Are you gearing up for a career in Rail Car Painter/Sandblaster? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rail Car Painter/Sandblaster and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

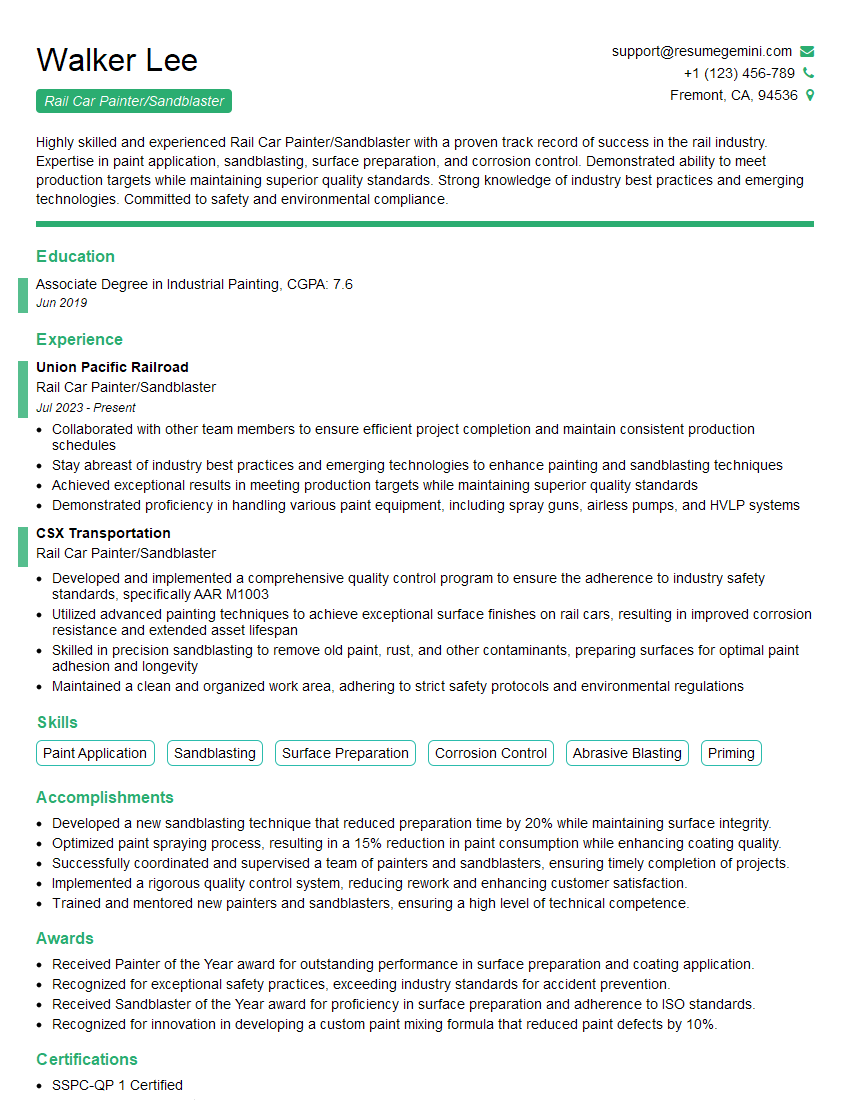

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rail Car Painter/Sandblaster

1. Describe the steps involved in preparing a rail car for painting.

The preparation of a rail car for painting involves several steps to ensure a smooth and durable finish:

- Surface Inspection: Inspect the car for any imperfections, rust, or damage.

- Cleaning: Remove dirt, grease, and debris using high-pressure washers or solvents.

- Sandblasting: Remove old paint, rust, and surface contaminants using abrasive media and compressed air.

- Masking: Protect areas that should not be painted, such as windows, electrical components, and decals.

- Priming: Apply a primer coat to enhance paint adhesion and corrosion resistance.

2. What types of paints and coatings are commonly used for rail cars?

Water-Based Paints:

- Environmentally friendly and less toxic.

- Quick drying and easy to clean up.

Solvent-Based Paints:

- Provide a durable and high-gloss finish.

- Longer drying time and require proper ventilation.

Electrostatic Coatings:

- Powder coatings applied with an electrostatic charge.

- Provide superior corrosion resistance and a smooth finish.

Two-Component Coatings:

- Consist of a resin and a hardener mixed before application.

- Offer excellent resistance to wear, chemicals, and UV radiation.

3. Explain the purpose and process of sandblasting in rail car maintenance.

Sandblasting is a crucial process in rail car maintenance as it removes old paint, rust, and other contaminants from the metal surfaces:

- Surface Preparation: Sandblasting cleans the surface, creating a rougher texture for better paint adhesion.

- Rust Removal: Abrasive media effectively removes rust, preventing further corrosion and improving paint longevity.

- Contaminant Removal: Sandblasting removes dirt, grease, and other foreign matter, ensuring a clean and durable surface.

- Profile Creation: It creates a consistent surface profile, enhancing paint adhesion and reducing the risk of peeling.

4. Describe the safety measures and personal protective equipment (PPE) required for rail car painting and sandblasting.

Safety is paramount in rail car painting and sandblasting:

- PPE: Wear protective clothing, respirator, goggles, earplugs, and gloves to prevent exposure to chemicals, fumes, and abrasive materials.

- Ventilation: Ensure proper ventilation to avoid inhaling harmful vapors and dust.

- Containment: Set up containment measures to prevent paint overspray and sandblasting debris from spreading.

- Grounding: Ground all equipment and wear anti-static shoes to prevent electrical hazards.

- Emergency Preparedness: Have fire extinguishers, first aid kits, and emergency protocols readily available.

