Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Rabbet Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Rabbet Operator so you can tailor your answers to impress potential employers.

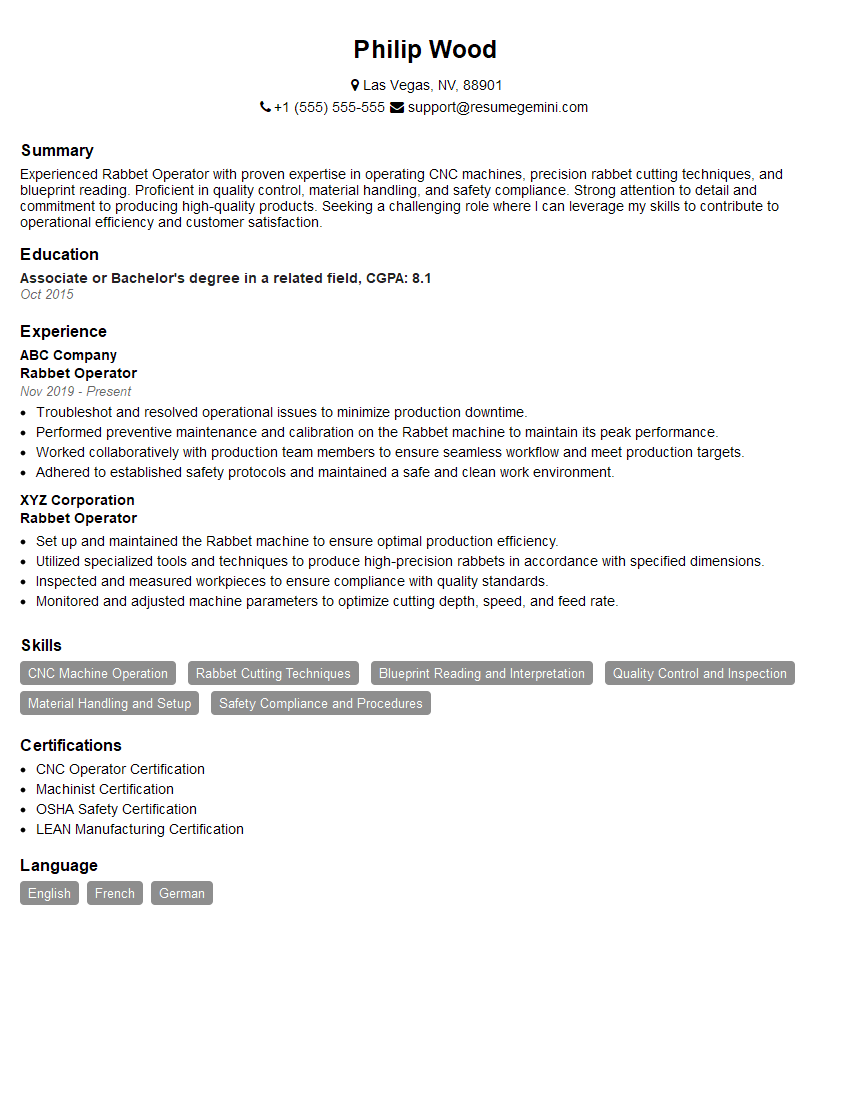

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rabbet Operator

1. What are the key responsibilities of a Rabbet Operator?

- Set up and operate rabbeting machines to cut rabbets in wood, plastic, or metal workpieces.

- Adjust machine settings to ensure rabbets are cut to the correct depth, width, and angle.

- Inspect workpieces to ensure they meet quality standards.

- Maintain and clean machines and work area.

- Follow safety procedures and wear appropriate personal protective equipment.

2. What are the different types of rabbeting machines?

Horizontal rabbeting machines

- Cut rabbets in the horizontal plane.

- Suitable for large workpieces or workpieces that cannot be easily rotated.

Vertical rabbeting machines

- Cut rabbets in the vertical plane.

- Suitable for smaller workpieces or workpieces that can be easily rotated.

3. What are the factors to consider when selecting the appropriate rabbeting machine for a job?

- Size and shape of the workpiece.

- Depth, width, and angle of the rabbet.

- Material of the workpiece.

- Production volume.

4. What are the safety precautions to take when operating a rabbeting machine?

- Wear eye protection, hearing protection, and dust mask.

- Securely clamp the workpiece to the machine table.

- Keep hands clear of the cutting area.

- Use a push stick to feed the workpiece into the machine.

- Never reach over the moving cutter.

5. How do you maintain a rabbeting machine?

- Clean the machine regularly to remove dust and debris.

- Lubricate moving parts according to the manufacturer’s instructions.

- Inspect the cutter regularly for wear and tear.

