Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Radial Drill Press Set-Up Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

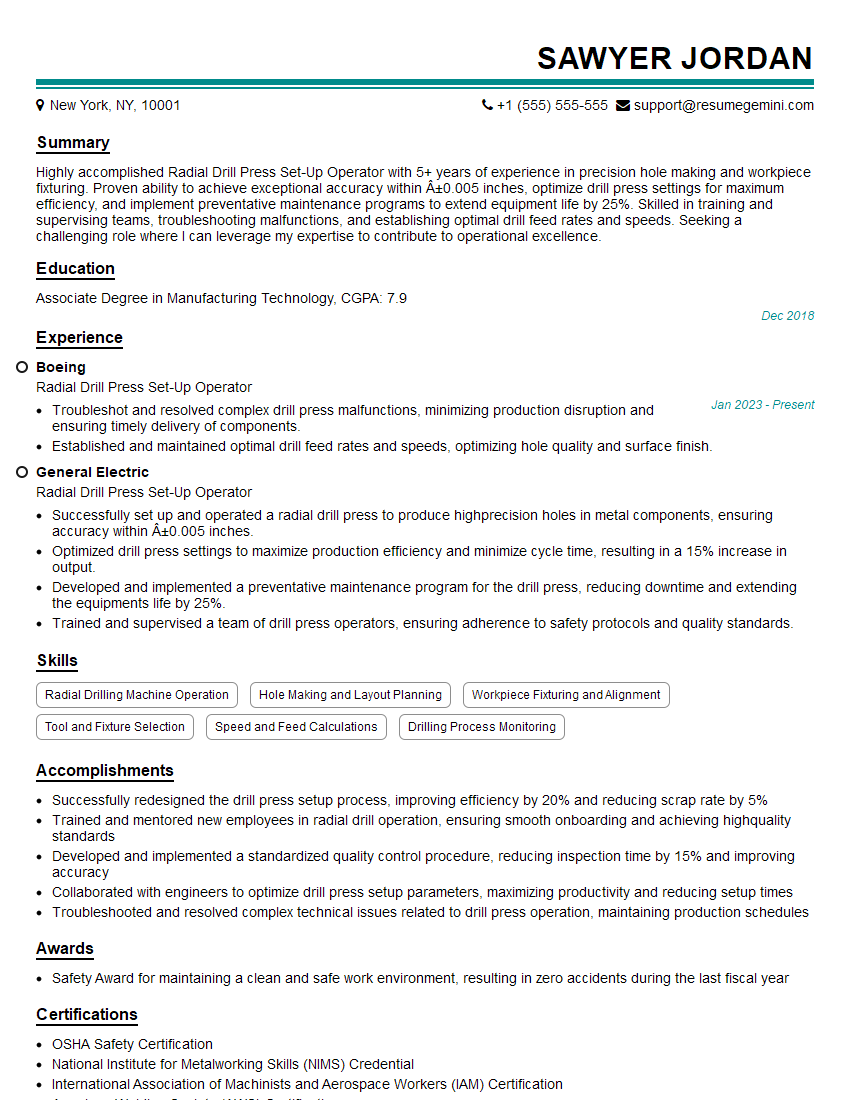

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Radial Drill Press Set-Up Operator

1. What are the key steps involved in setting up a radial drill press?

• Ensure the machine is level and secure by checking the oil level, tightening any loose bolts, and cleaning the work surface.

• Select the appropriate spindle and drilling bit for the job.

• Set the spindle speed and feed rate according to the material being drilled.

• Align the workpiece on the table using the table clamps.

• Adjust the head height and arm position to achieve the desired hole location and depth.

2. How do you determine the correct spindle speed and feed rate for a given drilling operation?

Factors to consider:

- Material hardness and thickness

- Drill bit size and type

- Desired surface finish

General guidelines:

- Harder materials require lower spindle speeds and higher feed rates.

- Larger drill bits require higher spindle speeds and lower feed rates.

- A finer surface finish requires higher spindle speeds and lower feed rates.

3. What are some common troubleshooting steps for a radial drill press that is not operating correctly?

• Check for loose connections, damaged wires, or blown fuses.

• Inspect the spindle for wear or damage and replace if necessary.

• Clean the chuck and ensure the drill bit is securely tightened.

• Verify that the workpiece is properly clamped and not moving during operation.

• Check the coolant system for leaks or blockages.

4. What are the safety precautions that need to be followed when operating a radial drill press?

- Wear appropriate safety gear such as eye protection, earplugs, and gloves.

- Secure loose clothing and remove jewelry to prevent entanglements.

- Keep the work area clean and free of debris

- Do not operate the drill press under the influence of drugs or alcohol.

- Never leave the drill press running unattended.

5. What are some tips for optimizing the efficiency and accuracy of a radial drill press?

- Use sharp drill bits and replace them regularly.

- Ensure the spindle is running true by checking for runout.

- Lubricate the machine regularly to reduce friction and wear.

- Use coolant to extend drill bit life and improve surface finish.

- Secure the workpiece securely to prevent movement during drilling.

6. What are the different types of drilling operations that can be performed on a radial drill press?

- Center drilling

- Spot drilling

- Drilling through holes

- Reaming

- Tapping

7. How do you ensure that the holes drilled on a radial drill press are perpendicular to the workpiece surface?

- Use a square or height gauge to align the workpiece perpendicular to the drill bit.

- Adjust the drill press head to ensure the spindle is perpendicular to the workpiece.

- Drill a pilot hole first to guide the drill bit and prevent it from wandering.

8. What is the difference between a radial drill press and a vertical drill press?

- Radial drill press: Arm moves horizontally and vertically, allowing for greater flexibility and reach.

- Vertical drill press: Spindle moves vertically only, suitable for smaller workpieces and precise drilling.

9. What are the advantages of using a radial drill press over other drilling machines?

- Large capacity and flexibility for drilling holes in large workpieces.

- Adjustable head and arm for versatile drilling angles and positions.

- Heavy-duty construction and powerful motor for efficient drilling.

10. What are some of the latest advancements in radial drill press technology?

- CNC control for increased precision and automation.

- Automatic tool changers for faster and more efficient operation.

- Laser alignment systems for accurate hole placement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Radial Drill Press Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Radial Drill Press Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Radial Drill Press Set-Up Operator is responsible for setting up and operating a radial drill press to drill holes in metal and other materials. Key job responsibilities include:

1. Set up and operate radial drill press

This involves mounting the drill bit, adjusting the spindle speed and feed rate, and positioning the workpiece.

2. Inspect and measure workpieces

This is to ensure that they meet specifications and are free of defects.

3. Maintain drill press and tooling

To keep it in good working condition and prevent breakdowns.

4. Follow safety procedures

To ensure a safe work environment and prevent accidents.

Interview Tips

To ace an interview for a Radial Drill Press Set-Up Operator position, it is important to be prepared. Here are some tips:

1. Research the company and the position

This will help you understand the company’s culture and the specific requirements of the job.

2. Practice answering common interview questions

This will help you feel more confident and prepared during the interview. Common questions include:

- Tell me about your experience operating a radial drill press.

- How do you ensure that workpieces meet specifications?

- What is your safety record?

3. Be prepared to discuss your skills and experience

Highlight your skills and experience that are relevant to the job, such as your ability to set up and operate a radial drill press, your attention to detail, and your safety consciousness.

4. Be enthusiastic and positive

Let the interviewer know that you are excited about the opportunity to work for the company and that you are confident in your abilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Radial Drill Press Set-Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!