5. What techniques do you use to ensure even and consistent paint application?

To achieve an even and consistent paint finish, I employ the following techniques:

- Surface Preparation: Thoroughly clean and prepare the surface to promote paint adhesion.

- Proper Spray Technique: Use the correct spray gun settings and hold it at the optimal distance from the surface.

- Multiple Thin Coats: Apply multiple thin coats rather than one thick coat to prevent runs and sagging.

- Overlapping Strokes: Overlap each spray stroke by 50-75% to ensure even coverage.

- Wet-on-Wet Application: Apply subsequent coats while the previous coat is still wet to enhance blending.

6. How do you handle defects and imperfections in the paint finish?

To address defects and imperfections in the paint finish, I follow these steps:

- Identification: Inspect the surface and identify the type and location of the defect.

- Repair: Depending on the defect, I sand, fill, or touch up the area to restore the smooth finish.

- Repainting: If necessary, I repaint the affected area or the entire surface to match the existing color and sheen.

- Inspection: I conduct a final inspection to ensure the defect has been fully resolved and the finish is uniform.

7. What troubleshooting techniques do you use if the paint does not adhere properly to the rail car surface?

To resolve paint adhesion issues, I employ the following troubleshooting techniques:

- Surface Inspection: Check the surface for any contaminants, such as oil, grease, or moisture, that may hinder adhesion.

- Primer Adhesion: Ensure that the primer is compatible with the paint and the rail car surface.

- Proper Preparation: Verify that the surface has been properly prepared through sandblasting or other cleaning methods.

- Environmental Conditions: Check if the application conditions, such as temperature and humidity, are within the recommended range.

- Paint Compatibility: Confirm that the paint is compatible with the substrate and the primer used.

8. How do you ensure the color matching of repaired or repainted areas with the existing paint finish?

To achieve optimal color matching, I utilize various techniques:

- Paint Color Code: Refer to the rail car’s paint color code or consult with the manufacturer for the exact paint formula.

- Sample Matching: Create a sample of the existing paint finish and compare it to the new paint to ensure a close match.

- Test Application: Apply the new paint to an inconspicuous area to test the color and sheen before proceeding with the full repair.

- Blending: Use blending techniques, such as overlapping and feathering, to transition between the repaired area and the existing finish.

- Clear Coat Application: Apply a clear coat over the repaired area to enhance durability and protect the color match.

9. How do you prioritize and manage your time effectively when working on multiple rail car painting projects?

To effectively manage my time and prioritize multiple projects, I follow these strategies:

- Project Assessment: Evaluate each project’s scope, deadlines, and resources required.

- Task Prioritization: Prioritize tasks based on their urgency and impact on the overall project.

- Schedule Management: Create a realistic timeline and allocate time for each task accordingly.

- Task Delegation: Delegate tasks to team members when appropriate to optimize efficiency.

- Regular Communication: Stay in touch with team members and supervisors to ensure timely updates and address any challenges.

10. Describe a situation where you faced a technical challenge while painting a rail car and how you resolved it.

Once, while painting a rail car, I encountered an issue where the paint was bubbling and peeling. I identified that the surface had not been properly prepared, leading to poor paint adhesion. To resolve this, I thoroughly sanded the surface, applied a compatible primer, and repainted the area. By addressing the root cause, I ensured a durable and visually appealing finish.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rail Car Painter/Sandblaster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rail Car Painter/Sandblaster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rail Car Painters/Sandblasters are responsible for the upkeep and maintenance of rail cars and other related equipment. They play a crucial role in ensuring the safety and efficiency of railway operations.

1. Painting and Surface Preparation

Preparing surfaces for painting, including sanding, cleaning, and masking.

- Applying paint using various techniques such as spray painting, brush painting, or roller painting.

- Ensuring proper drying and curing of paint.

2. Sandblasting

Preparing surfaces for painting or other treatments by removing rust, dirt, and debris using sandblasting equipment.

- Operating sandblasting equipment safely and effectively.

- Selecting appropriate abrasives and blast pressures for specific surfaces.

3. Inspecting and Repairing

Inspecting rail cars for damage, wear and tear, and corrosion.

- Repairing minor damage and dents using appropriate tools and techniques.

- Preparing damage reports and recommending necessary repairs.

4. Safety and Compliance

Adhering to safety protocols and industry standards.

- Wearing personal protective equipment and following safety procedures.

- Ensuring compliance with environmental regulations related to painting and sandblasting operations.

Interview Tips

Preparing for an interview for a Rail Car Painter/Sandblaster position requires careful preparation and a solid understanding of the job’s responsibilities.

1. Research the Company and Industry

Familiarize yourself with the company’s history, values, and operations.

- Research the railway industry, including current trends and best practices.

- Stay updated on advancements in painting and sandblasting technologies.

2. Highlight Relevant Experience and Skills

Emphasize your experience in painting, sandblasting, and surface preparation.

- Quantify your accomplishments and provide specific examples of your work.

- Showcase your attention to detail, problem-solving abilities, and commitment to safety.

3. Prepare for Technical Questions

Anticipate questions about painting techniques, sandblasting equipment, and industry standards.

- Review common types of paint and their applications.

- Familiarize yourself with different types of sandblasting abrasives and their uses.

- Study industry regulations and best practices related to painting and sandblasting.

4. Demonstrate Motivation and Enthusiasm

Express your interest in the role and the railway industry.

- Explain why you are passionate about painting and sandblasting.

- Share your career goals and how this position aligns with them.

- Highlight your willingness to learn and grow within the organization.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rail Car Painter/Sandblaster role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.