- Calibrate the machine regularly to ensure accuracy.

6. What are the common problems that can occur when operating a rabbeting machine?

- Rabbet is not cut to the correct depth.

- Rabbet is not cut to the correct width.

- Rabbet is not cut at the correct angle.

- Workpiece is damaged during cutting.

- Machine is not operating properly.

7. How do you troubleshoot a rabbeting machine that is not operating properly?

- Check the power supply.

- Check the machine’s settings.

- Inspect the cutter for wear and tear.

- Check the workpiece for defects.

- Refer to the manufacturer’s manual for further troubleshooting steps.

8. What are the quality standards for rabbeting?

- Rabbet should be cut to the correct depth, width, and angle.

- Rabbet should be free of splinters and tear-out.

- Rabbet should be smooth and free of defects.

9. How do you ensure that the rabbets you cut meet the quality standards?

- Use a sharp cutter.

- Clamp the workpiece securely.

- Feed the workpiece into the machine slowly and evenly.

- Inspect the rabbet after each cut.

- Make adjustments to the machine settings as needed.

10. What is your experience with operating rabbeting machines?

- Number of years of experience.

- Types of rabbeting machines operated.

- Materials worked with.

- Quality of work produced.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rabbet Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rabbet Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rabbet Operator is an essential member of a manufacturing team, responsible for the precise shaping of wood or metal edges using a specialized machine called a rabbeting machine. This role demands technical proficiency, attention to detail, and a commitment to quality.

1. Rabbeting Wood and Metal Edges

The primary responsibility of a Rabbet Operator is to operate and maintain the rabbeting machine to create precise rabbets (rectangular grooves) on the edges of wood or metal components.

- Set up and adjust the rabbeting machine according to specifications, ensuring optimal cutting depth, width, and angle.

- Load and secure workpieces onto the machine, ensuring proper alignment and stability.

- Operate the machine safely and efficiently, monitoring cutting progress and making adjustments as needed.

- Inspect finished workpieces for accuracy, quality, and adherence to specifications.

2. Monitoring and Maintaining Equipment

To ensure the smooth and efficient functioning of the rabbeting machine, Rabbet Operators are responsible for its upkeep and maintenance.

- Regularly clean, lubricate, and adjust the machine to prevent breakdowns and ensure optimal performance.

- Monitor machine operation and identify any potential issues or malfunctions.

- Perform basic repairs and troubleshooting to resolve minor problems and minimize downtime.

- Report any major issues or maintenance requirements to supervisors promptly.

3. Material Handling and Inventory Management

Rabbet Operators ensure the efficient flow of materials and maintain inventory levels to support production.

- Unload and inspect incoming raw materials, verifying their quality and quantity.

- Maintain and organize inventory of workpieces, ensuring a steady supply for production.

- Communicate with colleagues and supervisors regarding material needs and inventory levels.

4. Quality Control and Continuous Improvement

A Rabbet Operator’s commitment to quality extends beyond the inspection of individual workpieces. They actively participate in quality control processes and contribute to continuous improvement initiatives.

- Identify and rectify defects in workpieces, adhering to established quality standards.

- Participate in quality control inspections and provide feedback to improve processes.

- Suggest and implement minor improvements to enhance efficiency, accuracy, and safety.

Interview Tips

To ace an interview for a Rabbet Operator position, candidates should showcase their technical skills, attention to detail, and eagerness to contribute to the team’s success. Here are some interview tips and preparation hacks:

1. Research the Company and Position

Thoroughly research the company’s industry, products, and culture to demonstrate your interest and understanding of the organization. Familiarity with the specific requirements of the Rabbet Operator role will help you tailor your answers to the interviewer’s questions.

2. Highlight Your Technical Expertise

Emphasize your knowledge of rabbeting machines, including their operation, setup, and maintenance. Quantify your experience and provide specific examples of your ability to produce high-quality rabbets on different materials.

3. Showcase Your Quality Orientation

Demonstrate your commitment to quality by describing your approach to defect detection and prevention. Share examples of how you have implemented quality control measures or suggested process improvements.

4. Emphasize Your Attention to Detail

Highlight your ability to work with precision and accuracy. Describe situations where you have successfully achieved tight tolerances and met demanding specifications.

5. Prepare for Common Questions

Anticipate common interview questions related to your experience, skills, and motivation. Practice your answers to questions such as “Tell me about a time when you had to troubleshoot a problem with a rabbeting machine” or “How do you handle working under pressure to meet deadlines?”

6. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer about the company, the team, and the position. This shows your engagement and interest in the opportunity.

7. Follow Up Professionally

After the interview, promptly send a thank-you note to the interviewer. Reiterate your interest in the position and express your appreciation for their time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rabbet Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.