Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Quenching Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

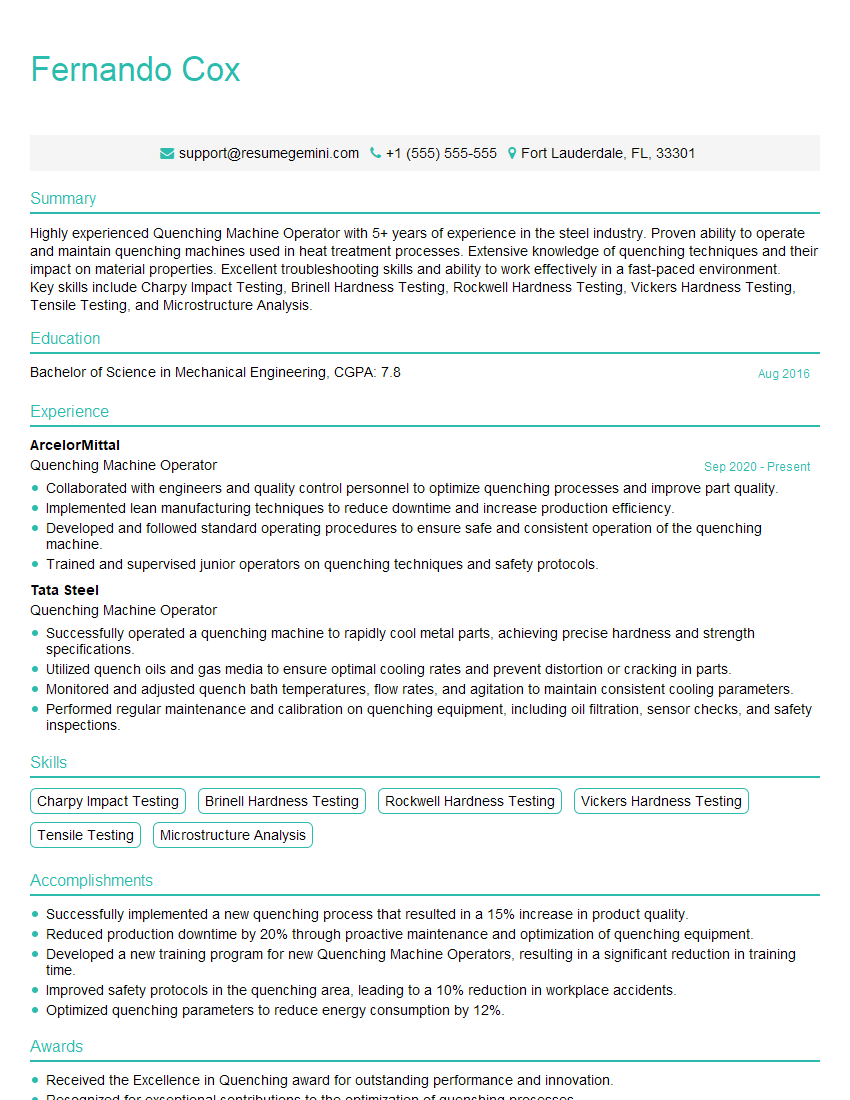

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Quenching Machine Operator

1. Describe the process of quenching?

Quenching is a heat treatment process that involves rapidly cooling a metal to obtain a harder material with a finer grain structure. The process involves heating the metal to a specific temperature, holding it at that temperature for a specific period, and then rapidly cooling it by immersing it in a quenching medium such as water, oil, or a gas.

2. What are the different types of quenching media?

- Water: Provides the fastest cooling rate, resulting in a harder material with higher strength and wear resistance.

- Oil: Provides a slower cooling rate than water, resulting in a more ductile material with lower strength but improved toughness.

- Gas: Provides the slowest cooling rate, resulting in a material with the lowest strength but the highest toughness.

