Are you gearing up for an interview for a Radial Drill Operator for Plastic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Radial Drill Operator for Plastic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

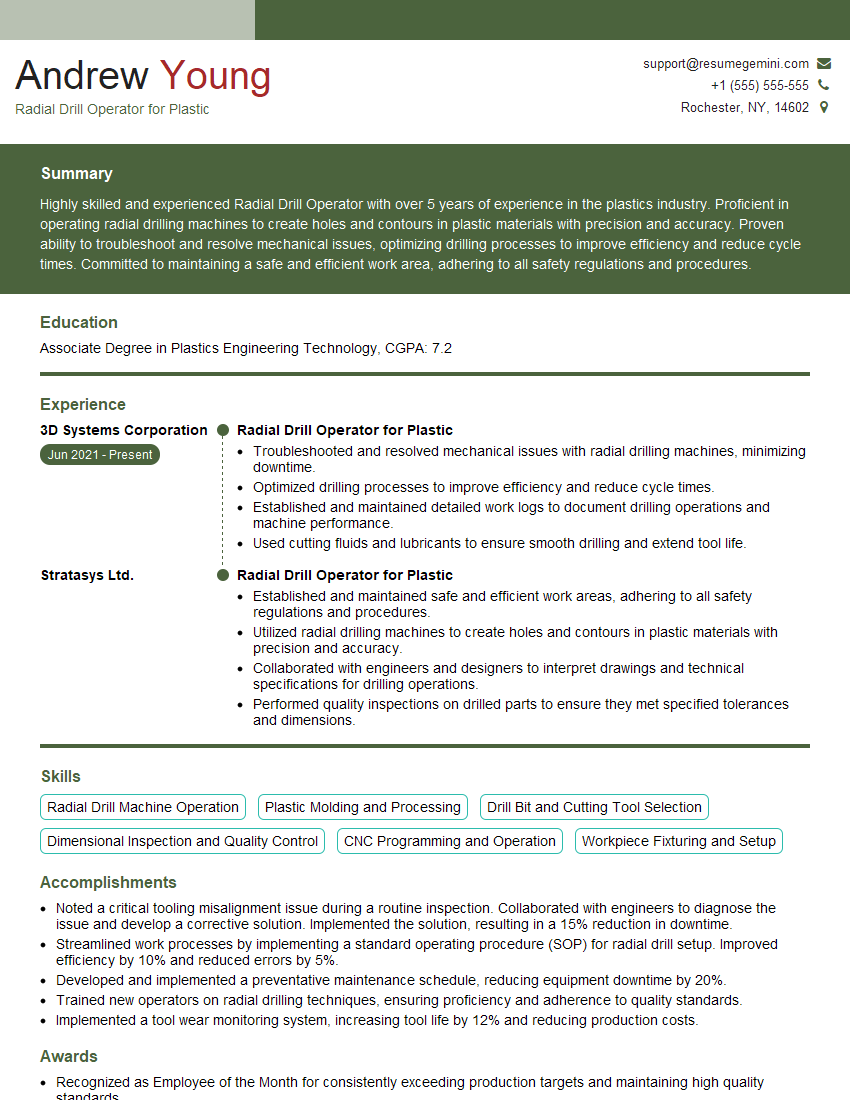

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Radial Drill Operator for Plastic

1. Can you describe the various types of radial drilling machines used for plastic drilling?

- Single-spindle radial drilling machines: These machines have a single spindle that can be moved radially around a central column.

- Multi-spindle radial drilling machines: These machines have multiple spindles that can be moved independently around a central column.

- CNC radial drilling machines: These machines are computer-controlled and can be programmed to perform complex drilling operations.

2. What are the key factors to consider when selecting tooling for radial drilling of plastics?

- The type of plastic being drilled

- The thickness of the plastic

- The desired hole size and shape

- The speed and feed rate of the drilling machine

3. How do you ensure the accuracy of holes drilled on a radial drilling machine?

- Properly set up the machine according to the manufacturer’s instructions

- Use sharp and properly sized drill bits

- Secure the workpiece properly

- Use a drill press vise or other fixturing to hold the workpiece securely

- Use a depth gauge to ensure that the holes are drilled to the correct depth

4. What are the safety precautions that must be observed when operating a radial drilling machine?

- Always wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Keep your hands away from the rotating drill bit.

