Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Rail Bonder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Rail Bonder so you can tailor your answers to impress potential employers.

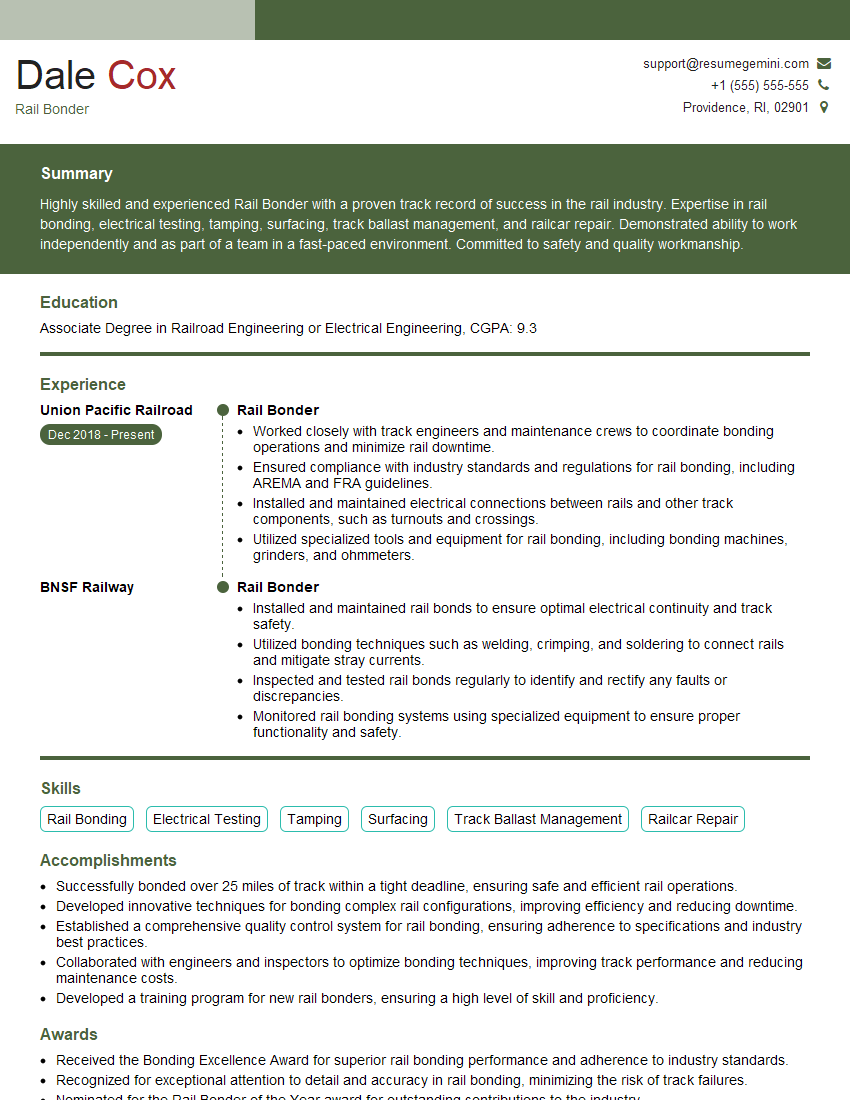

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rail Bonder

1. Describe the process of bonding rails using the thermite welding method?

- Preparatory work: Ensure the rails are clean and free of rust or debris. Use a grinding tool to remove any dirt or impurities. Align the rails properly.

- Preheat the rails: Use a preheating torch to raise the temperature of the rails to around 1,200°C. This helps to remove moisture and create a suitable environment for welding.

- Place the thermite crucible: Position the thermite crucible over the joint between the rails. The crucible contains a mixture of iron oxide and aluminum powder.

- Ignite the thermite: Start the thermite reaction by igniting the magnesium strip or cartridge. This initiates a chemical reaction that produces molten iron.

- Pour the molten iron: Once the thermite reaction is complete, pour the molten iron into the mold surrounding the rail joint. The molten iron flows between the rails and the mold, creating a strong bond.

- Remove the mold: After the molten iron has solidified, remove the mold to reveal the welded rail joint.

2. What are the key factors to consider when selecting the appropriate bonding method for rails?

Material type:

- Identify the specific type of steel being used for the rails.

- Different materials may require different bonding methods.

Track conditions:

- Evaluate the environmental conditions where the rails will be used.

- Consider factors such as temperature, humidity, and traffic load.

Bonding location:

- Determine the accessibility and constraints of the bonding site.

- Certain methods may require specialized equipment or access to power.

Bonding requirements:

- Establish the desired strength and durability requirements for the bond.

- Different methods offer varying levels of bonding strength.

Cost and efficiency:

- Compare the costs associated with different bonding methods.

- Consider the efficiency of each method, including time and resources required.

3. Explain the safety precautions that must be taken when using bonding machines?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Ensure the bonding machine is properly grounded to prevent electrical shock.

- Maintain a safe work area free of tripping hazards, debris, and flammable materials.

- Follow the manufacturer’s instructions for operating the bonding machine.

- Never leave the bonding machine unattended while in operation.

- Allow the bonding machine to cool down before handling or storing it.

4. Describe the different types of rail bonds and their applications?

Insulated rail joints:

- Used to electrically isolate sections of track.

- Prevent stray currents and reduce electrolysis.

Welded rail joints:

- Create a continuous electrical and mechanical connection between rails.

