Feeling lost in a sea of interview questions? Landed that dream interview for Racquet Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Racquet Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

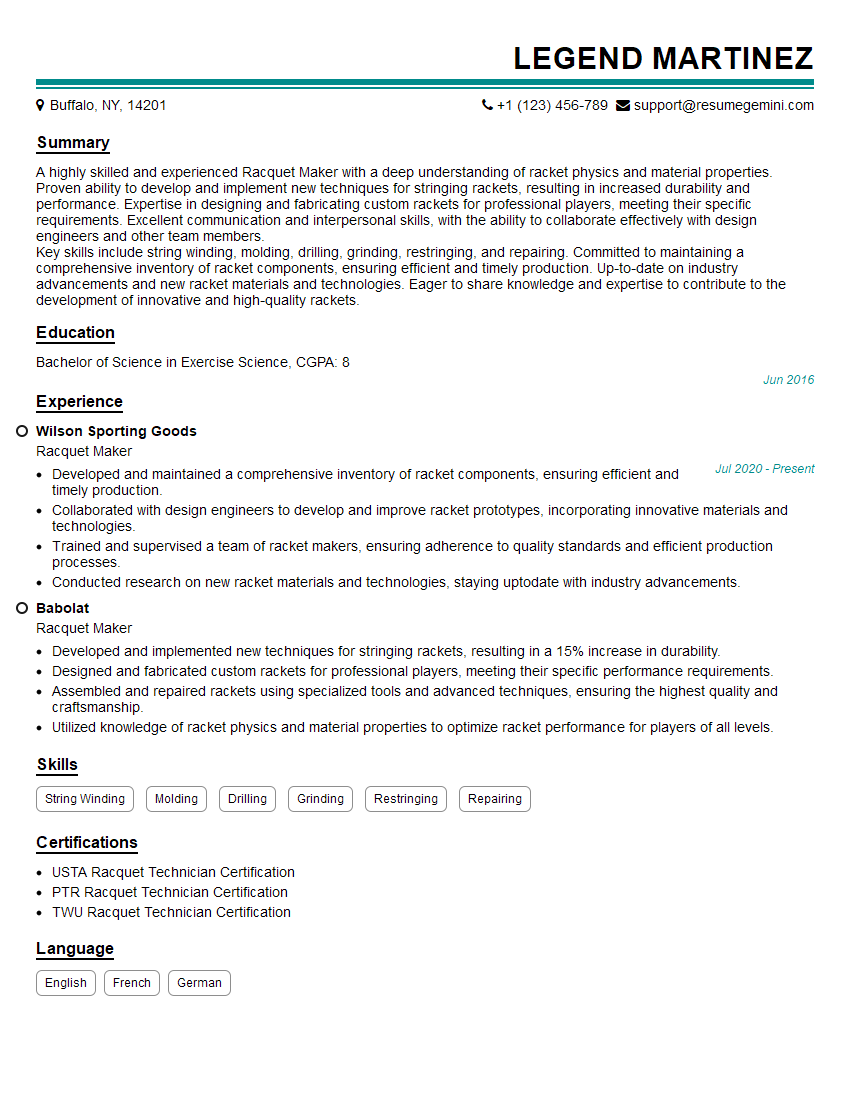

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Racquet Maker

1. What are the different types of materials used in racket making?

The different types of materials used in racket making include:

- Natural materials: Wood, bamboo, and animal gut

- Synthetic materials: Carbon fiber, Kevlar, and titanium

- Composite materials: Combinations of natural and synthetic materials

2. How do you select the appropriate materials for a specific racket?

Factors to Consider:

- Player’s playing style: Power, control, spin

- Racket weight and balance: Head-light, head-heavy, or even balance

- String tension and composition: Natural, synthetic, or hybrid

- Grip size and shape: Comfort and swing speed

Selection Process:

- Analyze the player’s needs

- Research and test different materials

- Create prototypes and test their performance

- Refine the design based on feedback and data analysis

3. What are the different steps involved in the racket manufacturing process?

The major steps involved in racket manufacturing are:

- Material selection and preparation

- Molding and shaping

- Stringing

- Finishing (e.g., painting, customization)

- Quality control and testing

4. How do you ensure the quality and consistency of your rackets?

To ensure quality and consistency, we implement the following measures:

- Strict material selection process

- Precise manufacturing techniques

- Rigorous quality control inspections

- Feedback collection from players and experts

- Continuous improvement through research and innovation

5. What are the current trends in racket technology?

Current trends in racket technology include:

- Increased use of composite materials for improved strength and durability

- Aerodynamic designs to reduce drag and improve swing speed

- Variable string patterns for enhanced spin and power

- Customizable rackets to meet the specific needs of individual players

- Integration of sensors and technology for data tracking and performance analysis

6. How do you stay up-to-date with the latest advancements in racket making?

To stay up-to-date, we engage in the following activities:

- Attend industry conferences and exhibitions

- Read technical publications and research papers

- Network with other racket makers and experts

- Participate in product development partnerships

- Conduct our own research and development initiatives

7. How do you handle customer inquiries and complaints about rackets?

We handle customer inquiries and complaints with the following approach:

- Respond promptly and courteously

- Listen attentively to the customer’s concerns

- Investigate the issue thoroughly

- Provide a resolution that meets the customer’s satisfaction

- Follow up to ensure the issue is resolved

8. What is your experience with using computer-aided design (CAD) software in racket making?

I am proficient in using CAD software such as [list of software]. I employ these tools for:

- Designing and modeling racket components

- Creating prototypes for testing

- Optimizing racket performance through simulations

- Generating technical drawings for production

- Collaborating with other engineers and designers

9. How do you control the production costs while maintaining the quality of rackets?

To control production costs without compromising quality, we implement the following strategies:

- Strategic procurement of materials

- Efficient production processes

- Lean manufacturing principles

- Waste reduction

- Investment in automation and technology

- Regular cost analysis and performance improvement initiatives

10. What are your career goals as a Racquet Maker?

My career goals as a Racquet Maker are:

- To continuously refine my skills and knowledge

- To contribute to the development of innovative and high-performance rackets

- To work with top athletes and coaches

- To become a recognized expert in the field

- To establish my own racket-making brand

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Racquet Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Racquet Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Racquet Makers play a significant role in the creation and maintenance of rackets used in various sports, primarily tennis and squash. Their responsibilities encompass a range of tasks related to the production, repair, and quality control of these rackets.

1. Production and Assembly

Racquet Makers are responsible for producing rackets from scratch or assembling them from pre-fabricated components. This involves cutting, shaping, and gluing wooden or composite materials to form the frame, attaching the strings, and ensuring the overall quality of the finished product.

- Select and prepare materials, including wood, graphite, or composite materials.

- Cut and shape the frame according to specifications.

- Glue and assemble the frame components.

- Attach the strings to the frame using specialized tensioning equipment.

2. Repairs and Maintenance

Racquet Makers also carry out repairs and maintenance on rackets to ensure they remain in optimal playing condition. This may involve fixing broken strings, replacing worn-out grips, or adjusting the tension of the strings.

- Identify and diagnose damage or issues with rackets.

- Repair broken strings or replace them with new ones.

- Replace worn-out or torn grips.

- Adjust the string tension and alignment to meet player specifications.

3. Quality Control

Racquet Makers are responsible for maintaining high standards of quality in the rackets they produce and repair. They conduct thorough inspections to ensure that the rackets meet the required specifications and are free from defects.

- Inspect raw materials and components for quality and durability.

- Test the finished rackets for strength, balance, and performance.

- Identify and correct any defects or imperfections.

- Maintain accurate records of repairs and maintenance performed.

4. Customer Service

Racquet Makers may also interact with customers to provide advice on racket selection, maintenance, and repairs. They may also take orders for custom-made rackets or offer recommendations based on the player’s needs and preferences.

- Provide information and advice to customers on racket selection and care.

- Take orders for custom-made or modified rackets.

- Follow up with customers to ensure satisfaction and address any concerns.

Interview Tips

Preparing for a job interview as a Racquet Maker requires a combination of technical knowledge, attention to detail, and effective communication skills. Here are some tips to help you ace your interview:

1. Research the Company and the Role

Before the interview, take the time to research the company you’re applying to and the specific role of Racquet Maker. Familiarize yourself with their products, services, and company culture. Understanding the company’s values and mission will help you tailor your answers to the interviewer’s questions and demonstrate your interest in the position.

- Visit the company’s website to learn about their history, products, and team.

- Read industry news and articles to stay updated on the latest trends and technologies.

- Check LinkedIn profiles of employees at the company to gain insights into the company culture and job requirements.

2. Highlight Your Skills and Experience

During the interview, emphasize your technical skills and experience as a Racquet Maker. Quantify your accomplishments and provide specific examples of projects you’ve worked on and the results you achieved. If you have experience in repairing or customizing rackets, be sure to highlight this.

- Prepare examples of rackets you’ve built or repaired, showcasing your craftsmanship and attention to detail.

- Quantify your results, such as the number of rackets you’ve produced or the customer satisfaction ratings you’ve received.

- Discuss any certifications or specialized training you have that demonstrates your expertise in racket making.

3. Demonstrate Your Passion and Attention to Detail

Racquet Makers are known for their passion for the sport and their meticulous attention to detail. Throughout the interview, convey your enthusiasm for racket making and your commitment to delivering high-quality products. Share examples of your personal projects or how you’ve gone above and beyond to meet customer expectations.

- Describe how you stay updated on the latest racket technologies and advancements.

- Discuss your interest in different types of rackets and their performance characteristics.

- Share stories of how you’ve solved complex problems or met challenging customer requests.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the role and the company. Prepare a list of questions related to the job, the company culture, or the industry. This demonstrates your enthusiasm and eagerness to learn more about the opportunity.

- Ask about the company’s commitment to quality and innovation.

- Inquire about opportunities for professional development and training.

- Ask about the company’s involvement in the community or industry events.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Racquet Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.