Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Rail Car Repairer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Rail Car Repairer so you can tailor your answers to impress potential employers.

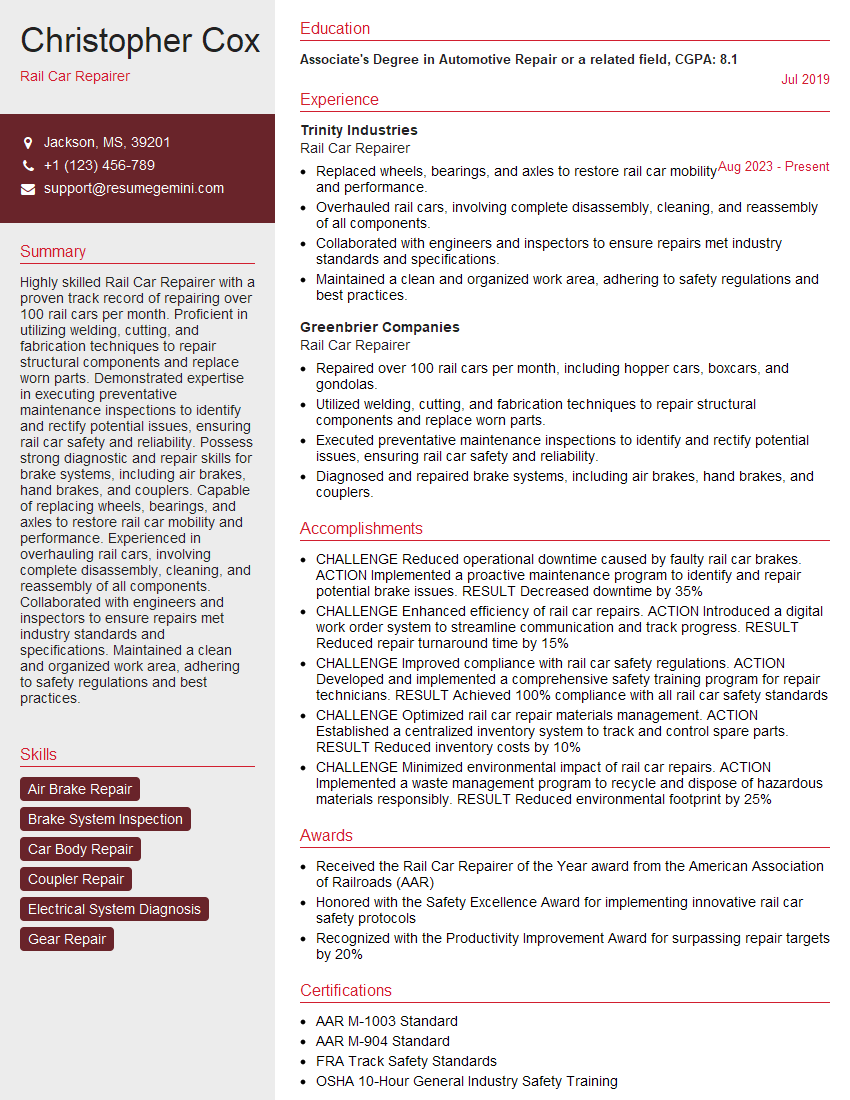

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rail Car Repairer

1. Explain the process of troubleshooting a malfunctioning rail car component?

- Begin by identifying the symptoms of the malfunction.

- Gather information about the component’s operation and maintenance history.

- Perform a visual inspection of the component and its surroundings.

- Use diagnostic tools to test the component’s functionality.

- Analyze the test results to identify the root cause of the malfunction.

- Develop and implement a repair plan.

- Test the component to ensure it is functioning properly.

2. How would you approach repairing a damaged rail car body panel?

Assess the damage

- Determine the extent of the damage, including the size, shape, and location.

- Inspect the surrounding area for additional damage.

- Identify the type of material used in the panel.

Prepare the repair area

- Clean the damaged area and remove any debris or corrosion.

- Mask off the surrounding area to protect it from damage.

Repair the panel

- Use the appropriate tools and techniques to repair the panel, such as welding, riveting, or bonding.

- Ensure that the repair is strong and durable.

Finish the repair

- Remove the masking and clean the repaired area.

- Apply a protective coating to the repair to prevent corrosion.

3. Describe the different types of welding techniques used in rail car repair and when each technique is appropriate?

- Arc welding is a type of welding that uses an electric arc to melt the metal together. It is a versatile welding process that can be used to weld a variety of metals, including steel, aluminum, and stainless steel.

- MIG welding (metal inert gas welding) is a type of arc welding that uses a shielding gas to protect the weld from contamination. It is a popular welding process for welding thin metals, such as sheet metal.

- TIG welding (tungsten inert gas welding) is a type of arc welding that uses a tungsten electrode to create the arc. It is a precision welding process that is used for welding high-quality welds.

- Spot welding is a type of welding that uses two electrodes to create a weld. It is a fast and efficient welding process that is used for welding thin metals, such as sheet metal.

4. What are the safety precautions that must be taken when working on a rail car?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a hard hat.

- Be aware of your surroundings and identify any potential hazards.

- Follow all safety procedures and protocols.

- Use tools and equipment properly.

- Never work on a rail car that is in motion.

- Be aware of the electrical hazards associated with rail cars.

- Never work on a rail car that is energized.

5. What are the different types of rail car trucks and how do they differ in their design and function?

- Bolsterless trucks are a type of rail car truck that does not have a bolster. Instead, the car body rests directly on the truck side frames.

- Center sill trucks are a type of rail car truck that has a center sill that runs the length of the truck. The car body rests on the center sill.

- Articulated trucks are a type of rail car truck that is designed to allow the car body to articulate, or bend. This allows the car to navigate curves more easily.

6. How would you diagnose and repair a brake system problem on a rail car?

Diagnose the problem

- Listen for any unusual noises coming from the brake system.

- Check the brake pads and shoes for wear or damage.

- Inspect the brake lines and hoses for leaks or damage.

- Test the brake system using a brake tester.

Repair the problem

- Replace any worn or damaged brake pads or shoes.

- Repair or replace any leaking or damaged brake lines or hoses.

- Adjust the brake system to ensure that it is functioning properly.

7. What are the different types of rail car couplers and how do they differ in their design and function?

- Automatic couplers are a type of rail car coupler that can be coupled and uncoupled automatically. They are used on most freight cars.

- Semi-automatic couplers are a type of rail car coupler that can be coupled automatically, but must be uncoupled manually. They are used on some passenger cars and locomotives.

- Manual couplers are a type of rail car coupler that must be coupled and uncoupled manually. They are used on some older rail cars.

8. How would you inspect and maintain a rail car wheel and axle assembly?

Inspect the wheel

- Check the wheel for cracks, wear, and other damage.

- Measure the wheel diameter to ensure that it is within specifications.

Inspect the axle

- Check the axle for cracks, wear, and other damage.

- Measure the axle diameter to ensure that it is within specifications.

Maintain the wheel and axle assembly

- Lubricate the wheel and axle assembly regularly.

- Tighten the wheel nuts to the proper torque.

- Inspect the wheel and axle assembly regularly for signs of wear or damage.

9. What are the different types of rail car bearings and how do they differ in their design and function?

- Roller bearings are a type of rail car bearing that uses rollers to reduce friction between the wheel and the axle.

- Ball bearings are a type of rail car bearing that uses balls to reduce friction between the wheel and the axle.

- Tapered roller bearings are a type of rail car bearing that uses tapered rollers to reduce friction between the wheel and the axle.

10. How would you troubleshoot a malfunctioning electrical system on a rail car?

Identify the problem

- Check for any obvious signs of damage, such as loose wires or burned-out components.

- Use a multimeter to test the voltage and continuity of the electrical system.

- Inspect the electrical schematic to identify the source of the problem.

Repair the problem

- Replace any damaged wires or components.

- Tighten any loose connections.

- Adjust the voltage or continuity of the electrical system as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rail Car Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rail Car Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rail Car Repairers, also known as Railcar Mechanics, play a crucial role in ensuring the safe and efficient operation of trains by performing various maintenance and repair tasks. Their key responsibilities include:Inspecting and Diagnosing Rail Cars

1. Conducting Thorough Inspections

Rail Car Repairers conduct routine and scheduled inspections of rail cars, including locomotives, passenger cars, and freight cars.

- Visually examining the exterior and interior of rail cars for any signs of damage or wear

- Using specialized tools and equipment to diagnose faults and identify potential issues

2. Troubleshooting Rail Car Systems

When a rail car experiences a malfunction or issue, Rail Car Repairers are responsible for diagnosing the problem and determining the best course of action.

- Analyzing error codes and system logs to identify potential causes of the issue

- Testing components and systems to isolate the source of the problem

3. Dismantling and Reassembling Rail Cars

In some cases, it may be necessary to dismantle or disassemble rail cars for repairs or maintenance.

- Following established procedures to safely remove and replace components such as wheels, brakes, and engines

- Inspecting and repairing individual components before reassembling the rail car

4. Maintaining and Repairing Rail Car Components

Rail Car Repairers are proficient in maintaining and repairing a wide range of rail car components, including:

- Replacing worn or damaged parts, such as brake pads, wheels, and electrical wiring

- Adjusting and calibrating systems to ensure optimal performance

Interview Tips

Preparing thoroughly for a Rail Car Repairer interview is essential to showcase your skills and make a positive impression on the hiring manager. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the rail company and the specific Rail Car Repairer position you are applying for.

- Learn about the company’s history, values, and recent projects

- Review the job description carefully to identify the key requirements and responsibilities

2. Highlight Your Skills and Experience

During the interview, emphasize your relevant skills and experience as a Rail Car Repairer.

- Provide specific examples of your ability to diagnose and repair rail car systems

- Highlight your experience in maintaining and repairing rail car components

3. Demonstrate Safety and Attention to Detail

Safety is paramount in the rail industry. In your interview, communicate your strong commitment to safety and attention to detail.

- Share examples of how you have followed safety protocols and regulations in your previous roles

- Discuss your systematic approach to inspecting and repairing rail cars

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company.

- Inquire about the company’s current projects and future plans

- Ask about the specific challenges and opportunities involved in the Rail Car Repairer role

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rail Car Repairer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.