Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Radial Drill Press Operator for Plastic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

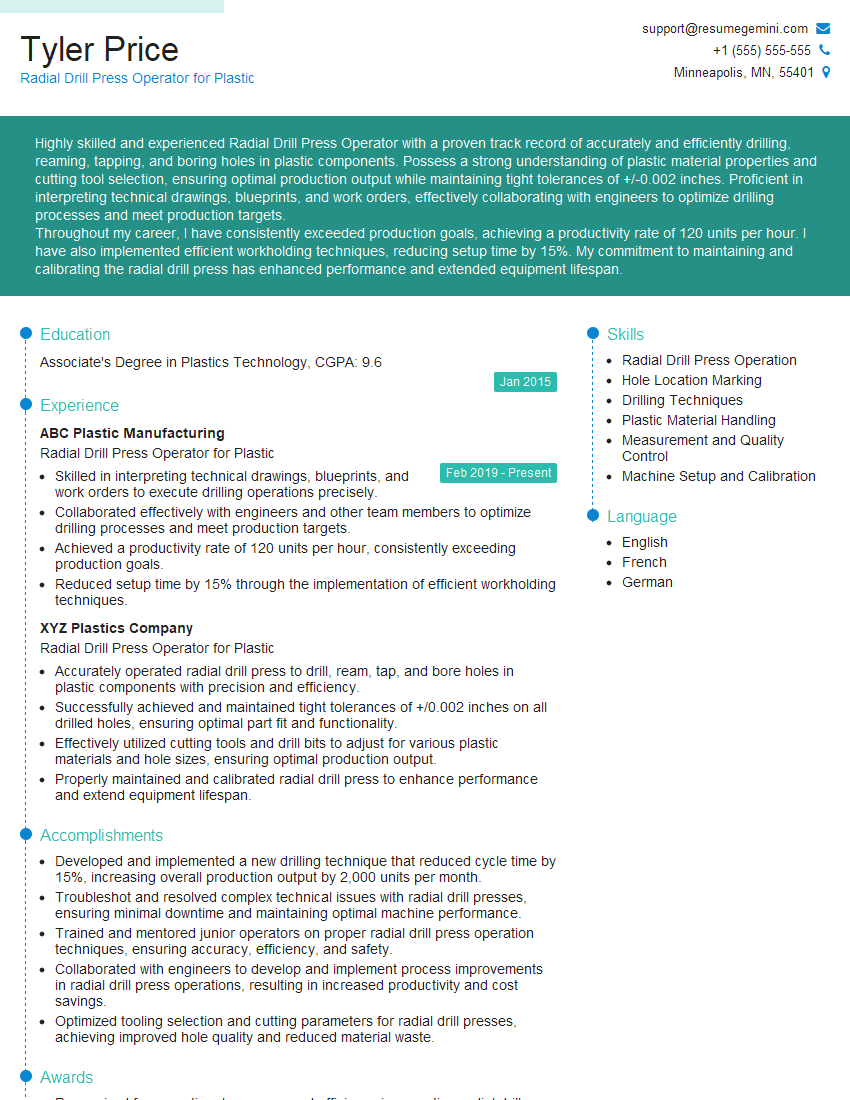

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Radial Drill Press Operator for Plastic

1. Describe the process of setting up and operating a radial drill press for plastic drilling operations.

Answer:

- Inspect the plastic workpiece to ensure it is free from defects or damage.

- Select the appropriate drill bit size and type based on the required hole diameter and material thickness.

- Mount the drill bit in the drill chuck and tighten it securely using a drill chuck key.

- Position the workpiece on the drill press table and secure it using clamps or a vise.

- Adjust the drill press settings, including speed, feed rate, and depth of cut.

- Start the drill press and carefully guide the drill bit into the workpiece.

- Monitor the drilling process and adjust settings as necessary to maintain optimal performance.

- Once the hole is complete, retract the drill bit and stop the drill press.

2. How do you determine the correct drill bit speed and feed rate for drilling plastic?

Drill Bit Speed

- Higher speeds for smaller drill bits.

- Lower speeds for larger drill bits.

- Refer to drill bit manufacturer’s recommendations.

Feed Rate

- Slower feed rates for softer plastics.

- Faster feed rates for harder plastics.

- Experiment to determine optimal feed rate based on material and desired finish.

3. What are the common causes of drill bit breakage when drilling plastic?

Answer:

- Using a dull or chipped drill bit.

- Incorrect drill bit speed or feed rate.

- Excessive pressure applied while drilling.

- Improperly secured workpiece.

- Poor drill press maintenance.

4. How do you ensure the accuracy of drilled holes in plastic?

Answer:

- Use a sharp, high-quality drill bit.

- Clamp or secure the workpiece securely.

- Double-check measurements and settings before drilling.

- Use a drill press guide or template for greater precision.

- Drill pilot holes for larger holes to improve accuracy.

5. What are the different types of plastic drilling operations?

Answer:

- Through-hole drilling: Creating holes that pass completely through the workpiece.

