Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Quencher Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

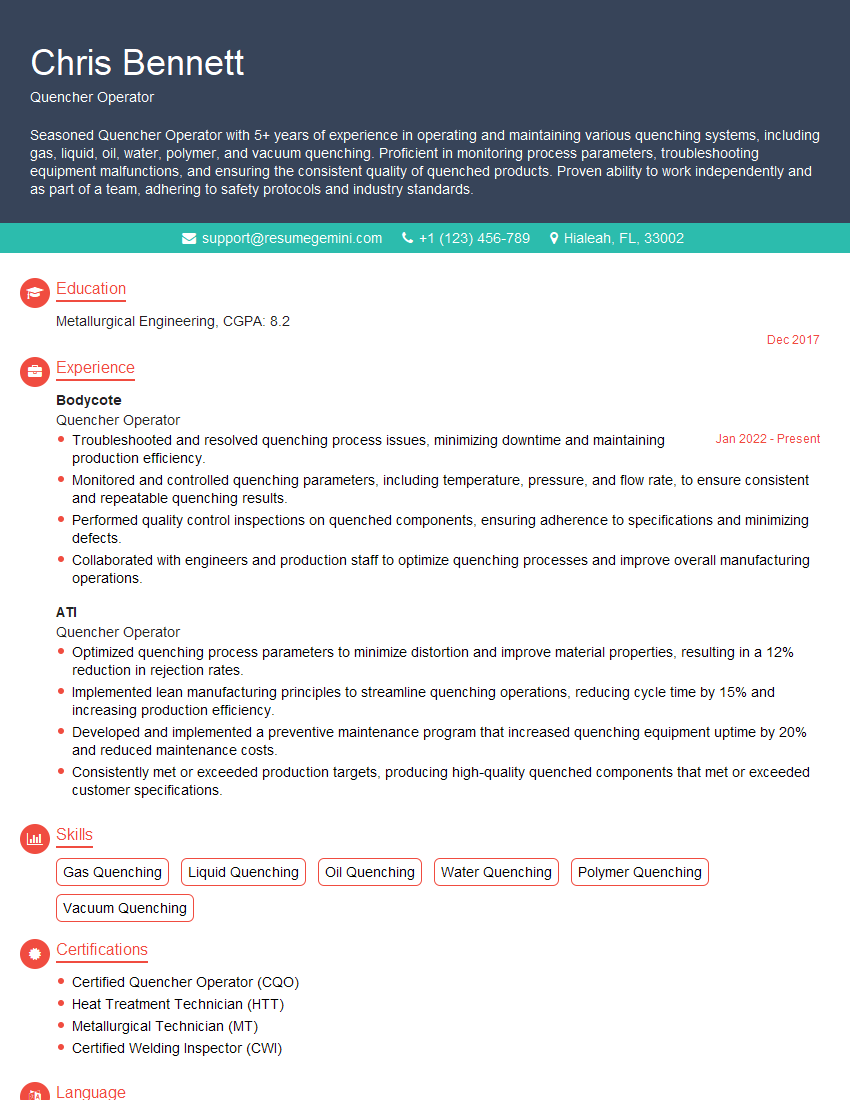

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Quencher Operator

1. Explain the process of quenching in metallurgy and its importance?

- Quenching is a heat treatment process that involves rapidly cooling a metal to obtain certain material properties.

- It is used to increase the hardness, strength, and wear resistance of metals.

- Rapid cooling prevents the formation of a crystalline structure and results in a martensitic or bainitic structure, which is harder and stronger than the original material.

2. Describe the different quenching methods and their applications?

Water Quenching

- Immersion in water for rapid cooling rates, resulting in high hardness.

- Used for small parts with simple shapes to minimize distortion.

Oil Quenching

- Immersion in oil for slower cooling rates compared to water quenching.

- Suitable for parts with complex shapes or larger sizes to reduce the risk of cracking.

Gas Quenching

- Use of inert gases like nitrogen or argon for cooling.

- Provides precise control over cooling rates and minimizes distortion.

Air Quenching

- Cooling in still air at room temperature.

- Used for parts that are not suitable for other quenching methods due to size or shape.

3. What are the factors that affect the effectiveness of quenching?

- Quenching medium (water, oil, gas, air)

- Agitation of the quenching medium

- Temperature of the quenching medium

- Size and shape of the part being quenched

- Composition of the metal being quenched

4. How do you determine the optimal quenching temperature for a specific metal?

- Refer to heat treatment charts or metallurgical data.