3. What are the variables that affect the quenching process?

- Temperature of the metal before quenching

- Holding time at the quenching temperature

- Rate of cooling during quenching

- Type of quenching medium

- Agitation of the quenching medium

4. What are the benefits of quenching?

- Increased hardness and wear resistance

- Improved strength and toughness

- Refined grain structure

- Altered electrical and magnetic properties

5. What are the potential risks of improper quenching?

- Cracking due to rapid cooling

- Warping due to uneven cooling

- Soft spots due to incomplete quenching

- Reduced ductility due to excessive quenching

6. How do you monitor and control the quenching process to ensure consistent results?

- Using temperature sensors to monitor the temperature of the metal and quenching medium

- Using timers to control the holding time at the quenching temperature

- Using agitation devices to ensure uniform cooling

- Conducting hardness tests to verify the effectiveness of the quenching process

7. Describe the safety precautions that must be taken when operating a quenching machine?

- Wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs

- Ensuring that the quenching machine is properly grounded and maintained

- Handling hot metal with caution and using proper handling equipment

- Being aware of potential hazards such as splashing quenching medium, steam, and sparks

8. How do you troubleshoot common problems that may occur during the quenching process?

- Cracking: Adjust cooling rate, temperature, or agitation.

- Warping: Use fixturing or adjust cooling method.

- Soft spots: Increase quenching time or temperature.

- Reduced ductility: Reduce quenching severity or use a more suitable quenching medium.

9. What is your experience with different types of quenching machines?

I have experience operating a variety of quenching machines, including water-based, oil-based, and gas-based systems. I am familiar with the different types of controls, safety features, and maintenance requirements for each type of machine.

10. How do you stay updated on the latest advancements in quenching technology?

- Attending industry conferences and workshops

- Reading technical journals and articles

- Consulting with experts in the field

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Quenching Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Quenching Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Quenching Machine Operator, you will undertake the following responsibilities:

1. Operation of Quenching Machine

Set up, operate, and maintain quenching machines to cool and harden metal parts.

- Adjusting machine settings, such as temperature, pressure, and speed, to achieve desired results.

- Monitoring the quenching process to ensure parts meet specifications.

2. Part Preparation and Handling

Prepare and handle metal parts for quenching.

- Inspecting parts for defects and ensuring they are properly cleaned and preheated.

- Loading and unloading parts from the quenching machine.

3. Quality Control

Ensure the quality of quenched parts.

- Performing visual inspections and using testing equipment to verify the hardness and other properties.

- Adhering to quality standards and procedures.

4. Equipment Maintenance

Maintain and troubleshoot quenching equipment.

- Performing routine maintenance tasks, such as cleaning and lubrication.

- Identifying and resolving equipment malfunctions.

Interview Tips

To ace your interview for the Quenching Machine Operator position, consider the following tips:

1. Research the Company and Role

Take the time to learn about the company’s history, products/services, and industry. Understanding the company’s culture and values will help you tailor your answers and demonstrate your interest.

- Review the job description thoroughly to identify the key requirements and responsibilities.

- Think about how your skills and experience align with the position.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills and knowledge in operating quenching machines, part preparation, and quality control. Quantify your accomplishments whenever possible using specific examples.

- Describe your experience in setting up and operating different types of quenching machines.

- Explain how you have maintained the quality of quenched parts and ensured they meet specifications.

3. Demonstrate Problem-Solving Abilities

Interviewers often assess candidates’ problem-solving skills. Be prepared to share examples of how you have identified and resolved equipment malfunctions or quality issues related to quenching.

- Describe a situation where you encountered a problem and how you used your technical knowledge and troubleshooting skills to find a solution.

- Explain how you have implemented improvements to enhance the quenching process or equipment.

4. Show Safety Consciousness

Working with quenching machines involves potential safety hazards. Highlight your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Discuss your knowledge of safety regulations and best practices related to quenching operations.

- Share any experience you have in implementing or improving safety measures.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Quenching Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.