- Never leave the machine unattended while it is running.

- Secure the workpiece properly before starting the machine.

- Use sharp drill bits and replace them when they become dull.

5. How do you troubleshoot common problems that may occur while operating a radial drilling machine?

- The drill bit is not cutting properly – check the sharpness of the drill bit, the speed and feed rate of the machine, and the type of plastic being drilled.

- The holes are not accurate – check the setup of the machine, the size of the drill bit, and the secureness of the workpiece.

- The machine is making excessive noise – check the bearings, gears, and other mechanical components of the machine for wear or damage.

6. What are the maintenance procedures that must be performed on a radial drilling machine?

- Regularly clean and lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine for wear or damage before each use.

- Replace worn or damaged parts promptly.

7. How do you calculate the speed and feed rate for drilling plastic on a radial drilling machine?

- Consult the manufacturer’s recommendations for the type of plastic being drilled.

- Use a speed and feed calculator to determine the appropriate settings for the machine.

- Experiment with different settings to find the optimal combination for the specific application.

8. What are the different types of coolants that can be used when drilling plastic on a radial drilling machine?

- Water-soluble coolants

- Oil-based coolants

- Synthetic coolants

9. How do you measure the diameter of a hole drilled on a radial drilling machine?

- Use a micrometer or calipers to measure the diameter of the hole.

- Compare the measurement to the specified hole diameter to ensure accuracy.

10. What are the advantages of using a radial drilling machine for drilling plastic?

- Radial drilling machines are versatile and can be used for a variety of drilling operations.

- Radial drilling machines are accurate and can produce high-quality holes.

- Radial drilling machines are relatively easy to operate and maintain.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Radial Drill Operator for Plastic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Radial Drill Operator for Plastic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Radial Drill Operator for Plastic plays a vital role in the production process, performing specialized tasks related to drilling and machining plastic materials. Key job responsibilities include:

1. Operation of Radial Drill Machine

Operate a radial drill machine efficiently to drill holes, bore, and counterbore plastic parts as per specified dimensions and tolerances.

- Set up and adjust the machine according to job requirements.

- Select and use appropriate drill bits and cutting tools.

2. Inspection and Quality Control

Inspect the drilled parts to ensure they meet specifications and quality standards.

- Use measuring tools and gauges to verify dimensions and tolerances.

- Identify and rectify any discrepancies or defects.

3. Maintenance and Housekeeping

Perform routine maintenance and cleaning of the radial drill machine and surrounding work area.

- Lubricate and clean the machine regularly.

- Maintain a clean and organized work environment.

4. Safety Compliance

Adhere to safety regulations and protocols while operating the radial drill machine and handling plastic materials.

- Wear appropriate personal protective equipment (PPE).

- Follow established safety procedures to prevent accidents and injuries.

Interview Tips

To ace an interview for a Radial Drill Operator for Plastic position, it is essential to prepare thoroughly and present yourself professionally. Here are some interview tips and preparation strategies:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and culture. Study the job description thoroughly to gain a clear understanding of the required skills and responsibilities.

2. Practice Answering Common Interview Questions

- Prepare for questions related to your experience in radial drill operation, quality control, and safety procedures.

- Consider using an Example Outline to structure your answers and provide specific examples of your work.

3. Highlight Your Skills and Experience

Emphasize your technical abilities in radial drill operation, measurement, and inspection. Showcase your attention to detail and commitment to quality.

4. Demonstrate Your Safety Knowledge

Stress your understanding of safety regulations and your adherence to safety protocols. Explain how you prioritize safety in your work environment.

5. Be Punctual and Professional

Arrive on time for your interview and dress professionally. Maintain a positive and respectful demeanor throughout the interview process.

Next Step:

Now that you’re armed with the knowledge of Radial Drill Operator for Plastic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Radial Drill Operator for Plastic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini