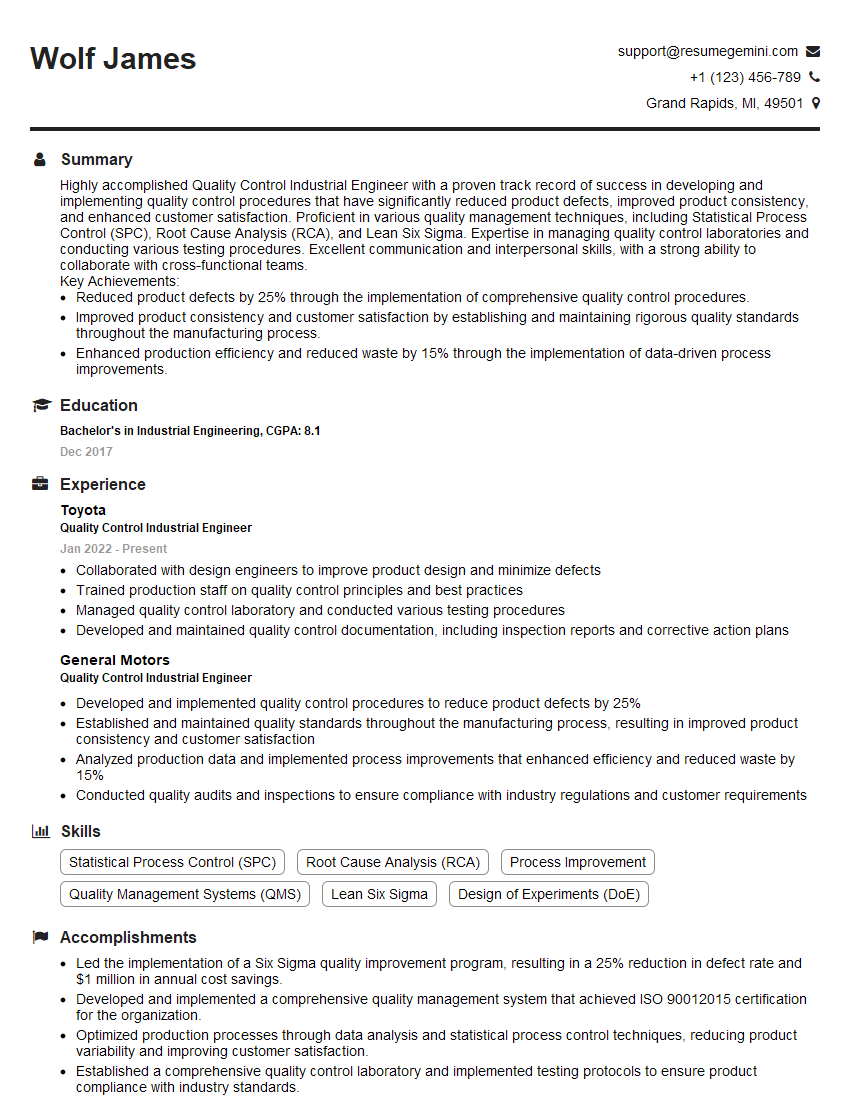

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Quality Control Industrial Engineer

1. Explain the principles of Six Sigma and how you have applied them in your previous role?

Answer:

- Six Sigma is a data-driven methodology that aims to improve processes by eliminating defects and reducing variation.

- Key principles include identifying and defining problems, collecting and analyzing data, developing and implementing solutions, and sustaining improvements.

- In my previous role, I led a Six Sigma project to reduce customer complaints by 25%. We used statistical analysis to identify the root cause of the issue, implemented process improvements, and monitored results to ensure sustained improvement.

2. Describe your experience in developing and implementing quality control plans?

Answer:

Planning and Development:

- Conduct thorough risk assessments to identify potential defects and non-conformances.

- Establish inspection criteria, sampling procedures, and acceptance limits based on industry standards and customer specifications.

- Develop detailed work instructions and checklists to ensure consistent execution.

Implementation:

- Train quality control inspectors on the plan and ensure they adhere to established procedures.

- Supervise inspection activities and ensure timely and accurate reporting of results.

- Analyze data to identify trends, deviations, and areas for improvement.

3. How do you prioritize quality control activities when faced with resource constraints?

Answer:

- Conduct a risk assessment to determine the potential impact of defects on customer safety, satisfaction, and business operations.

- Focus on critical control points where defects have the highest likelihood and impact.

- Develop a tiered inspection approach, with more rigorous inspections for high-risk areas and less stringent inspections for low-risk areas.

- Leverage technology and automation to streamline inspection processes and free up resources.

4. Explain your experience in using statistical process control (SPC) techniques?

Answer:

- Proficient in using SPC tools such as control charts, histograms, and scatterplots to monitor and analyze process data.

- Understand the principles of statistical inference and hypothesis testing.

- Able to identify and interpret trends, identify special causes of variation, and make recommendations for process improvement.

