Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Quarry Plant Crusher Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Quarry Plant Crusher Operator so you can tailor your answers to impress potential employers.

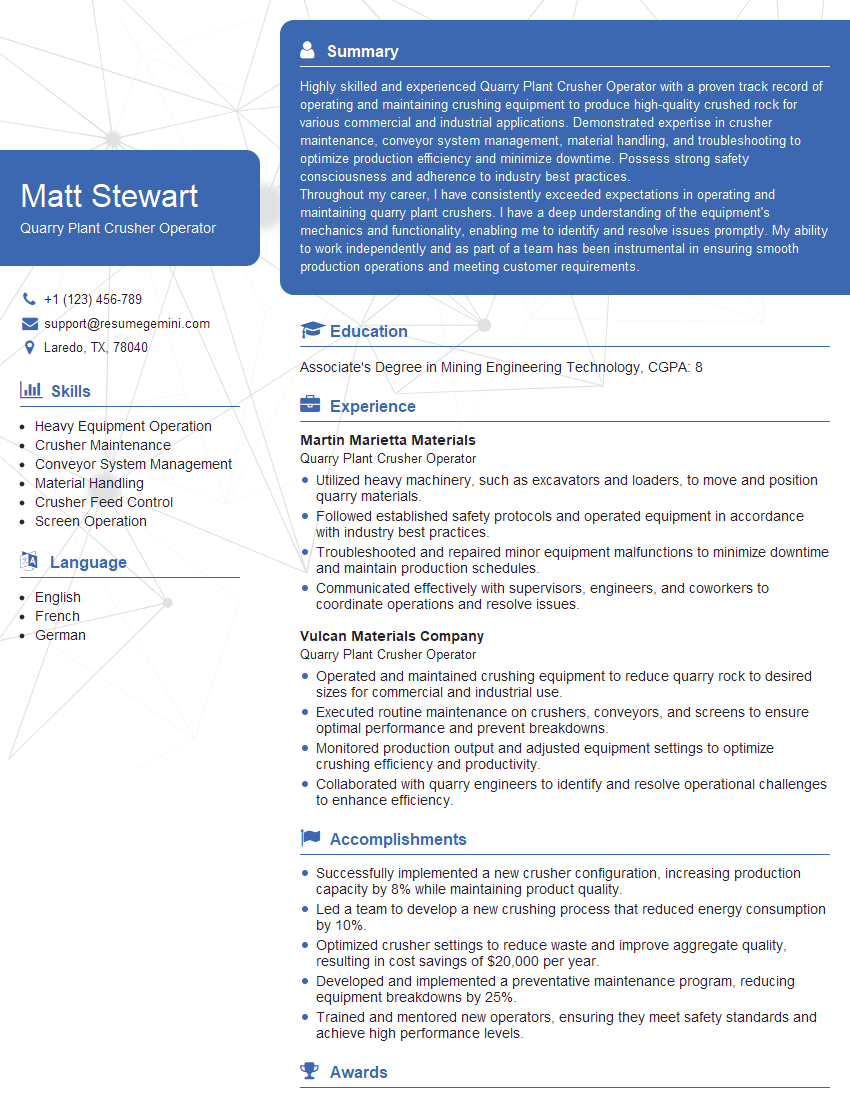

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Quarry Plant Crusher Operator

1. What are the key responsibilities of a Quarry Plant Crusher Operator?

As a Quarry Plant Crusher Operator, my primary responsibilities include:

- Operating and maintaining crushing and screening equipment to process quarry materials.

- Monitoring equipment performance, troubleshooting and resolving operational issues.

2. Describe the different types of crushers used in a quarry operation?

There are various types of crushers used in quarry operations, including:

Jaw crushers:

- Used for primary crushing of large rocks.

- Employs two opposing jaws to crush materials.

Cone crushers:

- Used for secondary and tertiary crushing.

- Features a cone-shaped head that rotates inside a stationary bowl.

3. How do you ensure the quality of the crushed materials produced?

To ensure the quality of crushed materials, I follow these steps:

- Regularly calibrating and maintaining equipment according to manufacturer specifications.

- Monitoring the feed rate and product size distribution.

- Conducting routine quality control tests, such as sieve analysis and moisture content determination.

4. What is the importance of proper lubrication in crusher maintenance?

Proper lubrication is crucial in crusher maintenance for several reasons:

- Reduces friction and wear on moving parts.

- Prevents overheating and premature equipment failure.

- Extends the lifespan of critical components.

