Are you gearing up for an interview for a Quill Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Quill Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

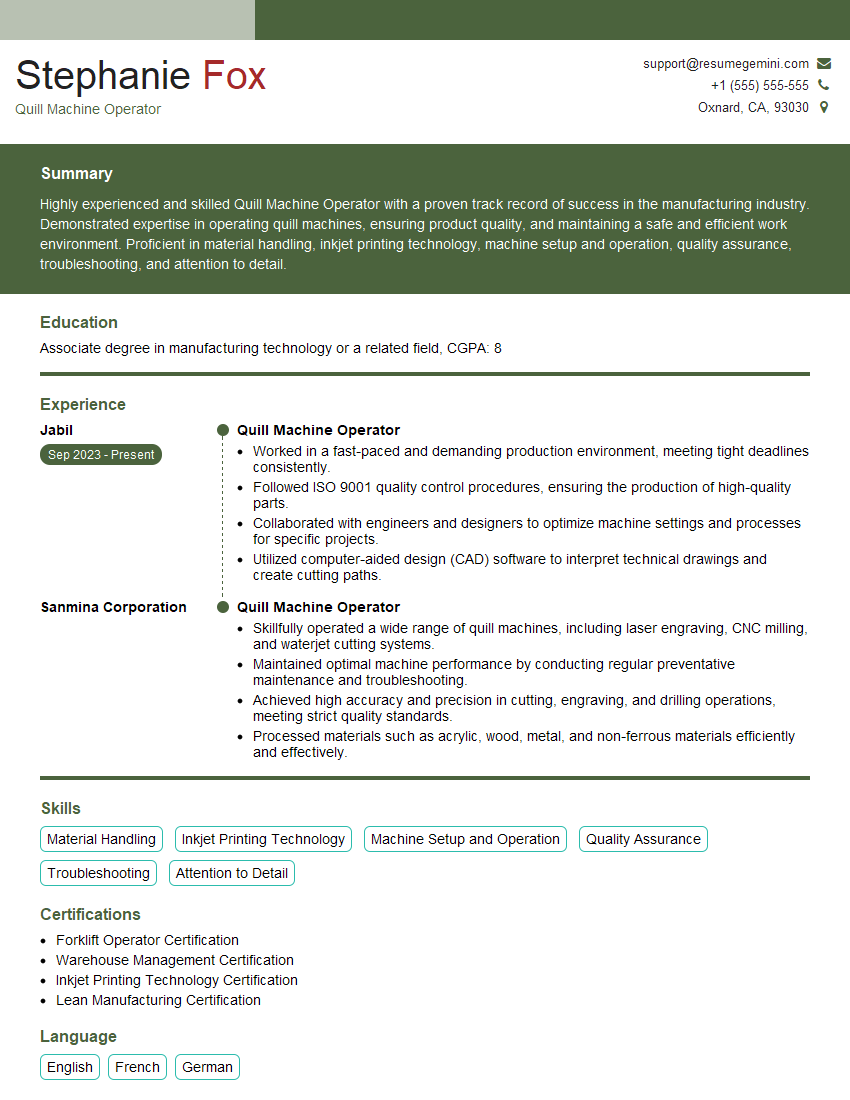

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Quill Machine Operator

1. What are the key responsibilities of a Quill Machine Operator?

As a Quill Machine Operator, I am responsible for operating and maintaining quill machines used in the production of various products. My primary duties include:

- Setting up and operating quill machines according to established procedures.

- Monitoring the machine’s performance and making necessary adjustments to ensure optimal operation.

- Inspecting raw materials and finished products to ensure quality standards are met.

- Following safety protocols and maintaining a clean and organized work area.

2. Explain the process of quill winding.

How to Quill Wind

- Select the appropriate quill size and type for the desired product.

- Prepare the raw material, such as yarn or thread, by unwinding it from the spool.

- Attach the raw material to the quill and secure it firmly.

- Start the quill machine and adjust the winding speed and tension settings.

- Monitor the winding process and make adjustments as needed to ensure proper winding.

Quality Control

- Inspect the wound quills for any defects or inconsistencies.

- Measure the quills to ensure they meet the specified dimensions and specifications.

- Label and store the quills appropriately for further processing or storage.

3. What are the different types of quill machines?

There are several types of quill machines, each designed for specific applications and products:

- Conventional quill machines: Used for winding yarn or thread onto quills for use in weaving or knitting.

- CNC quill machines: Computer-controlled machines that offer precise and automated winding processes.

- High-speed quill machines: Designed for high-volume production, these machines operate at faster speeds.

- Specialty quill machines: Used for winding specialized materials or creating unique effects on quills.

4. How do you troubleshoot common issues with quill machines?

Troubleshooting common issues with quill machines requires a combination of technical knowledge and practical experience:

- Yarn breakage: Check for tension issues, improper threading, or damaged yarn.

- Quill deformation: Ensure the quill is properly secured and the machine is operating within specified parameters.

- Uneven winding: Adjust the winding speed, tension, or yarn quality to achieve uniform winding.

- Machine malfunction: Follow established maintenance procedures and contact qualified technicians for repairs if necessary.

