Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rafter Cutting Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

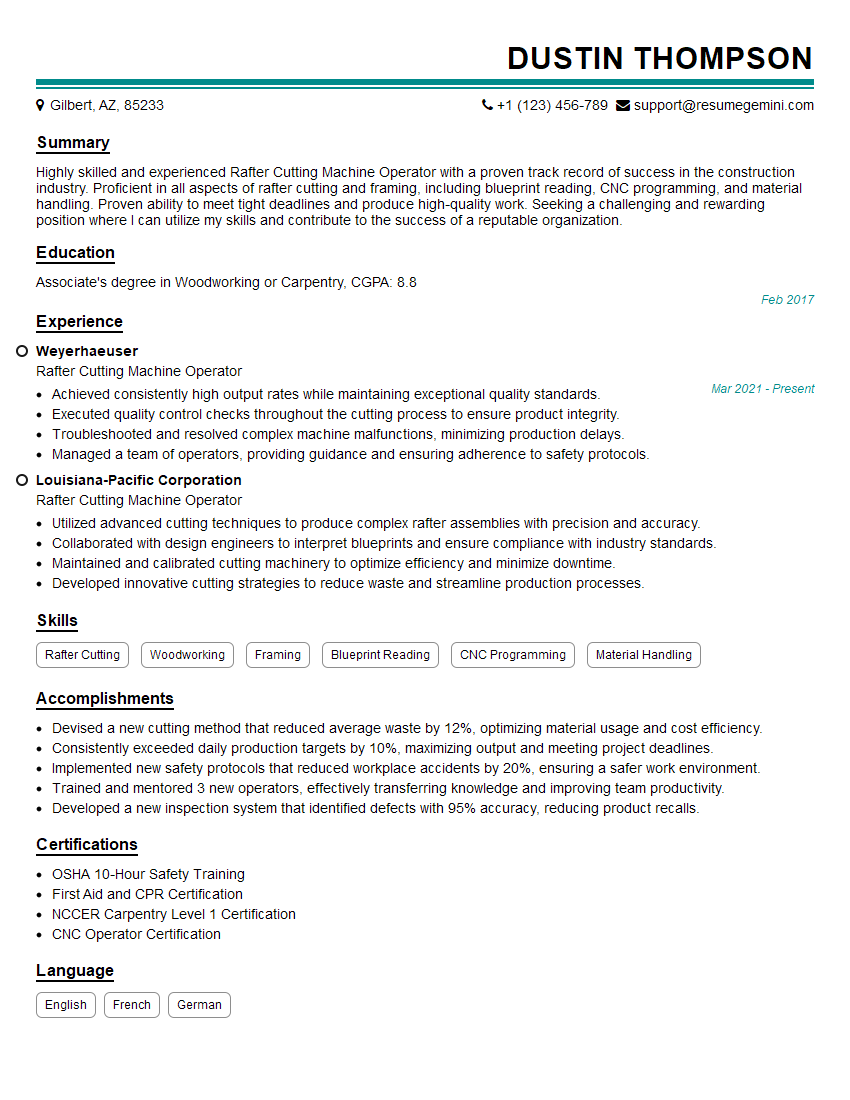

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rafter Cutting Machine Operator

1. Can you describe the process of setting up a rafter cutting machine?

- Start by determining the cutting pattern that is required.

- Secure the material to the cutting table using clamps or fasteners.

- Adjust the cutting head height and angle according to the pattern.

- Calibrate the machine to ensure accuracy.

- Set the cutting speed and other parameters based on the material being cut.

2. How do you troubleshoot common problems that occur with rafter cutting machines?

- The machine is not cutting accurately:

- Check the cutting head for any nicks or damage.

- Verify that the machine is calibrated correctly.

- Ensure that the material is secured properly.

- The machine is making excessive noise:

- Lubricate the moving parts of the machine.

- Check for any loose bolts or screws.

- Ensure that the cutting head is not dull.