5. Describe your understanding of ISO 9001 and how you have implemented it in the past?

Answer:

- ISO 9001 is an international standard that sets out the requirements for a quality management system (QMS).

- Key elements include customer focus, leadership, engagement of people, process approach, improvement, evidence-based decision-making, and relationship management.

- In my previous role, I led the implementation of ISO 9001 in a manufacturing facility. We developed a comprehensive QMS that met all the requirements of the standard, resulting in improved product quality, increased customer satisfaction, and reduced operating costs.

6. How do you handle customer complaints related to product quality?

Answer:

- Establish a robust complaint management process to promptly and thoroughly investigate customer concerns.

- Analyze complaints to identify trends and underlying causes.

- Collaborate with production, engineering, and other departments to develop and implement corrective and preventive actions.

- Provide clear and timely feedback to customers, keeping them informed of the progress and resolution of their complaints.

7. Describe your approach to educating and training employees on quality standards and practices?

Answer:

- Develop a comprehensive training program that covers all aspects of quality control, from inspection techniques to statistical analysis.

- Use a variety of training methods, including classroom lectures, practical exercises, and online modules.

- Assess employee understanding through regular evaluations and provide ongoing support and coaching.

- Foster a culture of continuous learning and improvement, encouraging employees to identify and address quality issues.

8. How do you stay up-to-date on the latest quality control techniques and technologies?

Answer:

- Attend industry conferences and seminars.

- Read technical journals and publications.

- Participate in webinars and online learning platforms.

- Network with other quality control professionals.

- Stay informed about new industry standards and regulations.

9. Explain your experience in working with cross-functional teams to improve quality?

Answer:

- Successfully collaborated with engineering, production, and management teams to implement quality improvement initiatives.

- Participated in cross-functional problem-solving groups to identify and address quality issues.

- Facilitated communication between different departments to ensure alignment on quality goals and objectives.

- Leveraged team-based approaches to develop and implement innovative quality solutions.

10. How do you measure the effectiveness of your quality control efforts?

Answer:

- Establish key performance indicators (KPIs) such as defect rates, customer satisfaction scores, and process efficiency.

- Regularly collect and analyze data to track progress towards quality goals.

- Use statistical techniques to determine the significance of improvements.

- Provide regular reports to stakeholders on the performance and impact of quality control initiatives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Quality Control Industrial Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Quality Control Industrial Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Quality Control Industrial Engineers are responsible for ensuring that products and processes meet quality standards. They work with engineers, production staff, and other departments to identify and resolve quality issues. Key job responsibilities include:

1. Develop and implement quality control plans

This involves setting quality standards, developing test procedures, and implementing inspection systems.

- Developing and implementing quality control plans to ensure that products meet customer specifications

- Conducting quality audits and inspections to identify and resolve quality issues

2. Conduct quality audits and inspections

This involves inspecting products and processes to ensure that they meet quality standards. They also investigate customer complaints and work to resolve any issues.

- Conducting quality audits and inspections to identify and resolve quality issues

- Investigating customer complaints and working to resolve any issues

3. Analyze data and identify trends

This involves collecting and analyzing data on product quality and identifying trends. They use this information to make recommendations for improvements to the quality control process.

- Analyzing data and identifying trends to make recommendations for improvements to the quality control process

- Developing and implementing quality improvement initiatives

4. Develop and implement quality improvement initiatives

This involves developing and implementing strategies to improve the quality of products and processes. They also work with other departments to ensure that quality is integrated into all aspects of the business.

- Developing and implementing quality improvement initiatives

- Working with other departments to ensure that quality is integrated into all aspects of the business

Interview Tips

To ace an interview for a Quality Control Industrial Engineer position, candidates should prepare thoroughly and demonstrate their knowledge and skills. Here are some interviewing preparation tips:

1. Research the company and the position

This will give you a good understanding of the company’s culture, values, and needs. It will also help you to tailor your answers to the specific position you are applying for.

- Research the company’s website, social media pages, and news articles

- Read the job description carefully and identify the key requirements

2. Prepare your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Prepare your answers to these questions in advance so that you can deliver them confidently and clearly.

- Practice answering common interview questions out loud

- Use the STAR method to answer behavioral questions

3. Be prepared to discuss your experience and skills

The interviewer will want to know about your experience and skills in quality control. Be prepared to discuss your knowledge of quality control principles and practices, as well as your experience in developing and implementing quality control plans. You should also be able to demonstrate your analytical and problem-solving skills.

- Highlight your experience in developing and implementing quality control plans

- Share examples of how you have used analytical and problem-solving skills to improve quality

4. Be enthusiastic and professional

The interviewer will be looking for someone who is enthusiastic about quality control and who is passionate about their work. Be sure to convey your interest in the position and your commitment to quality.

- Dress professionally and arrive on time for your interview

- Be polite and respectful to everyone you meet

Next Step:

Now that you’re armed with the knowledge of Quality Control Industrial Engineer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Quality Control Industrial Engineer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini