Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rag Cutting Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

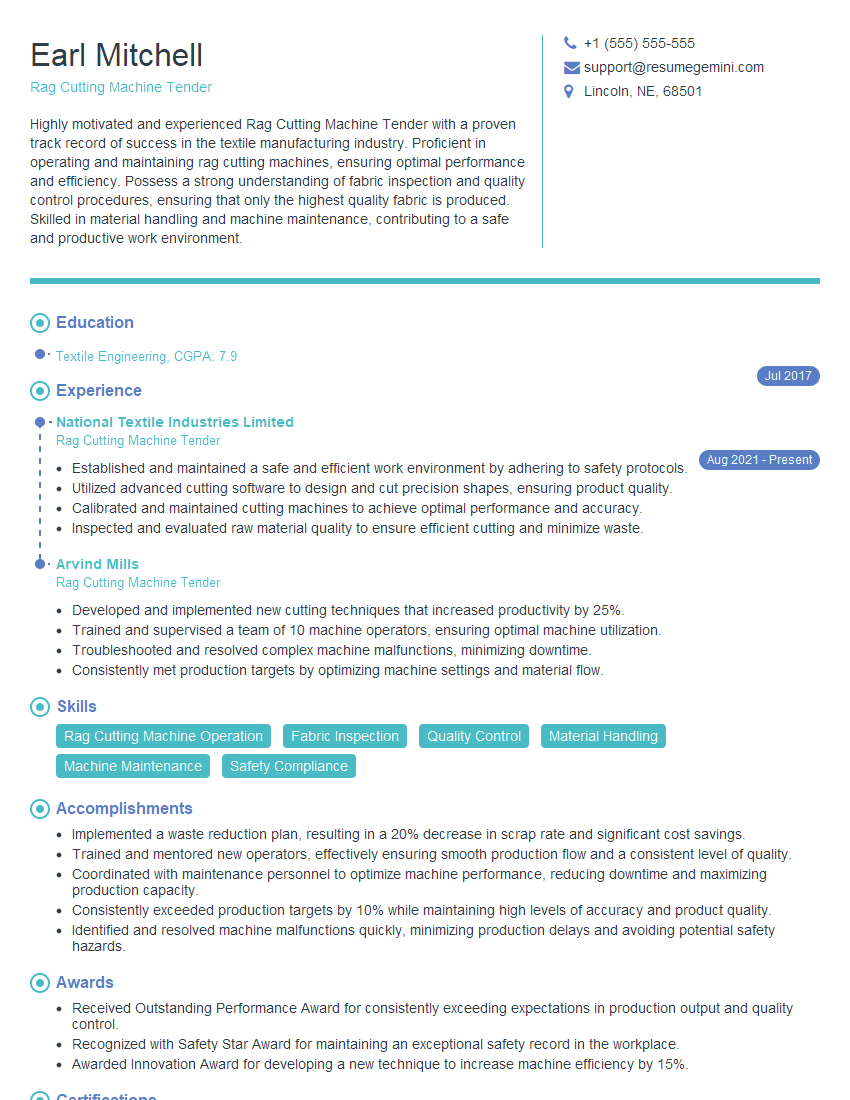

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rag Cutting Machine Tender

1. Describe the different types of rag cutting machines you have worked with and their applications.

- Horizontal band knife cutting machine: Used for cutting large volumes of fabric at high speed with precision.

- Vertical band knife cutting machine: Suitable for cutting smaller pieces of fabric with intricate shapes.

- Round knife cutting machine: Ideal for cutting circular or semi-circular pieces at high speeds.

- Rotary shear cutting machine: Used for cutting multiple layers of fabric simultaneously, resulting in a clean and precise cut.

- Guillotine cutting machine: Suitable for cutting thick or heavy fabrics with high accuracy.

2. Explain the process of loading and unloading fabric into the rag cutting machine.

- Loading fabric: Unroll the fabric and align it with the cutting blade. Secure the fabric using clamps or a vacuum system.

- Unloading fabric: Once the cutting process is complete, remove the cut fabric from the machine and roll it up.

- Follow proper safety protocols and wear appropriate protective gear to avoid injury.

