Feeling lost in a sea of interview questions? Landed that dream interview for Quality Controller but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Quality Controller interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

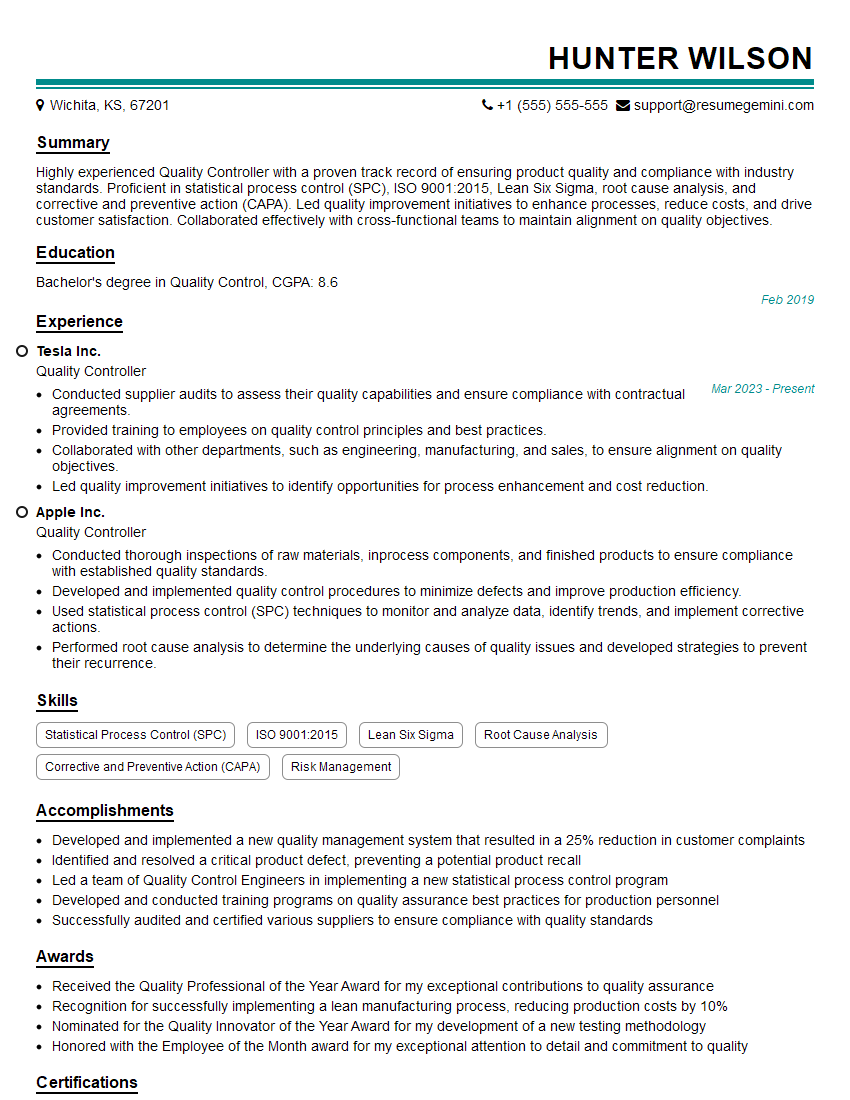

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Quality Controller

1. Explain the role and responsibilities of a Quality Controller in a manufacturing environment.

In the manufacturing domain, a Quality Controller has a crucial role in ensuring the quality and compliance of products. Their responsibilities include:

- Developing and implementing quality control plans and procedures

- Conducting inspections and tests on raw materials, in-process products, and finished goods

- Analyzing and interpreting test results to identify defects and non-conformances

- Initiating corrective and preventive actions to address quality issues

2. Describe the different types of quality control tools and techniques used in manufacturing.

Statistical Process Control (SPC)

- Using statistical methods to monitor and control production processes

- Identifying and correcting process variations to prevent defects

Acceptance Sampling

- Inspecting a sample of finished goods to determine the quality of the entire lot

- Using statistical tables to make decisions about accepting or rejecting the lot

3. Explain the importance of quality control in product development.

Quality control plays a vital role in product development by:

- Ensuring that products meet customer specifications and expectations

- Identifying and mitigating potential product defects

- Reducing the risk of product recalls and customer dissatisfaction

- Improving product reliability and performance

4. Describe the different types of quality control systems used in manufacturing.

- ISO 9001: An international standard that sets out requirements for quality management systems

