Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Radio Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

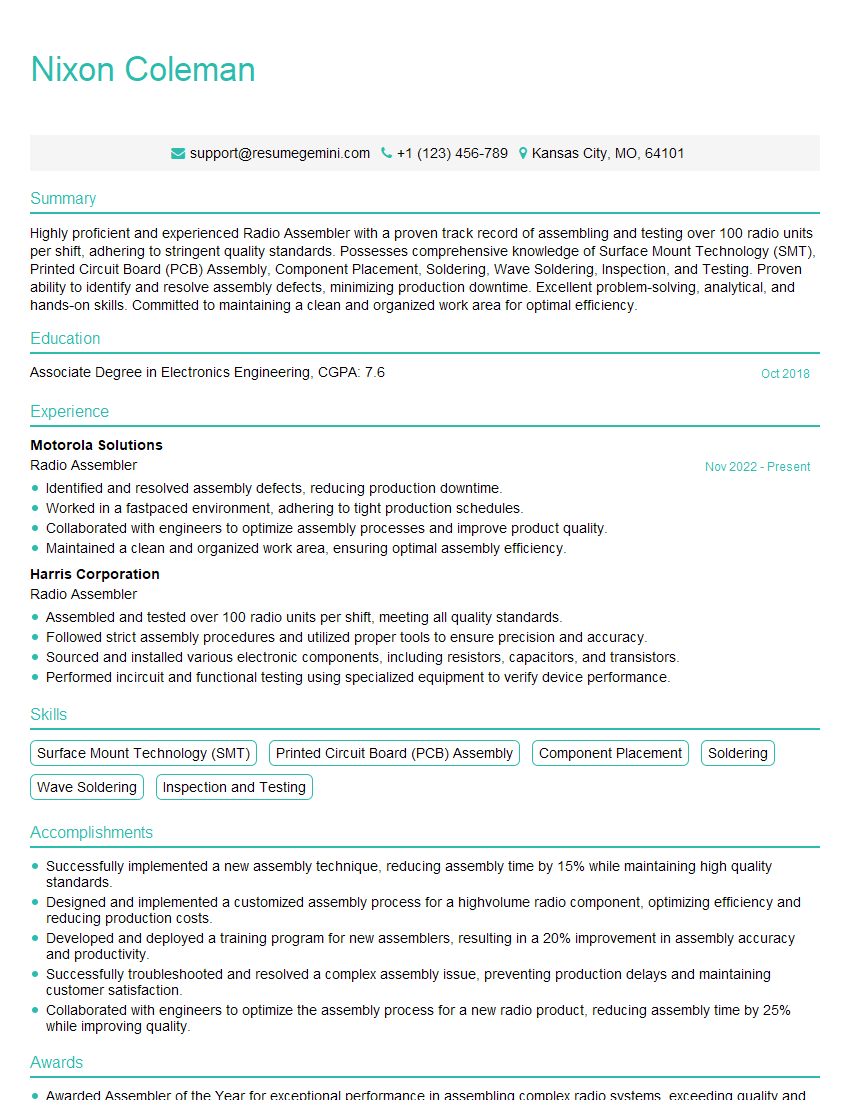

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Radio Assembler

1. What are the different types of radio assemblies?

Here are the different types of radio assemblies:

- Tuner Assembly: Responsible for receiving radio signals and converting them into an audio signal.

- Amplifier Assembly: Amplifies the audio signal to a level suitable for driving the speaker.

- Speaker Assembly: Converts the amplified audio signal into sound waves.

- Control Panel Assembly: Allows the user to control the radio’s functions, such as volume, tuning, and power.

- Power Supply Assembly: Provides power to the other components of the radio.

2. What are the key steps involved in assembling a radio?

Key steps in radio assembly include:

- Component Inspection: Verify the quality and condition of all components.

- Soldering: Connect electronic components to the printed circuit board (PCB) using solder.

- Wiring: Connect the various assemblies and components using wires or cables.

- Testing: Perform electrical tests to ensure the radio meets specifications.

- Quality Control: Inspect the assembled radio for defects or errors.

3. What are the common troubleshooting techniques used for radio assemblies?

Common troubleshooting techniques for radio assemblies:

- Visual Inspection: Examine the assembly for any obvious defects or damage.

- Ohmmeter Testing: Measure the resistance of components and circuits to identify potential shorts or open connections.

- Signal Tracing: Use an oscilloscope or signal generator to track the signal path through the assembly.

- Component Swapping: Replace suspected faulty components with known-good ones to isolate the problem.

- Schematic Analysis: Refer to the schematic diagram to analyze the circuit and identify potential issues.

4. What are the safety precautions that should be observed when assembling and troubleshooting radios?

Safety precautions for radio assemblers and troubleshooters include:

- Use appropriate tools: Ensure that all tools are in good condition and used correctly.

- Wear protective gear: Wear safety glasses, gloves, and an anti-static wrist strap to protect against electrical hazards.

- Handle components with care: Avoid touching sensitive electronic components directly with bare hands.

- Be aware of electrical hazards: Understand the risks associated with electricity and take appropriate precautions.

- Work in a well-ventilated area: Fumes from soldering or other materials can be harmful.

5. What are the different types of soldering techniques used in radio assembly?

Common soldering techniques in radio assembly:

- Hand Soldering: Using a soldering iron to manually solder components to the PCB.

