Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Radio Machinist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

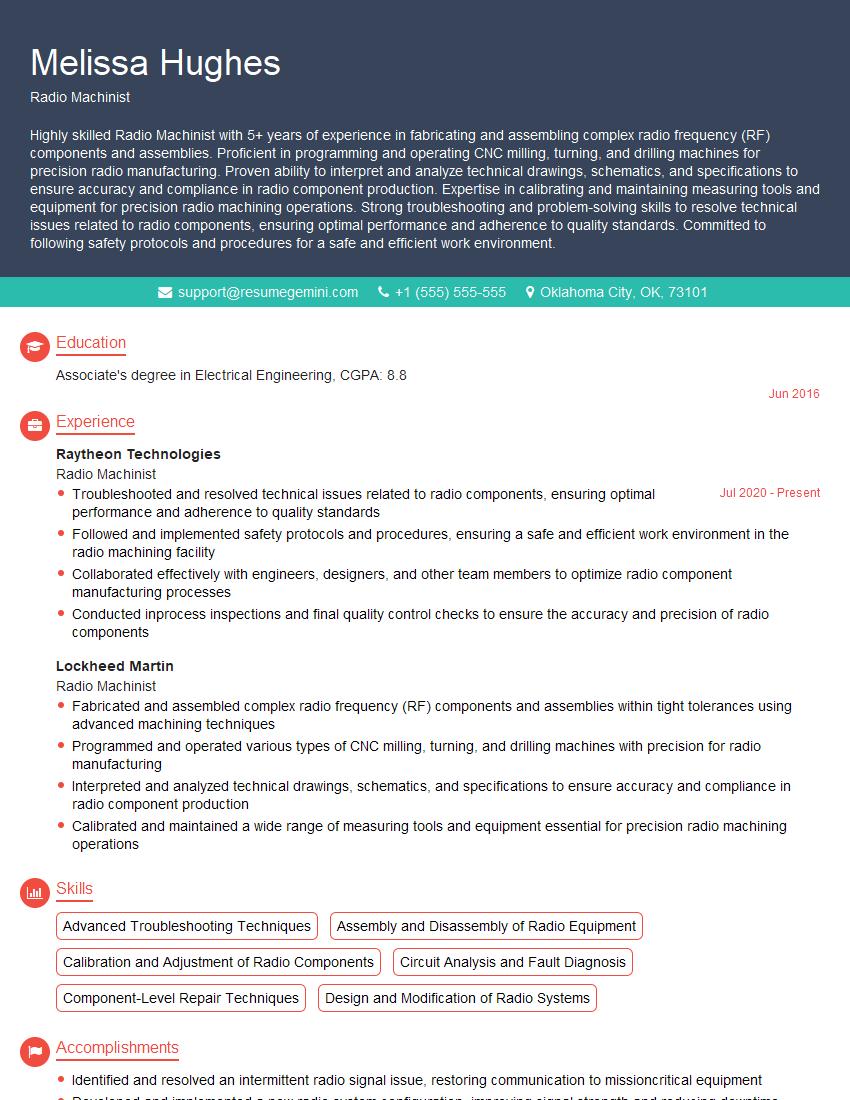

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Radio Machinist

1. Explain the process of machining a radio chassis?

The process of machining a radio chassis involves several steps and can vary depending on the specific design and materials used. Here is a general overview of the process:

- Design and planning: The first step involves designing the chassis based on the radio’s specifications and requirements. This includes determining the dimensions, shape, and material.

- Material selection: The choice of material for the chassis is critical. Common materials used include aluminum, steel, and brass.

- Cutting and shaping: The material is cut and shaped according to the design using various machining techniques such as milling, drilling, and punching.

- Forming and bending: The chassis may require forming or bending to create specific shapes and angles.

- Drilling and tapping: Holes are drilled and tapped to accommodate components, such as mounting bolts, connectors, and switches.

- Finishing: The chassis is finished to protect it from corrosion and enhance its appearance. This may involve processes such as anodizing, painting, or powder coating.

- Assembly: Once the chassis is complete, it is assembled with other components of the radio, such as the circuit board, display, and controls.

2. What are the different types of materials used in radio chassis and their properties?

Aluminum

- Lightweight and strong

- Excellent machinability

- Corrosion-resistant

- Good thermal conductivity

Steel

- Strong and durable

- Can be treated for improved corrosion resistance

- Heavier than aluminum

- Less machinable than aluminum

Brass

- Corrosion-resistant

- Good electrical conductivity

- Machinable but more challenging than aluminum

- Relatively soft

3. Describe the different types of machining operations used in radio chassis fabrication?

- Milling: Used to create flat or contoured surfaces, slots, and pockets.

- Drilling: Used to create holes for mounting, component placement, and wire routing.

- Punching: Used to create precise holes or cutouts in sheet metal.

