Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Quill Winder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

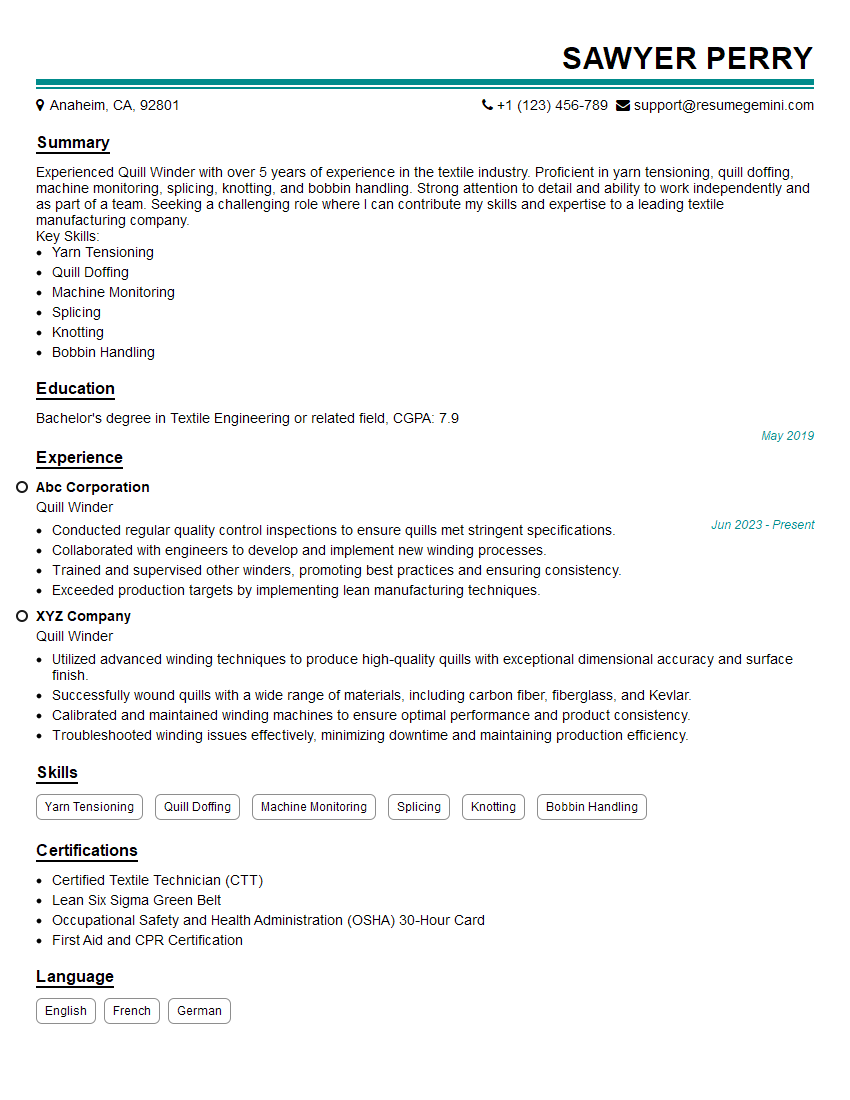

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Quill Winder

1. What are the key characteristics of a high-quality quill wind?

- Strong and flexible shaft made of goose, swan, or turkey feather.

- Sharp and pointed tip for precise writing.

- Appropriate curvature to allow smooth ink flow.

- Durable and long-lasting with proper maintenance.

- Aesthetically pleasing with natural variations and colorations.

2. How do you select the right type of feather for a quill wind?

Feather Characteristics:

- Goose feathers: Large, strong, and flexible, suitable for writing.

- Swan feathers: Smaller than goose feathers, softer and more delicate.

- Turkey feathers: Long and stiff, used for larger pens or decorative purposes.

Selection Criteria:

- Purpose of the quill (e.g., writing, calligraphy, drawing).

- Desired size and shape of the quill.

- Personal preference and experience with different feather types.

3. What are the steps involved in preparing a quill wind?

- Remove the feather from the bird (ethically sourced).

- Strip the feather to remove the quill shaft.

- Soften the shaft by soaking it in water or rubbing it with a cloth.

- Shape the shaft by cutting and trimming the tip.

- Split the tip to create a writing point.

- Cure the quill by drying it gradually to preserve its strength and flexibility.

4. How do you maintain a quill wind for optimal use?

- Clean the quill regularly with water or a mild soap solution.

- Store the quill in a dry and ventilated place.

- Sharpen the tip as needed using a quill knife or sand.

- Avoid exposing the quill to extreme temperatures or humidity.

