Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rabble Furnace Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

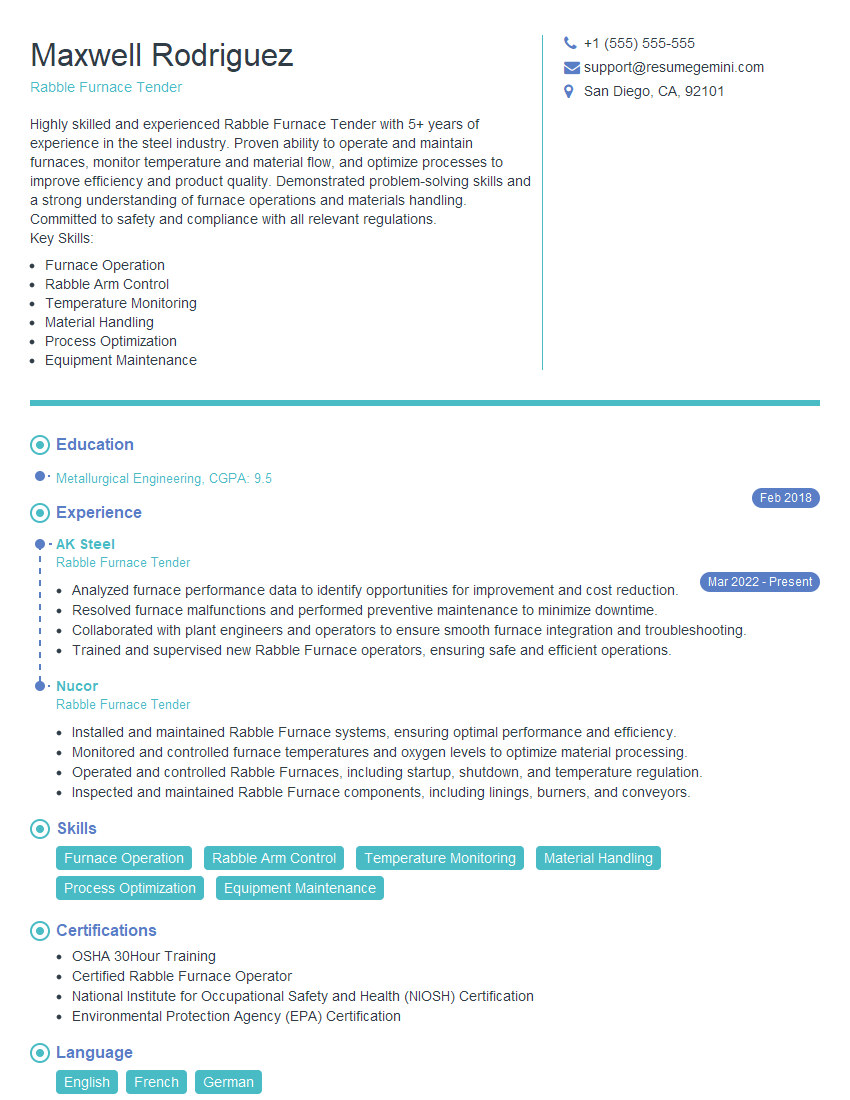

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rabble Furnace Tender

1. Describe the key responsibilities of a Rabble Furnace Tender?

As a Rabble Furnace Tender, my primary responsibilities would encompass:

- Operating and monitoring the furnace to ensure optimal performance and production.

- Adjusting furnace settings, such as temperature and fuel flow, to maintain desired operating parameters.

2. How do you ensure the safety of yourself and others while working with a Rabble Furnace?

Adherence to Safety Protocols

- Wearing appropriate personal protective equipment (PPE), including gloves, goggles, and heat-resistant clothing.

- Following established safety procedures and guidelines for operating the furnace.

Situational Awareness

- Maintaining constant vigilance for potential hazards, such as gas leaks or spills.

- Immediately reporting any safety concerns or incidents to supervisors or safety personnel.

3. What maintenance tasks are typically performed on a Rabble Furnace, and how often are they conducted?

Routine maintenance tasks for a Rabble Furnace include:

- Daily: Inspecting and cleaning the furnace, including the rabble arms and hearth.

- Weekly: Lubricating moving parts, such as bearings and gears.

- Monthly: Checking and adjusting the furnace’s burner and fuel system.