- Six Sigma: A methodology focused on continuous improvement and reducing defects

- Lean Manufacturing: A system that focuses on eliminating waste and improving efficiency

5. Describe the role of Quality Control in Lean Manufacturing.

In a Lean environment, Quality Control is essential for:

- Identifying and eliminating waste in the production process

- Improving quality and reducing defects by focusing on root causes

- Ensuring that products meet customer specifications and expectations

6. Explain how Quality Control contributes to customer satisfaction.

Quality Control contributes to customer satisfaction by:

- Ensuring that products meet customer requirements

- Reducing defects and improving product reliability

- Providing customers with high-quality products and services

- Building customer trust and loyalty

7. Describe the importance of quality control in regulatory compliance.

Quality control is crucial for regulatory compliance as it ensures that products meet industry standards and government regulations. It helps companies to:

- Avoid fines and legal liabilities

- Protect public health and safety

- Maintain a positive reputation

8. Explain how you would use data analysis to improve product quality.

I would use data analysis to improve product quality by:

- Identifying trends and patterns in quality data

- Finding root causes of defects and non-conformances

- Developing and implementing corrective and preventive actions

- Tracking progress and making adjustments as needed

9. Describe your experience in using quality control software.

I have experience using various quality control software, including:

- Statistical Process Control (SPC) software

- Acceptance sampling software

- Defect tracking software

I am proficient in using these software to perform quality control tasks such as:

- Creating and managing control charts

- Performing acceptance sampling

- Tracking and analyzing defects

10. Describe your approach to quality improvement.

My approach to quality improvement is based on the following principles:

- Continuous improvement: Continuously identify areas for improvement and implement solutions

- Root cause analysis: Find the root causes of problems and address them at the source

- Data-driven decision-making: Use data to make informed decisions about quality improvement initiatives

- Collaboration: Work with cross-functional teams to identify and implement solutions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Quality Controller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Quality Controller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Quality Controllers are responsible for ensuring that the products or services of a company meet certain quality standards. They play a crucial role in maintaining the reputation and customer satisfaction of a company.

1. Quality Assurance and Control

Quality Controllers are responsible for developing and implementing quality assurance and control plans.

- Establish and maintain quality standards for products and services.

- Conduct inspections and tests to ensure that products and services meet these standards.

2. Data Analysis and Reporting

Quality Controllers are responsible for collecting and analyzing data on product or service quality.

- Analyze data to identify trends and patterns.

- Report on quality performance to management.

3. Continuous Improvement

Quality Controllers are responsible for working with other departments to identify and implement ways to improve quality.

- Identify areas for improvement in quality.

- Develop and implement solutions to improve quality.

4. Customer Relations

Quality Controllers may be responsible for interacting with customers to resolve quality issues.

- Respond to customer complaints and inquiries.

- Work to resolve quality issues and improve customer satisfaction.

Interview Tips

Preparing for a Quality Control interview requires a combination of technical knowledge and interpersonal skills. Review the following tips and hacks to ace your interview:

1. Research the Company and the Role

Researching the company’s values, mission, and products or services will help demonstrate your interest and understanding of the role.

- Visit the company website, read industry news, and check their social media presence.

- Learn about the specific products or services the company offers and identify any quality-related challenges they may face.

2. Highlight Your Technical Skills and Experience

Quality Controllers need a strong foundation in quality assurance and control principles. Showcase your expertise in these areas:

- Emphasize your understanding of quality control methodologies, such as Six Sigma, ISO standards, and Lean manufacturing.

- Provide examples of how you have implemented quality control measures in previous roles.

3. Demonstrate Your Problem-Solving Abilities

Quality Controllers are often required to solve complex quality issues. Highlight your problem-solving skills and analytical thinking:

- Prepare examples of how you have identified and resolved quality problems.

- Describe your approach to data analysis and how you use it to improve quality.

4. Communicate Effectively

Quality Controllers need to be able to communicate effectively with both technical and non-technical audiences. Emphasize your communication skills:

- Demonstrate your ability to clearly explain quality control concepts and processes.

- Provide examples of how you have successfully communicated with customers or other stakeholders about quality issues.

5. Be Prepared to Answer Common Interview Questions

Review common interview questions and practice your responses. This will help you feel more confident and prepared during the interview:

- Tell me about a time you had to resolve a complex quality issue.

- How do you stay up-to-date on the latest quality control trends and developments?

- What are your strengths and weaknesses as a Quality Controller?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Quality Controller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!