- Blind-hole drilling: Creating holes that do not penetrate the entire thickness of the workpiece.

- Counterboring: Creating a wider recess around a hole to accommodate a fastener head.

- Countersinking: Creating a tapered recess around a hole to accommodate a screw head flush with the surface.

6. What safety precautions should be taken when operating a radial drill press?

Answer:

- Wear appropriate safety gear, including eye protection, gloves, and hearing protection.

- Keep work area clean and free of debris.

- Secure the workpiece properly before drilling.

- Avoid loose clothing or jewelry that can get caught in the drill.

- Be aware of the drill bit’s position and movement at all times.

7. How do you troubleshoot common problems associated with radial drill press operations?

Answer:

- Drill bit breakage: Check for dull or chipped bits, incorrect speed/feed rates, or excessive pressure.

- Poor hole quality: Use sharper bits, adjust feed rate, or secure the workpiece better.

- Machine vibration: Inspect bearings and belts for wear, balance the drill bit.

- Difficulty feeding the drill bit: Check for obstruction in the workpiece, adjust feed rate, or lubricate the drill bit.

8. What maintenance tasks are required for a radial drill press?

Answer:

- Clean and lubricate the machine regularly.

- Inspect and replace worn or damaged parts, such as belts, bearings, and drill chucks.

- Calibrate the machine periodically to ensure accuracy.

- Follow manufacturer’s recommendations for maintenance and servicing.

9. How do you optimize the efficiency of radial drill press operations?

Answer:

- Use sharp, high-performance drill bits.

- Experiment with different speed/feed rate combinations to find the optimal settings.

- Secure the workpiece properly to minimize vibration and improve accuracy.

- Utilize drill press accessories such as drill vises and guides to enhance productivity.

10. Describe your experience in working with radial drill presses for plastic drilling operations.

Answer:

- Highlight your experience in operating radial drill presses specifically for plastic materials.

- Quantify your achievements and results, such as increased productivity or improved hole quality.

- Emphasize your knowledge of plastic drilling techniques and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Radial Drill Press Operator for Plastic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Radial Drill Press Operator for Plastic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Radial Drill Press Operators for Plastic play a crucial role in manufacturing processes involving plastic components. Their primary responsibilities include:1. Machine Operation

Operate radial drill presses to drill holes in plastic parts according to specified dimensions and tolerances.

- Set up and configure machines with appropriate tooling and fixtures.

- Securely hold and align workpieces for drilling operations.

- Adjust drill speeds, feed rates, and depths to achieve optimal results.

2. Quality Control

Ensure the quality and accuracy of drilled parts.

- Inspect finished parts using measuring instruments to verify dimensions and hole locations.

- Identify and rectify any deviations from specifications or quality standards.

- Maintain records of inspections and quality control measures.

3. Maintenance

Perform routine maintenance and cleaning of drill presses and associated equipment.

- Lubricate moving parts, adjust belts, and replace worn components.

- Clean and remove chips and debris from machines and work areas.

- Monitor equipment performance and report any potential issues or malfunctions.

4. Production Efficiency

Maximize production efficiency by optimizing machine settings and processes.

- Identify and implement ways to reduce setup times and minimize downtime.

- Use jigs and fixtures to improve part accuracy and consistency.

- Work in collaboration with other team members to streamline production operations.

Interview preparation Tips

To ace your interview for the position of Radial Drill Press Operator for Plastic, consider these tips:1. Research the company and industry

Demonstrate your understanding of the plastic manufacturing industry and the company’s products and services. Research their website, news articles, and social media to gain insights into their business operations.

- Highlight any relevant experience or knowledge you have in the plastics industry.

- Show that you are familiar with the specific types of plastics used in their manufacturing processes.

2. Emphasize your technical skills

Clearly articulate your proficiency in radial drill press operation. Provide specific examples of your experience in setting up, operating, and maintaining these machines.

- Quantify your accomplishments by providing specific metrics or results.

- Mention any certifications or specialized training you have received in radial drill press operation.

3. Showcase your quality control expertise

Highlight your attention to detail and commitment to quality. Explain your understanding and experience in inspecting plastic parts, identifying defects, and ensuring product quality.

- Describe the quality control procedures you have implemented in previous roles.

- Emphasize your ability to interpret blueprints and technical specifications.

4. Highlight your teamwork and communication skills

Radial Drill Press Operators often work in production teams. Showcase your ability to collaborate with others, communicate effectively, and contribute to a positive work environment.

- Provide examples of how you have worked effectively with colleagues to improve production processes.

- Demonstrate your willingness to share knowledge and assist other team members.

5. Prepare questions to ask the interviewer

Asking thoughtful questions during the interview shows your engagement and interest in the role. Prepare questions that demonstrate your industry knowledge, enthusiasm for the position, and understanding of the company’s operations.

- Inquire about the company’s quality control standards and their approach to continuous improvement.

- Ask about opportunities for training and professional development within the organization.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Radial Drill Press Operator for Plastic role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.