- Annually: Performing a comprehensive inspection and overhaul of the furnace, including replacing worn or damaged components.

4. How do you troubleshoot common issues that may arise during Rabble Furnace operation?

Common issues and troubleshooting steps include:

- Furnace overheating: Check fuel flow, burner settings, and air supply.

- Insufficient product agitation: Inspect rabble arms for damage or wear, and adjust agitation speed.

- Gas leaks: Use a gas detector to identify leaks and tighten loose fittings or replace damaged hoses.

5. What is the role of the rabble arms in a Rabble Furnace?

Rabble arms are essential for:

- Agitating the furnace charge to prevent caking and promote even heating.

- Moving the charge through the furnace to ensure complete processing.

6. How do you determine the appropriate furnace temperature for different materials being processed?

Determining the optimal furnace temperature involves:

- Consulting manufacturer’s specifications or material data sheets.

- Monitoring the furnace’s temperature readings and adjusting settings accordingly.

- Observing the material’s behavior and characteristics, such as melting point or sintering temperature.

7. What is the difference between a oxidizing and a reducing atmosphere in a Rabble Furnace?

- Oxidizing atmosphere: Contains excess oxygen, promoting oxidation reactions (e.g., rusting).

- Reducing atmosphere: Contains insufficient oxygen, preventing oxidation and promoting reduction reactions (e.g., forming carbon monoxide).

8. How do you calculate the fuel consumption of a Rabble Furnace?

Fuel consumption can be estimated using the following formula:

Fuel consumption = (Furnace output × Specific fuel consumption) / Caloric value of fuel

9. What are the key safety considerations when handling molten materials in a Rabble Furnace?

- Wearing appropriate heat-resistant PPE, including face shields and gloves.

- Using long-handled tools to keep a safe distance from molten materials.

- Being aware of potential splash zones and taking precautions to avoid contact.

10. How do you ensure the quality of the processed material in a Rabble Furnace?

- Monitoring the furnace temperature and atmosphere to maintain desired processing conditions.

- Performing regular inspections of the processed material to check for defects or inconsistencies.

- Adjusting furnace settings and operating parameters based on quality control feedback.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rabble Furnace Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rabble Furnace Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Rabble Furnace Tender

A Rabble Furnace Tender is responsible for operating and maintaining a furnace used to melt and refine copper or other non-ferrous metals.

1. Furnace Operation

The primary responsibility of a Rabble Furnace Tender is to ensure the proper functioning of the furnace. This includes:

- Monitoring and adjusting furnace temperatures and fuel flow

- Charging the furnace with raw materials and removing molten metal

- Maintaining proper oxygen levels and slag conditions

2. Equipment Maintenance

Rabble Furnace Tenders are also responsible for maintaining the furnace and associated equipment. This may include:

- Inspecting and repairing the furnace lining

- Maintaining and repairing mechanical and electrical components

- Ensuring compliance with safety regulations

3. Quality Control

Rabble Furnace Tenders play an important role in ensuring the quality of the molten metal produced. This includes:

- Sampling and analyzing molten metal

- Adjusting process parameters to meet quality specifications

- Documenting quality control records

4. Safety and Environmental Compliance

Rabble Furnace Tenders must prioritize safety and environmental compliance in all aspects of their work. This includes:

- Adhering to safety protocols

- Monitoring and controlling emissions

- Handling and disposing ofhazardous materials safely

Interview Preparation Tips for Rabble Furnace Tender Candidates

To ace an interview for a Rabble Furnace Tender position, candidates should:

1. Research the Company and Industry

Familiarize yourself with the company’s history, operations, and industry trends. This demonstrates your interest in the role and your understanding of the context in which you would be working.

2. Highlight Your Technical Skills

Emphasize your experience in operating and maintaining furnaces, as well as your knowledge of metallurgy and quality control procedures. Provide specific examples of your technical abilities.

3. Demonstrate Safety Consciousness

Safety is paramount in a Rabble Furnace Tender role. Highlight your commitment to safety and your understanding of industry best practices. Explain your experience in handling hazardous materials and adhering to safety regulations.

4. Prepare for Behavioral Interview Questions

Behavioral interview questions aim to assess your soft skills and problem-solving abilities. Practice answering questions about your experience working in a team, handling challenging situations, and making decisions under pressure.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. Prepare questions about the company’s growth plans, the specific responsibilities of the position, and opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rabble Furnace Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!