5. What are the safety precautions to follow when operating a quill machine?

Safety is paramount when operating quill machines. Key precautions include:

- Always wear appropriate safety gear, such as gloves and safety glasses.

- Keep the work area clean and free of tripping hazards.

- Never reach into the machine while it is running.

- Report any malfunctions or safety concerns promptly.

- Follow all established safety protocols and guidelines.

6. How do you maintain and calibrate a quill machine?

Regular maintenance and calibration are crucial for optimal quill machine performance:

- Daily maintenance: Clean the machine, check for loose parts, and lubricate as necessary.

- Weekly maintenance: Inspect and replace worn or damaged components, such as belts or bearings.

- Calibration: Regularly calibrate the machine using precision tools to ensure accuracy and consistency in winding.

- Records: Keep detailed records of maintenance and calibration procedures for traceability and quality control.

7. What is your experience with quality control in quill winding?

Quality control is a critical aspect of quill winding. My experience includes:

- Visual inspections: Examining wound quills for defects, unevenness, or other quality issues.

- Dimensional measurements: Verifying the dimensions and specifications of the quills using precision measuring instruments.

- Performance testing: Conducting tests to assess the strength, durability, and functionality of the wound quills.

- Data analysis: Analyzing quality control data to identify trends and areas for improvement.

8. Describe your knowledge of different types of yarns and their suitability for quill winding.

Understanding different yarn types is essential for optimizing quill winding processes:

- Natural fibers: Cotton, wool, silk, linen – Properties, strengths, and winding considerations.

- Synthetic fibers: Nylon, polyester, acrylic – Characteristics, advantages, and winding techniques.

- Blended yarns: Combinations of natural and synthetic fibers – Benefits, winding challenges, and applications.

- Specialty yarns: Metallic, elastic, textured – Unique properties and specialized winding requirements.

9. How do you handle production targets and deadlines?

Meeting production targets and deadlines requires effective time management and organization:

- Planning: Breaking down tasks, estimating timeframes, and prioritizing activities.

- Scheduling: Creating production schedules and adhering to them as closely as possible.

- Coordination: Collaborating with colleagues and supervisors to ensure smooth workflow.

- Flexibility: Adjusting schedules and re-prioritizing tasks as needed to meet deadlines.

- Problem-solving: Identifying and addressing potential bottlenecks or delays promptly.

10. What are your long-term career goals and how do you see this role contributing to them?

My long-term career goals align with the growth opportunities available in this role:

- Advancement: Aspiring to supervisory or managerial positions within the field.

- Expertise: Continuously developing my technical skills and becoming a subject matter expert in quill winding.

- Innovation: Contributing to the development and implementation of new techniques or technologies in the industry.

- Leadership: Inspiring and guiding others to achieve optimal performance and quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Quill Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Quill Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Quill Machine Operators are responsible for operating and maintaining quill machines, a specialized type of winding machine that produces coils for electric motors and transformers. They are an integral part of the manufacturing process, ensuring the quality and efficiency of the final product.

1. Machine Operation and Maintenance

Operate quill machines to wind coils for electric motors and transformers according to specified parameters.

- Monitor machine performance and adjust settings to optimize coil quality and output.

- Conduct routine maintenance and repairs to ensure smooth machine operation.

2. Quality Control

Inspect coils for defects and ensure compliance with quality standards.

- Utilize precision measuring instruments and visual inspection techniques.

- Identify and correct any deviations from specifications.

3. Production Monitoring and Reporting

Track production output and maintain accurate records.

- Monitor coil production rates and identify areas for improvement.

- Generate reports on production performance and quality.

4. Safety and Environment

Follow established safety protocols and maintain a clean and organized work environment.

- Wear appropriate personal protective equipment (PPE).

- Handle hazardous materials with care.

Interview Tips

To ace an interview for a Quill Machine Operator position, it’s crucial to prepare thoroughly and showcase your skills and experience.

1. Research the Company and Role

Familiarize yourself with the company’s background, values, and the specific requirements of the Quill Machine Operator role. This demonstrates your interest and enthusiasm.

- Visit the company website and social media pages.

- Read industry articles and online discussions.

2. Highlight Your Technical Skills and Experience

Emphasize your proficiency in operating and maintaining quill machines. Mention specific techniques and technologies you are familiar with.

- Provide examples of how you have optimized machine performance and improved coil quality.

- Discuss your experience in troubleshooting and resolving machine issues.

3. Showcase Your Quality Standards

Demonstrate your understanding of quality control procedures and your commitment to producing defect-free coils.

- Explain your approach to inspecting coils and identifying deviations from specifications.

- Describe any quality improvement initiatives you have participated in.

4. Prepare for Behavioral Questions

Be prepared to answer behavioral questions that assess your problem-solving abilities, teamwork skills, and commitment to safety.

- Use the STAR method (Situation, Task, Action, Result) to provide clear and concise responses.

- For example, describe a time when you identified a problem with a quill machine and took steps to resolve it.

5. Be Enthusiastic and Professional

Throughout the interview, maintain a positive attitude and show that you are genuinely interested in the role. Dress professionally and arrive on time.

- Express your enthusiasm for working in the manufacturing industry.

- Ask thoughtful questions to demonstrate your knowledge and interest in the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Quill Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.