- Wave Soldering: Passing the PCB over a molten solder wave to solder multiple components simultaneously.

- Reflow Soldering: Applying heat to solder paste on the PCB to reflow and create solder joints.

- Surface Mount Technology (SMT): Soldering components directly onto the surface of the PCB.

- Through-Hole Technology (THT): Inserting component leads through holes in the PCB and soldering them on the other side.

6. What are the quality control standards and procedures followed in radio assembly?

Quality control standards in radio assembly include:

- Incoming Inspection: Verifying the quality of incoming components and materials.

- In-Process Inspection: Monitoring the assembly process at various stages to ensure compliance with specifications.

- Final Inspection: Thorough testing and inspection of the assembled radio before packaging.

- Statistical Process Control (SPC): Using statistical methods to monitor and improve assembly processes.

- Documentation: Maintaining detailed records of all inspections and tests performed.

7. What are the common causes of defects in radio assemblies?

Common causes of defects in radio assemblies include:

- Soldering defects: Cold joints, solder bridges, or improper flux application.

- Component failure: Faulty or damaged components due to incorrect handling or manufacturing errors.

- PCB defects: Etching errors, solder mask issues, or damaged traces.

- Assembly errors: Incorrect component placement, missing components, or reversed polarity.

- Environmental factors: Exposure to moisture, dust, or extreme temperatures.

8. What are the latest trends and advancements in radio assembly technology?

Recent advancements in radio assembly technology include:

- Surface Mount Technology (SMT): Increased use of SMT for miniaturization and cost reduction.

- Automated Optical Inspection (AOI): Automated inspection systems using cameras to detect assembly defects.

- Lead-free Soldering: Transition to lead-free solder to meet environmental regulations.

- Digital Radio: Assembly of digital radio devices using software-defined radio (SDR) technology.

- Internet of Things (IoT): Integration of radios into IoT devices for remote monitoring and control.

9. How do you stay updated with the latest industry standards and best practices in radio assembly?

To stay updated, I:

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Participate in online forums and discussion groups.

- Seek training and certification from recognized organizations.

- Network with other professionals in the field.

10. Describe a time when you successfully resolved a complex issue in radio assembly.

In a previous project, we encountered a persistent issue with a radio assembly that failed to pass quality control. After thorough troubleshooting using oscilloscopes and signal tracing, we identified a subtle defect in the amplifier circuit. The issue was caused by an incorrect resistor value that was not detected during initial inspection. By replacing the faulty resistor with the correct value, we successfully resolved the issue and the radio passed all subsequent tests.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Radio Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Radio Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Radio Assemblers play a crucial role in the production of radios and other communication devices. They are responsible for assembling and testing various components to ensure that the final product meets the required specifications.

1. Component Assembly

Radio Assemblers are responsible for assembling various components of radios, such as circuit boards, transistors, resistors, and capacitors. They follow assembly instructions and diagrams to ensure that all components are correctly positioned and connected.

- Soldering and connecting electrical components.

- Installing electronic components onto circuit boards.

- Assembling radio chassis and enclosures.

2. Testing and Inspection

Radio Assemblers test assembled radios to ensure that they meet performance specifications. They use various testing equipment to evaluate parameters such as signal strength, frequency response, and power output.

- Conducting functional tests on assembled radios.

- Identifying and troubleshooting any defects or malfunctions.

- Ensuring compliance with quality standards.

3. Quality Assurance

Radio Assemblers are responsible for maintaining quality standards throughout the assembly process. They inspect incoming materials and components to ensure they meet specifications.

- Monitoring production processes to ensure accuracy and efficiency.

- Inspecting finished products for any defects or errors.

- Implementing quality control procedures.

4. Maintenance and Repair

Radio Assemblers may also be involved in maintaining and repairing radios and other communication devices. They troubleshoot problems, replace defective components, and perform necessary repairs.

- Maintaining and repairing radios and other communication equipment.

- Troubleshooting electrical and mechanical issues.

- Replacing defective components and performing necessary repairs.

Interview Tips

Preparing for a Radio Assembler interview can help you highlight your skills and experience and increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and Position

Research the company’s website and industry publications to understand their business, products, and culture. Review the job description carefully to identify the key responsibilities and qualifications required for the position.

- Visit the company’s website to learn about their history, values, and products.

- Read industry news and articles to stay informed about the latest trends and technologies.

- Carefully review the job description and highlight your skills and experience that match the requirements.

2. Practice Your Answers

Prepare for common interview questions related to your skills, experience, and knowledge of the industry. Practice answering questions out loud to improve your confidence and delivery.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your accomplishments.

- Practice answering questions in front of a mirror or with a friend or family member.

- Time yourself to ensure you can provide concise and informative answers within the allotted time.

3. Highlight Your Skills and Experience

During the interview, emphasize your skills and experience that are relevant to the job requirements. Provide specific examples of projects or tasks you have completed that demonstrate your abilities.

- Showcase your technical skills, such as soldering, component assembly, and testing.

- Highlight your attention to detail and ability to work in a fast-paced environment.

- Demonstrate your understanding of radio principles and communication systems.

4. Be Enthusiastic and Professional

Show your enthusiasm for the position and the opportunity to work for the company. Maintain a positive and professional attitude throughout the interview.

- Dress appropriately for the interview and arrive on time.

- Be respectful and listen attentively to the interviewer’s questions.

- Ask thoughtful questions at the end of the interview to show your interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Radio Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!