- Forming: Used to bend or shape the chassis into specific shapes, such as curves or angles.

- Tapping: Used to create threads in holes for mounting screws or other fasteners.

4. What are the important tolerances to consider when machining a radio chassis and how are they achieved?

- Dimensional tolerances: These ensure that the chassis fits properly with other components and meets functional requirements.

- Geometric tolerances: These control the shape, orientation, and surface finish of the chassis.

- **Tolerances are achieved through precise machining techniques, proper tooling, and quality control measures.

5. Describe the importance of surface finish in radio chassis fabrication?

- Smooth surface finish: Provides better contact between components and improves overall performance.

- Reduces friction: A smooth surface finish reduces friction between moving parts, improving efficiency and wear resistance.

- Enhances aesthetics: A well-finished chassis enhances the overall appearance of the radio.

- Facilitates cleaning: A smooth surface is easier to clean, preventing dirt and debris buildup.

6. What are the common challenges faced in radio chassis fabrication and how are they overcome?

- Maintaining tolerances: Precision machining techniques and proper tooling are used to achieve tight tolerances.

- Material selection: Choosing the right material for the application ensures durability and performance.

- Complex shapes: Advanced machining techniques, such as CNC (Computer Numerical Control) machining, allow for the fabrication of complex shapes.

- Surface finish: Proper machining practices and finishing techniques ensure a high-quality surface finish.

7. How do you stay updated with the latest advancements in radio chassis design and fabrication techniques?

- Industry events and conferences: Attending industry events and conferences allows for networking with experts and learning about the latest trends.

- Technical journals and publications: Reading technical journals and publications keeps you informed about new materials, technologies, and best practices.

- Online resources and forums: Participating in online forums and accessing technical resources provides valuable information.

- Training and professional development: Continuous training and professional development helps you stay abreast of industry advancements.

8. What are the current industry trends in radio chassis design?

- Miniaturization: Smaller and more compact chassis designs to meet the demands of portable and embedded devices.

- Multi-functionality: Chassis designs that integrate multiple functions, such as heat dissipation and shielding.

- Lightweight materials: The use of lightweight materials, such as aluminum alloys and composites, for improved portability.

- Advanced surface treatments: Coatings and treatments to enhance durability, corrosion resistance, and electromagnetic interference (EMI) shielding.

9. How do you handle complex design requirements in radio chassis fabrication?

- Collaboration with design engineers: Working closely with design engineers to understand the functional and performance requirements.

- Prototyping: Creating prototypes to test and refine the design before mass production.

- Advanced machining techniques: Utilizing advanced machining techniques, such as CNC machining, to achieve complex shapes and features.

- Material selection: Selecting the appropriate material and manufacturing processes to meet the performance and durability requirements.

10. Describe your experience in working with different types of radio communication systems?

- Two-way radios: Worked on the fabrication of chassis for handheld and mobile two-way radios.

- Satellite communication systems: Assisted in the development of chassis for satellite terminals and antennas.

- Cellular base stations: Contributed to the design and fabrication of chassis for cellular base stations and equipment.

- Broadcast systems: Involved in the fabrication of chassis for broadcast transmitters and receivers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Radio Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Radio Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Radio Machinists are responsible for a wide range of tasks related to the design, development, and repair of radio equipment. They work with a variety of materials and tools to create and maintain equipment that is used for communication, navigation, and other purposes. Some of the key responsibilities of a Radio Machinist include:

1. Design and development of radio equipment

Radio Machinists work closely with engineers to design and develop new radio equipment. They use their knowledge of radio technology to create prototypes and test equipment to ensure that it meets specifications.

2. Fabrication of radio components

Radio Machinists use a variety of tools and techniques to fabricate radio components. They work with materials such as metal, plastic, and ceramics to create parts that are used in the assembly of radio equipment.

3. Assembly of radio equipment

Radio Machinists assemble radio equipment according to specifications. They work with a variety of tools and techniques to ensure that equipment is assembled correctly and meets quality standards.

4. Repair and maintenance of radio equipment

Radio Machinists repair and maintain radio equipment. They use their knowledge of radio technology to diagnose problems and make repairs. They also perform preventive maintenance to keep equipment in good working order.

Interview Tips

Preparing for an interview for a Radio Machinist position can help you make a good impression and increase your chances of getting the job. Here are some tips to help you prepare for your interview:

1. Research the company

Before your interview, take some time to research the company. This will help you learn about the company’s culture, values, and products or services. You can also use this information to tailor your answers to the interviewer’s questions.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Radio Machinist. Be prepared to talk about your work history, your education, and any relevant training or certifications that you have. You should also be able to provide examples of your work that demonstrate your skills and abilities.

4. Dress professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also avoid wearing excessive jewelry or perfume.

5. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you are running late, call or email the interviewer to let them know.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Radio Machinist interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!