- Handle the quill with care to prevent damage.

5. What are the advantages and disadvantages of using a quill wind over other writing instruments?

Advantages:

- Precision and control in writing.

- Unique and personalized writing experience.

- Aesthetic appeal and historical significance.

Disadvantages:

- Requires preparation and maintenance.

- Limited ink capacity compared to modern pens.

- Susceptible to damage or breakage.

6. How do you troubleshoot common problems with quill winds, such as scratching or skipping?

- Check the sharpness of the tip and sharpen it if necessary.

- Ensure the quill is not too dry or too wet.

- Check for any damage or defects in the quill.

- Try a different type of ink or paper.

- Allow the quill to rest occasionally to prevent overheating.

7. What are the different types of calligraphy scripts that can be written with a quill wind?

- Blackletter or Gothic Script: Angular and decorative script.

- Italic Script: Flowing and cursive script.

- Copperplate Script: Elegant and ornate script.

- Uncial Script: Ancient Roman script.

- Brush Script: Script that mimics the effects of a brush.

8. What are the essential materials and tools needed for quill winding?

- Fresh or dried feathers

- Quill knife or scalpel

- Tweezers

- Sandpaper or quill sharpener

- Ink and inkwell

- Paper

9. How do you store and transport quill winds safely?

- Keep quills in a dry and ventilated box or case.

- Protect the quills from moisture and extreme temperatures.

- Wrap quills individually in tissue paper to prevent damage.

- Handle quills with care to avoid breakage.

10. What are the ethical considerations terkait with quill winding?

- Emphasize the importance of sourcing feathers ethically.

- Discuss sustainable practices for feather harvesting.

- Respect for the birds and their habitat.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Quill Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Quill Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Quill Winder, also known as a Bobbin Winder, is responsible for operating machines that wind yarn onto quills or bobbins. These quills or bobbins are then used in weaving or knitting machines to create various fabrics and textiles.

1. Machine Operation

The primary responsibility of a Quill Winder is to operate and maintain quill winding machines. This involves:

- Setting up and calibrating the machine according to specific yarn and quill/bobbin requirements.

- Loading yarn onto the machine and ensuring proper tension and alignment.

- Monitoring the winding process and making adjustments as needed to ensure consistent and high-quality winding.

2. Quality Control

Quill Winders are also responsible for ensuring the quality of the wound quills or bobbins:

- Inspecting wound quills/bobbins for defects, such as uneven winding, broken threads, or contamination.

- Identifying and rectifying any issues with the winding process to minimize waste and maintain production efficiency.

3. Production Monitoring

Quill Winders are typically responsible for monitoring and maintaining production targets:

- Tracking the number of quills/bobbins produced per shift or day.

- Identifying and addressing any bottlenecks or production delays to maximize output.

4. Machine Maintenance

In addition to operating and monitoring machines, Quill Winders may also be involved in basic machine maintenance tasks, including:

- Cleaning and lubricating machines regularly to ensure smooth operation.

- Conducting minor repairs and troubleshooting common machine issues.

- Reporting any major maintenance needs to supervisors or maintenance personnel.

Interview Tips

Preparing for an interview as a Quill Winder requires candidates to showcase their technical skills, attention to detail, and ability to work in a production environment.

1. Research the Company and Role

Before the interview, research the company’s background, products, and industry standing. This demonstrates your interest in the role and organization.

- Visit the company’s website to learn about their products and values.

- Check industry news and reports to stay informed about the company’s position in the market.

2. Highlight Technical Skills

Emphasize your experience and proficiency in operating quill winding machines. Quantify your achievements whenever possible.

- Mention the types of machines you’ve operated, their capacities, and the materials you’ve handled.

- Provide specific examples of how you’ve improved winding efficiency or reduced downtime.

3. Demonstrate Attention to Detail

Quill Winders must be meticulous in their work. Highlight your ability to identify and rectify quality issues.

- Explain your quality control procedures and how you ensure the accuracy and consistency of your work.

- Describe instances where you identified and resolved winding defects, minimizing production errors.

4. Showcase Production Mindset

Quill Winders contribute to production targets. Demonstrate your understanding of production processes and your commitment to achieving goals.

- Discuss your experience in monitoring production rates and identifying areas for improvement.

- Explain how you’ve contributed to optimizing production lines and meeting deadlines.

5. Prepare for Common Interview Questions

Research common interview questions and prepare thoughtful answers that highlight your skills and experience.

- Tell me about your experience in operating quill winding machines.

- How do you ensure the quality of your work?

- How do you handle production delays or machine malfunctions?

- What are your strengths and weaknesses as a Quill Winder?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Quill Winder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.