5. Can you describe the safety precautions you take while operating crushing and screening equipment?

My top priority is ensuring safety in my operations. I adhere to the following precautions:

- Wearing appropriate personal protective equipment (PPE), including earplugs, safety glasses, and a hard hat.

- Following established lockout/tagout procedures during maintenance and repairs.

- Maintaining a clean and organized work area.

6. How do you handle potential equipment malfunctions or breakdowns?

In the event of equipment malfunctions or breakdowns, I take the following steps:

- Safely shut down the equipment.

- Identify the issue using troubleshooting techniques.

- Perform necessary repairs or contact maintenance personnel if required.

7. What is your experience with optimizing crusher performance to increase productivity?

I have experience in optimizing crusher performance through:

- Adjusting crusher settings to achieve desired product size and gradation.

- Monitoring feed rates to prevent overloading and underfeeding.

- Regularly cleaning and servicing equipment to minimize downtime.

8. How do you maintain accurate records of crusher operations and maintenance activities?

I keep meticulous records of all crusher operations and maintenance activities, including:

- Equipment inspections and calibrations.

- Production logs and quality control test results.

- Maintenance schedules and repairs performed.

9. What is your approach to working as part of a team in a quarry operation?

I am an effective team player who values collaboration and open communication.

- I actively share information and expertise with colleagues.

- I am always willing to assist others and support the team’s goals.

10. Describe your experience in using software applications for crusher monitoring and control.

I have experience using the following software applications:

- SCADA (Supervisory Control and Data Acquisition) systems for monitoring and controlling crusher operations.

- Maintenance management software for tracking equipment maintenance schedules and repairs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Quarry Plant Crusher Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Quarry Plant Crusher Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Quarry Plant Crusher Operator plays a crucial role in the quarrying process, operating heavy machinery to crush rocks and produce aggregate materials. Key responsibilities include:

1. Crusher Operation

Operate various types of crushing equipment, including jaw crushers, cone crushers, and impact crushers.

- Monitor crusher settings and adjust as necessary to optimize production.

- Troubleshoot and resolve operational issues to ensure smooth functioning of the quarry plant.

2. Raw Material Loading

Load raw materials, such as rocks and boulders, into the crusher using heavy-duty equipment like front-end loaders.

- Ensure proper loading practices to prevent blockages and equipment damage.

- Monitor material flow to maintain a consistent feed rate into the crusher.

3. Aggregate Sizing and Blending

Control the sizing and blending of crushed aggregates to meet customer specifications.

- Adjust crusher settings and blend different grades of aggregates to achieve desired particle sizes.

- Monitor aggregate quality using sampling and testing procedures.

4. Plant Maintenance

Contribute to the maintenance and upkeep of the crushing plant, ensuring its efficient operation.

- Perform routine inspections and maintenance tasks on equipment.

- Report any equipment issues or potential hazards to the supervisor promptly.

Interview Tips

To ace an interview for a Quarry Plant Crusher Operator position, it’s essential to effectively convey your relevant skills and experience. Here are some tips:

1. Highlight Your Heavy Machinery Experience

Emphasize your experience in operating heavy machinery, particularly crushing equipment. Describe your expertise in controlling crushers, monitoring settings, and troubleshooting operational issues.

- Example Outline: “I have extensive experience operating jaw crushers and cone crushers in a quarry setting. I can effectively monitor and adjust crusher settings to optimize production and ensure the production of aggregate materials meeting customer specifications.”

2. Demonstrate Your Knowledge of Aggregate Production

Showcase your understanding of the aggregate production process, including raw material loading, aggregate sizing, and blending. Explain how you maintain consistent material flow and achieve desired particle sizes.

- Example Outline: “I am proficient in loading raw materials into crushers using front-end loaders. I ensure proper loading practices to prevent blockages and maximize crusher efficiency. Additionally, I can control the sizing and blending of crushed aggregates to meet customer specifications.”

3. Emphasize Your Safety Consciousness

Quarry work involves heavy machinery and potential hazards. Highlight your commitment to safety by describing your experience in maintaining a safe working environment.

- Example Outline: “Safety is of utmost importance to me. I always wear appropriate safety gear and follow established safety protocols. I am also trained in hazard identification and control measures, and I actively participate in safety meetings and training sessions.”

4. Show Your Passion for the Industry

Express your enthusiasm for the quarry industry and your interest in operating crushing equipment. Explain how your skills and experience align with the company’s goals and the specific role.

- Example Outline: “I am passionate about the quarry industry and have always been fascinated by the process of crushing rocks and producing aggregate materials. I believe my skills and experience would make me a valuable asset to your team.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Quarry Plant Crusher Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!