- Reduce track maintenance and improve ride quality.

Bolted rail joints:

- Provide a temporary or semi-permanent connection between rails.

- Used in areas where welding is not feasible or for temporary track layouts.

Expansion joints:

- Allow for the expansion and contraction of rails due to temperature changes.

- Prevent buckling and maintain track integrity.

5. What are the common defects that can occur during rail bonding and how can they be prevented?

Cold welds:

- Caused by insufficient rail heating.

- Can lead to weak bonds and track failures.

- Prevention: Ensure proper preheating and use a bonding method suitable for cold weather conditions.

Gaps in the bond:

- Caused by improper alignment of rails or insufficient bond material.

- Compromises the electrical and mechanical integrity of the bond.

- Prevention: Ensure precise rail alignment and use the appropriate bonding equipment and material.

Porosity:

- Caused by trapped air or gas during bonding.

- Weakens the bond and can lead to premature failure.

- Prevention: Use proper bonding techniques, such as vacuum bonding or air release devices.

6. Explain the importance of rail bonding for electrical signaling systems?

- Ensures a continuous electrical path for signaling currents.

- Improves the reliability and safety of signaling systems.

- Reduces the risk of false signals or signal failures.

- Facilitates the transmission of data and communication signals along the track.

7. Describe the advantages and disadvantages of using ultrasonic rail bonding?

Advantages:

- Produces strong and durable welds.

- Can be used in remote or inaccessible areas.

- Less time-consuming than traditional welding methods.

Disadvantages:

- Requires specialized equipment and skilled operators.

- Can be affected by adverse weather conditions.

- May produce noise and vibrations during operation.

8. What are the latest advancements in rail bonding technology?

- Automated bonding machines for increased efficiency and accuracy.

- Innovative bonding materials for improved strength and durability.

- Non-destructive testing methods for faster and more reliable weld inspections.

- Data analytics to optimize bonding processes and predict potential issues.

9. Discuss the challenges of bonding rails in high-speed railway systems?

- Maintaining electrical continuity at high operating speeds.

- Ensuring bond strength under dynamic loading and vibration.

- Minimizing noise and electromagnetic interference generated by bonding.

- Adapting bonding techniques to accommodate specialized rail profiles and designs.

10. How do you stay up-to-date with the latest developments in rail bonding?

- Attend industry conferences and seminars.

- Read technical journals and research papers.

- Network with professionals in the field.

- Participate in training and certification programs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rail Bonder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rail Bonder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Rail Bonder

A Rail Bonder plays a crucial role in maintaining and repairing railway tracks, ensuring the safety and efficiency of train operations. Their primary responsibilities include:

1. Rail Bonding

The most important task of a Rail Bonder is to install and maintain electrical bonds between rails. These bonds ensure that there is a continuous electrical path along the track, which is essential for the proper functioning of signaling systems and to prevent electrical hazards.

- Install and maintain insulated joints to isolate electrical sections of the track.

- Inspect existing bonds for damage or deterioration, and repair or replace them as necessary.

2. Rail Grinding

Rail Bonders also perform rail grinding operations to remove accumulated metal from the railhead. This process helps to restore the rail’s original profile, improve train traction, and extend the life of the rails.

- Operate rail grinding machines to remove excess metal and smooth the rail surface.

- Monitor the grinding process to ensure the desired results are achieved.

3. Rail Inspection

Rail Bonders are responsible for inspecting rails for defects and damage. They use specialized tools and techniques to identify cracks, wear, and other problems that could compromise the safety of the track.

- Conduct visual inspections of rails, joints, and other track components.

- Use ultrasonic or other non-destructive testing methods to detect hidden defects.

4. Track Maintenance

In addition to bonding, grinding, and inspection, Rail Bonders may also assist with other track maintenance tasks. These tasks could include:

- Replacing or repairing rail ties and fasteners.

- Adjusting track alignment and gauge.

- Clearing track debris and vegetation.

Interview Preparation Tips for Rail Bonders

To ace the interview for a Rail Bonder position, candidates should prepare thoroughly by following these tips:

1. Research the Company and Position

Before the interview, candidates should research the railway company, its values, and the specific requirements of the Rail Bonder role. This information can be found on the company’s website, industry publications, or through networking contacts.

2. Highlight Relevant Skills and Experience

Candidates should emphasize their skills and experience that are directly related to the job responsibilities. This includes experience in rail bonding, grinding, inspection, and track maintenance. They should also highlight their knowledge of railway safety regulations and procedures.

- Showcase any certifications or training programs related to rail bonding, grinding, or inspection.

- Provide specific examples of projects or tasks where you successfully completed similar responsibilities.

3. Prepare for Technical Questions

Interviewers may ask technical questions to assess the candidate’s knowledge of rail bonding and track maintenance. These questions could cover topics such as:

- Different types of rail bonds and their applications.

- Methods used for rail grinding and the importance of rail profiling.

- Non-destructive testing techniques for rail inspection.

4. Demonstrate Teamwork and Safety Awareness

Rail Bonders often work as part of a team and must be able to collaborate effectively with others. Interviewers will be looking for candidates who demonstrate strong teamwork skills and a commitment to safety. Candidates should highlight their experience working in team environments and their understanding of safety protocols.

- Share examples of situations where you successfully collaborated with colleagues to complete a project.

- Discuss your knowledge of railway safety regulations and how you apply them in your work.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Rail Bonder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Rail Bonder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.