3. What safety precautions must be observed when operating a rafter cutting machine?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Never operate the machine alone.

- Keep the machine clean and free of debris.

- Secure the material properly before cutting.

- Do not attempt to cut materials that are too thick or too flexible.

4. What are the different types of rafters that can be cut using a rafter cutting machine?

- Hip rafters

- Valley rafters

- Common rafters

- Jack rafters

- Collar ties

5. What are the factors that affect the cutting accuracy of a rafter cutting machine?

- The condition of the cutting head

- The calibration of the machine

- The type of material being cut

- The thickness of the material

- The cutting speed

6. What maintenance tasks are required to keep a rafter cutting machine in good working condition?

- Lubricating the moving parts

- Inspecting and sharpening the cutting head

- Cleaning the machine regularly

- Checking the calibration of the machine

- Performing any necessary repairs or replacements

7. What are the advantages of using a rafter cutting machine over manual cutting methods?

- Increased accuracy and consistency

- Faster cutting speed

- Reduced labor costs

- Improved safety

- Ability to cut complex angles and profiles

8. What material types can be processed using a rafter cutting machine?

- Wood

- Metal

- Plastic

- Composite materials

- Laminates

9. How do you ensure that the cut rafters meet the required specifications?

- Review the rafter cutting plan carefully.

- Measure and mark the material accurately.

- Set the cutting machine to the correct settings.

- Cut the rafters carefully and check their dimensions against the plan.

- Make any necessary adjustments to the cutting machine or the cutting process.

10. How do you cut rafters for a complex roof design?

- Break down the roof design into smaller sections.

- Identify the different types of rafters needed for each section.

- Use a rafter cutting machine to cut the rafters to the required lengths and angles.

- Assemble the rafters according to the roof design.

- Check the accuracy of the cuts and the overall fit of the rafters.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rafter Cutting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rafter Cutting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Rafter Cutting Machine Operator is responsible for operating and maintaining a rafter cutting machine to produce high-quality rafters for construction projects.

1. Machine Operation

• Set up and calibrate the rafter cutting machine according to job specifications

- Load and secure the lumber into the machine

- Input cutting instructions into the machine’s control panel

- Monitor the cutting process and adjust settings as needed

2. Quality Control

• Inspect the cut rafters for accuracy, dimensions, and quality

- Measure and verify the rafters meet the specified measurements

- Check for any defects or irregularities in the lumber

- Tag and label the rafters for easy identification

3. Maintenance and Troubleshooting

• Perform regular maintenance on the rafter cutting machine

- Clean and lubricate the machine’s components

- Inspect and replace worn or damaged parts

- Troubleshoot and resolve any mechanical issues

4. Safety and Compliance

• Maintain a safe and clean work area

- Wear appropriate safety gear including gloves, safety glasses, and earplugs

- Follow established safety protocols

- Comply with all applicable regulations and standards

Interview Tips

To ace an interview for a Rafter Cutting Machine Operator position, it’s crucial to highlight your relevant skills, experience, and knowledge.

1. Research the company and position

• Visit the company’s website and LinkedIn page to learn about their operations, culture, and job requirements.

- Use this information to tailor your resume and cover letter to the specific role and company.

2. Practice your answers

• Prepare for common interview questions by writing down your answers and practicing them out loud.

- Focus on demonstrating your skills and experience, using specific examples.

3. Be prepared to discuss your technical knowledge

• Review the basics of rafter cutting machine operation and maintenance.

- Be ready to explain the different types of rafter cuts, the machine’s safety features, and any troubleshooting experience you have.

4. Highlight your attention to detail

• Emphasize your ability to measure and verify measurements accurately, and your commitment to producing high-quality rafters.

- Provide examples of your quality control processes and how you ensure precision in your work.

5. Showcase your safety consciousness

• Demonstrate your understanding of safety protocols for operating rafter cutting machines.

- Explain your experience in wearing proper safety gear, following established procedures, and maintaining a clean and organized work area.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rafter Cutting Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!