Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Quenching Car Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

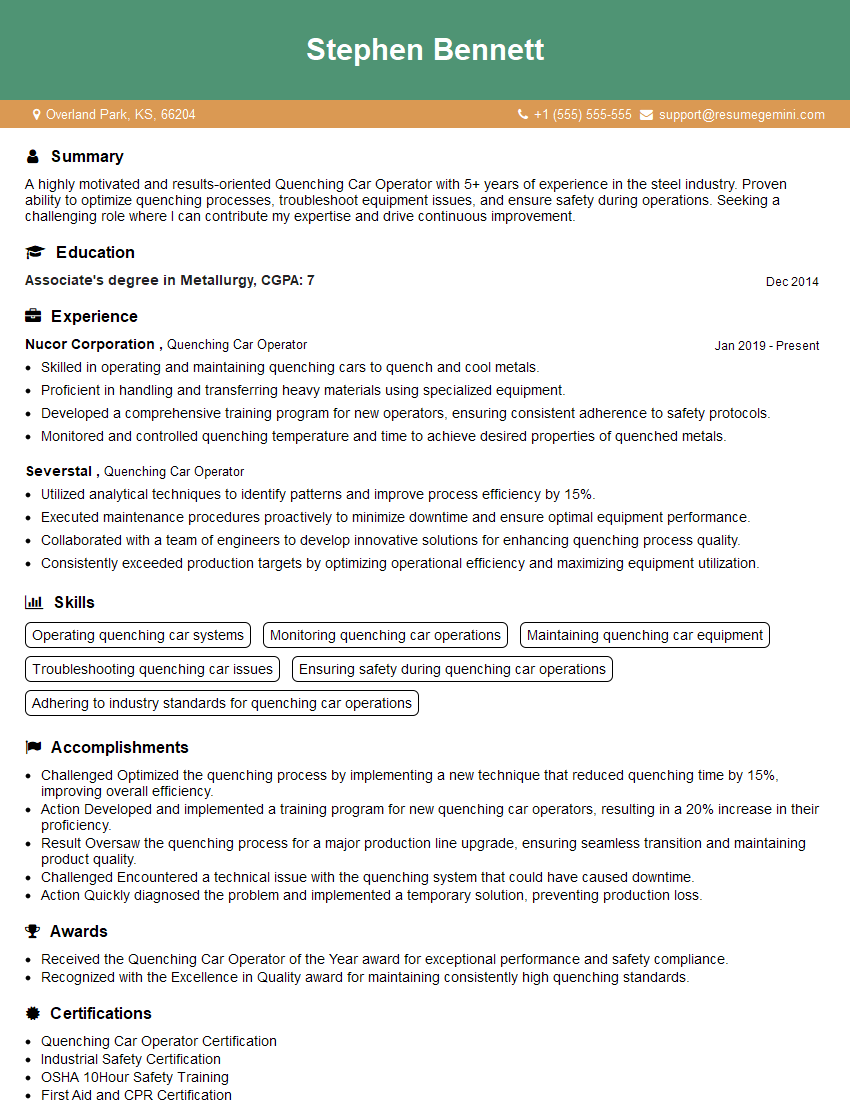

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Quenching Car Operator

1. Explain the process of quenching in detail?

Quenching is a heat treatment process that involves rapidly cooling a metal to obtain the desired properties, such as hardness and strength. It is commonly used to harden steel and other alloys.

- The process begins by heating the metal to a specific temperature, called the quenching temperature. This temperature varies depending on the type of metal and the desired properties.

- The heated metal is then rapidly cooled in a quenching medium, such as water, oil, or salt baths. The cooling rate must be fast enough to prevent the formation of unwanted phases or structures in the metal.

- The rate of cooling affects the final properties of the metal. Faster cooling rates result in harder and stronger materials, while slower cooling rates produce softer and more ductile materials.

2. What are the different types of quenching media?

- Water: Water is the most common and fastest quenching medium. It is used for high-strength steels and other metals that require rapid cooling rates.

- Oil: Oil is a less severe quenching medium than water, but it can still achieve high hardness levels. It is often used for medium-carbon steels and other alloys that are prone to cracking.

- Salt baths: Salt baths are used for quenching at specific temperatures. They provide a more controlled cooling rate and can be used for a variety of metals, including aluminum, copper, and titanium.

3. What factors affect the choice of quenching medium?

- The type of metal: Different metals have different quenching requirements. Some metals, such as steel, require rapid cooling rates to achieve high hardness, while other metals, such as aluminum, can tolerate slower cooling rates.

- The desired properties: The choice of quenching medium can affect the final properties of the metal. Faster cooling rates result in harder and stronger materials, while slower cooling rates produce softer and more ductile materials.

- The geometry of the part: The shape and size of the part can affect the choice of quenching medium. Large or complex parts may require slower cooling rates to prevent cracking.

4. What are the safety precautions that should be taken when quenching?

- Wear appropriate protective gear: This includes safety glasses, gloves, and a lab coat.

- Ensure proper ventilation: Quenching can generate fumes and vapors, so it is important to have good ventilation in the area.

- Handle hot objects with care: Use tongs or gloves to move hot metals and avoid touching them directly.

- Be aware of fire hazards: Quenching in oil can create a fire hazard, so it is important to have a fire extinguisher nearby.

5. How do you maintain the quenching equipment?

- Regularly clean the quench tank: Remove any debris or contaminants from the quench tank to ensure proper heat transfer and prevent contamination of the metal.