- Conduct experiments to determine the temperature that produces the desired properties.

5. What are the potential risks associated with quenching and how can they be mitigated?

Risks

- Quenching cracks due to uneven cooling or improper handling.

- Hydrogen embrittlement in certain metals due to the absorption of hydrogen during quenching.

Mitigation

- Use appropriate quenching methods and equipment.

- Control cooling rates carefully.

- Tempering after quenching to relieve stresses and reduce brittleness.

6. Explain the role of tempering after quenching?

- Tempering is a heat treatment process that follows quenching and involves heating the metal to a specific temperature below the critical temperature and then cooling it slowly.

- It reduces internal stresses caused by quenching, improves toughness, and enhances the ductility of the metal.

7. Describe the different types of quenching equipment and their applications?

Continuous Quenching Lines

- Automated systems that move parts through a series of quenching stages.

- Used for high-volume production of small parts.

Batch Quenching Tanks

- Tanks filled with quenching medium where parts are immersed manually.

- Suitable for small to medium-sized production runs.

Spray Quenching

- Systems that spray quenching medium onto the parts.

- Used for parts with complex shapes or where uniform cooling is required.

8. How do you maintain the quality of quenching media and ensure its effectiveness?

- Monitor and adjust the temperature of the quenching medium.

- Filter or replace the quenching medium regularly to remove contaminants.

- Control agitation of the quenching medium to ensure uniform cooling.

- Conduct regular tests to verify the quenching properties of the medium.

9. What safety precautions should be taken when operating quenching equipment?

- Wear appropriate personal protective equipment (PPE).

- Follow proper handling and storage procedures for quenching media.

- Ensure proper ventilation to prevent exposure to hazardous fumes.

- Be aware of potential explosion hazards with volatile quenching media.

10. Describe your experience with troubleshooting quenching problems?

Example Outline

- Describe a specific quenching problem you encountered.

- List the steps you took to troubleshoot the problem.

- Explain how you identified the root cause of the problem.

- Describe the solution you implemented to resolve the problem.

- Quantify the results of your troubleshooting efforts (e.g., reduced scrap rate, improved part quality).

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Quencher Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Quencher Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Quencher Operators play a crucial role in metalworking and heat treatment processes. Their key responsibilities include:

1. Operating Quenching Equipment

Quencher Operators are responsible for the safe and efficient operation of quenching equipment. This involves setting up, operating, and maintaining quench tanks, spray systems, and other related equipment.

2. Preparing and Maintaining Quenching Solutions

They prepare and maintain quenching solutions to meet specific requirements. This includes monitoring solution concentration, temperature, and agitation to ensure proper quenching results.

3. Heat Treating Metal Parts

Quencher Operators follow established procedures to heat treat metal parts by quenching them in a controlled environment. They ensure that parts are heated to the appropriate temperature and quenched at the optimal rate to achieve desired properties.

4. Monitoring Quenching Process

They monitor the quenching process to ensure it meets specifications. They observe the behavior of metal parts during quenching, adjusting process parameters as needed to achieve desired outcomes.

Interview Tips

To ace an interview for a Quencher Operator position, candidates should prepare thoroughly:

1. Research the Company and Role

Research the company’s industry, products or services, and the specific requirements of the Quencher Operator role. This shows that you’re interested in the position and the company culture.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating quenching equipment, preparing and maintaining quenching solutions, and heat treating metal parts. Share specific examples that demonstrate your proficiency.

3. Understand Quenching Principles

Demonstrate your understanding of quenching principles, including the effects of cooling rate on metal properties. Explain how you ensure the correct quenching process for different materials.

4. Emphasize Safety and Quality

Highlight your commitment to safety and quality control. Explain how you follow established protocols to maintain equipment and ensure the integrity of quenched parts.

5. Practice Example Questions

Prepare answers to common interview questions such as “Describe a time you solved a problem on the job,” “Why are you interested in this role,” and “What are your strengths and weaknesses.”

6. Prepare Technical Questions

Prepare questions about the specific quenching processes used at the company and how you can contribute to their operations. This shows your interest in the company’s technical capabilities.

7. Dress Professionally and Arrive Punctually

Arrive for the interview on time, dressed professionally. This demonstrates your punctuality and respect for the interviewer’s time.

8. Ask Questions

At the end of the interview, ask thoughtful questions about the company’s culture, career growth opportunities, and any specific challenges related to the role. This shows that you’re engaged and interested in the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Quencher Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Quencher Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.