3. How do you ensure the accuracy and precision of the cutting process?

- Sharp cutting blades: Regularly sharpen or replace blades to maintain sharpness.

- Accurate machine calibration: Ensure the machine is calibrated to the desired cutting length and width.

- Proper fabric loading: Load fabric smoothly and securely to prevent slippage or distortion.

- Regular maintenance: Perform routine maintenance on the machine to ensure smooth operation and accurate cuts.

4. Describe the different types of safety precautions to be taken when operating a rag cutting machine.

- Wear appropriate PPE: Safety glasses, gloves, and earplugs.

- Guardrails and interlocks: Ensure safety guardrails are in place and interlocks are functional.

- Keep hands away from cutting blade: Never reach into the cutting area while the machine is operating.

- Electrical safety: Follow proper electrical safety procedures and ensure proper grounding.

- Regular safety inspections: Inspect the machine regularly for any potential hazards or malfunctions.

5. What are the common maintenance procedures for a rag cutting machine?

- Blade sharpening or replacement: Sharpen or replace blades as needed to ensure optimal cutting performance.

- Lubrication: Regularly lubricate moving parts to prevent wear and tear.

- Cleaning: Keep the machine clean by removing fabric scraps and debris.

- Inspection and adjustment: Inspect the machine regularly for any loose parts or misalignments and adjust accordingly.

- Calibration: Periodically calibrate the machine to ensure accuracy and precision.

6. How do you troubleshoot common problems encountered with a rag cutting machine?

- Uneven cuts: Check blade sharpness, machine calibration, and fabric alignment.

- Fabric jamming: Ensure fabric is loaded properly and the machine is operating smoothly.

- Machine overheating: Check lubrication, inspect motor for any issues, and ensure adequate ventilation.

- Electrical malfunctions: Check electrical connections, fuses, and circuit breakers.

- Hydraulic leaks: Inspect hydraulic lines, connections, and seals for leaks and damage.

7. What is the importance of maintaining proper tension in the fabric during the cutting process?

- Accurate cuts: Proper tension prevents fabric from stretching or shifting, ensuring precise cutting.

- Reduced vibration: Tensioned fabric reduces vibration and ensures smooth machine operation.

- Increased blade life: Proper tension prevents the blade from snagging or tearing the fabric, extending its lifespan.

- Reduced fabric waste: Accurate cuts minimize fabric waste and optimize material utilization.

8. Explain the process of setting up a rag cutting machine for a specific cutting job.

- Blade selection: Choose the appropriate blade size and type for the fabric being cut.

- Machine calibration: Adjust the cutting length, width, and speed based on the job requirements.

- Fabric loading: Load the fabric onto the machine and secure it properly.

- Test cuts: Perform test cuts to ensure the machine is operating correctly and the cuts are accurate.

- Start production: Once test cuts are satisfactory, start production and monitor the machine’s performance.

9. Describe the different types of cutting patterns used in rag cutting machines.

- Straight cut: A simple cut made along a straight line.

- Curve cut: A cut made along a curved path.

- Zigzag cut: A cut made in a zigzag pattern to prevent fraying.

- Notched cut: A cut made with a series of notches to create a decorative edge.

- Perforated cut: A cut made with a series of holes to create a breathable or decorative effect.

10. How do you optimize cutting efficiency and minimize downtime on a rag cutting machine?

- Regular maintenance: Perform preventive maintenance to ensure optimal machine operation.

- Sharp blades: Sharpen or replace blades regularly to maintain cutting accuracy.

- Efficient fabric loading: Load fabric smoothly and securely to prevent jams and delays.

- Proper tension setting: Adjust fabric tension to prevent stretching or shifting, ensuring accurate cuts.

- Minimizing downtime: Troubleshoot and resolve common issues promptly to minimize downtime and increase productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rag Cutting Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rag Cutting Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Operating a rag cutting machine is a crucial role in the textile manufacturing industry, playing a vital part in the efficient production of various fabric products. The key responsibilities associated with this profession include:

1. Machine Operation and Maintenance

The primary task of a rag cutting machine tender is to operate the machine effectively. This involves adjusting the settings, loading the rags into the machine, ensuring smooth operation, and monitoring the cutting process. Additionally, regular maintenance and cleaning of the machine are essential to maintain its optimal performance and extend its lifespan.