- Inspect the quench medium: Regularly check the quench medium for contamination or degradation. Replace the quench medium as needed to maintain its effectiveness.

- Calibrate the temperature control system: Ensure that the temperature control system is accurate and properly calibrated to achieve the desired quenching temperature.

- Maintain the agitator: The agitator helps to circulate the quench medium and ensure uniform cooling. Regularly inspect and maintain the agitator to ensure its proper operation.

6. What are the common defects that can occur during quenching?

- Cracking: Cracking can occur if the cooling rate is too fast or if the part is not properly supported.

- Warping: Warping can occur if the part is not evenly cooled or if it is not properly supported.

- Soft spots: Soft spots can occur if the part is not quenched properly or if the quench medium is not effective.

7. How do you troubleshoot quenching problems?

- Identify the problem: Determine the specific problem that is occurring, such as cracking, warping, or soft spots.

- Check the quenching parameters: Verify that the quenching temperature, cooling rate, and quench medium are correct for the type of metal and the desired properties.

- Inspect the part: Examine the part for any defects, such as cracks or warpage. This can help to identify the cause of the problem.

- Adjust the quenching process: Make necessary adjustments to the quenching parameters or the quenching equipment to resolve the problem.

8. Describe the role of tempering after quenching?

- Tempering is a heat treatment process that is performed after quenching to reduce the hardness and increase the toughness of the metal.

- Tempering involves heating the quenched metal to a specific temperature below the quenching temperature and then cooling it slowly.

- The tempering temperature and the cooling rate affect the final properties of the metal.

9. Explain the difference between through-hardening and case-hardening?

- Through-hardening: Through-hardening involves heating the entire part to the quenching temperature and then cooling it rapidly to achieve uniform hardness throughout the part.

- Case-hardening: Case-hardening involves heating only the surface of the part to the quenching temperature and then cooling it rapidly. This process results in a hard surface and a softer core.

10. What are the quality control procedures for quenching?

- Hardness testing: Hardness testing is performed to verify that the desired hardness level has been achieved.

- Dimensional inspection: Dimensional inspection is performed to ensure that the part meets the specified dimensions and tolerances.

- Visual inspection: Visual inspection is performed to identify any defects, such as cracks or warpage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Quenching Car Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Quenching Car Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Quenching Car Operators play a crucial role in the manufacturing industry, primarily responsible for overseeing the quenching process of metal components. They ensure that the components undergo proper heat treatment to achieve desired hardness and strength.

1. Quenching Operations

Quenching Car Operators are entrusted with operating quenching cars that carry heated metal components into a quenching medium, such as oil, water, or gas. They control the temperature, flow rate, and duration of the quenching process to achieve specific material properties.

- Manage the quenching car and ensure its smooth operation.

- Monitor and adjust the quenching parameters (temperature, flow rate, duration) to meet specifications.

2. Material Handling

They are responsible for handling and moving metal components before, during, and after the quenching process. They must ensure proper handling techniques to prevent damage or injury.

- Load and unload metal components from quenching cars and other equipment.

- Inspect components for any defects or damage before and after quenching.

3. Equipment Maintenance

Quenching Car Operators are expected to perform routine maintenance and cleaning of quenching equipment. They play a vital role in ensuring the safe and efficient operation of machines.

- Clean and maintain quenching cars, tanks, and other equipment.

- Monitor equipment performance and report any issues or malfunctions promptly.

4. Safety and Quality Control

They are responsible for adhering to safety protocols and ensuring the quality of quenched components. They follow established procedures and monitor the process closely to guarantee the end products meet specifications.

- Wear appropriate personal protective equipment (PPE) and follow safety guidelines.

- Inspect quenched components for quality and ensure they meet the required standards.

Interview Tips

Preparing for an interview for a Quenching Car Operator position requires thorough research and a well-structured approach. Here are some essential tips to help you ace the interview:

1. Research the Company and Role

Take the time to research the company and the specific role you’re applying for. Understanding their industry, values, and the job requirements will help you tailor your answers and demonstrate your suitability.

- Visit the company website and social media pages to gather information.

- Read industry publications and articles to stay informed about the latest trends.

2. Practice Common Interview Questions

Familiarize yourself with common interview questions related to the role and industry. Prepare thoughtful and concise answers that highlight your skills, experience, and knowledge.

- Tell me about your experience operating quenching cars?

- How do you ensure the quality and accuracy of the quenching process?

3. Emphasize Safety and Attention to Detail

Safety and attention to detail are crucial for Quenching Car Operators. Highlight your commitment to following safety protocols, including wearing PPE and adhering to established procedures.

- Share examples of how you have proactively identified and addressed safety concerns.

- Explain your methods for ensuring accuracy and precision in handling and processing components.

4. Demonstrate Problem-Solving Abilities

Interviewers want to know that you can handle potential challenges and think critically. Showcase your problem-solving skills by providing examples of how you have resolved issues related to equipment malfunctions, process deviations, or quality concerns.

- Describe a situation where you identified and resolved a problem with quenching equipment.

- Explain how you handled a deviation in the quenching process and ensured the quality of the end product.

5. Be Enthusiastic and Professional

Show your enthusiasm for the role and the industry. Be polite, respectful, and maintain a professional demeanor throughout the interview. Your attitude and communication skills play a significant role in creating a positive impression.

- Express your passion for the quenching process and the manufacturing industry.

- Dress appropriately and arrive on time for the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Quenching Car Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!