- Adjusting machine settings, such as blade speed and feed rate, to achieve the desired cut quality

- Loading and unloading rags into the machine, ensuring proper alignment and avoiding jams

- Monitoring the cutting process, identifying any irregularities, and making necessary adjustments

- Performing routine maintenance, such as cleaning, lubricating, and inspecting the machine for potential issues

2. Fabric Inspection and Quality Control

Quality control is paramount in the textile industry. A rag cutting machine tender is responsible for ensuring that the cut rags meet the required specifications and standards. This involves inspecting the cut rags for any defects, such as uneven cuts, tears, or foreign objects.

- Inspecting cut rags for defects, including uneven cuts, tears, stains, or foreign materials

- Identifying and segregating defective rags to prevent contamination of the production process

- Maintaining records of fabric inspection and quality control measures

3. Production Monitoring and Optimization

Efficiency and productivity are key performance indicators for any manufacturing process. A rag cutting machine tender plays a crucial role in monitoring and optimizing production. This includes tracking the machine’s performance, identifying areas for improvement, and implementing measures to enhance efficiency.

- Tracking and recording production output, including the number of rags cut per hour

- Identifying bottlenecks and inefficiencies in the cutting process

- Implementing process improvements to increase productivity and reduce waste

4. Safety and Compliance

The textile industry involves the use of heavy machinery and hazardous materials. A rag cutting machine tender must prioritize safety and adhere to established safety protocols. This includes wearing appropriate personal protective equipment, following lockout/tagout procedures, and maintaining a clean and organized work area.

- Wearing appropriate personal protective equipment, such as gloves, safety glasses, and earplugs

- Following established safety protocols, including lockout/tagout procedures

- Maintaining a clean and organized work area to prevent accidents and ensure efficient operation

Interview Tips

Preparing thoroughly for a job interview is essential to make a positive impression and showcase your skills and qualifications. Here are some specific tips for candidates seeking to succeed in a rag cutting machine tender interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. Understanding the company’s values, products, and industry standing will demonstrate your interest and enthusiasm for the role. Additionally, reviewing the job description and identifying the key responsibilities will help you tailor your answers and highlight your relevant skills and experience.

- Visit the company’s website to learn about their history, mission, and products or services

- Read industry news and articles to stay updated on the latest trends and developments

- Contact your network or reach out to current or former employees for insights into the company culture and work environment

2. Practice Common Interview Questions

Preparing for common interview questions will boost your confidence and enable you to articulate your answers clearly and concisely. Practice answering questions related to your technical skills, experience with rag cutting machines, and understanding of safety protocols. Additionally, prepare questions to ask the interviewer, demonstrating your engagement and interest in the position and the company.

- Describe your experience operating rag cutting machines, including the types of machines you have worked with

- Explain how you ensure the quality of the cut rags and maintain production efficiency

- Discuss your knowledge of safety protocols and procedures in a manufacturing environment

3. Highlight your Skills and Qualifications

During the interview, emphasize your skills and qualifications that align with the key responsibilities of a rag cutting machine tender. Quantify your accomplishments whenever possible, using specific examples to demonstrate your proficiency in machine operation, fabric inspection, production monitoring, and safety compliance.

- Quantify your experience in terms of the number of rags cut per hour or the percentage of defective rags identified and removed

- Provide examples of how you have improved production efficiency or reduced waste in previous roles

- Highlight any certifications or training you have received in rag cutting machine operation or safety protocols

4. Be Enthusiastic and Professional

A positive and enthusiastic attitude can make a significant impact during an interview. Demonstrate your passion for the textile industry and your eagerness to contribute to the company’s success. Maintain a professional demeanor throughout the interview, dress appropriately, and be respectful of the interviewer’s time.

- Start the interview with a firm handshake and make eye contact

- Speak clearly and confidently, and actively listen to the interviewer’s questions

- Ask thoughtful questions at the end of the interview

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rag Cutting Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!