Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Rail Car Welder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Rail Car Welder so you can tailor your answers to impress potential employers.

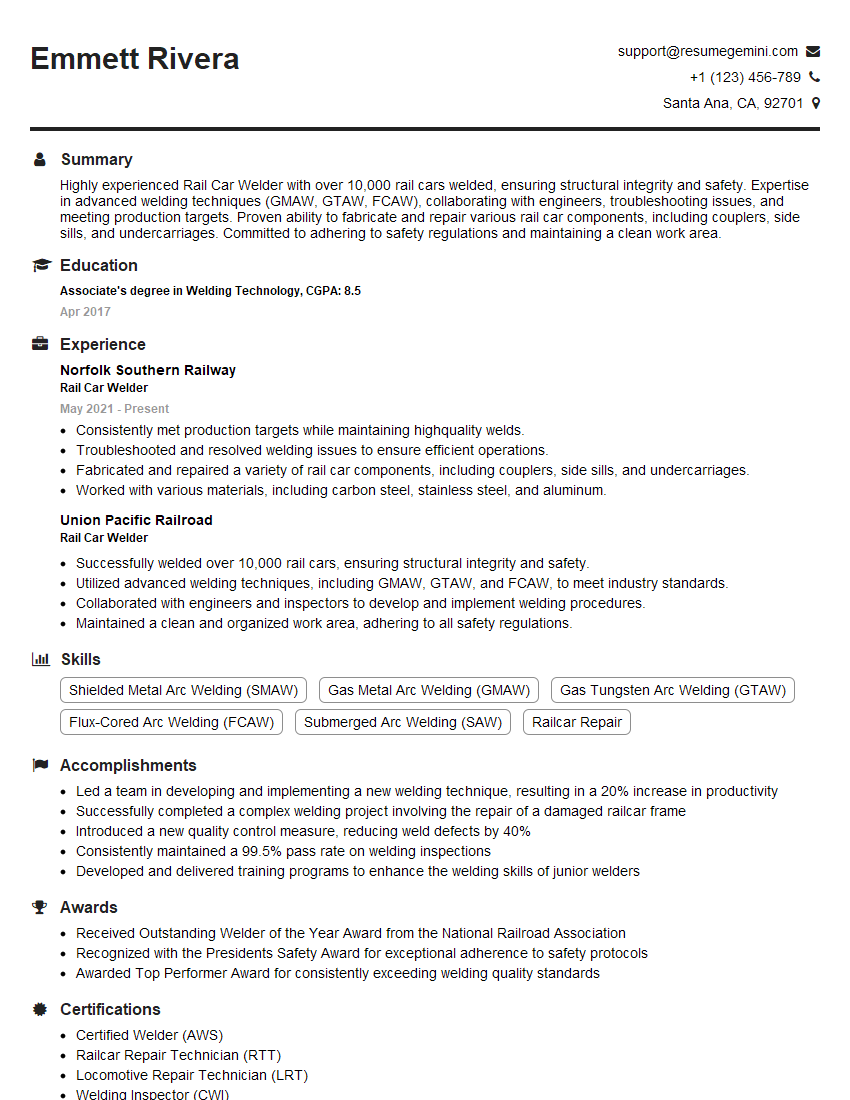

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rail Car Welder

1. Explain the different types of welding procedures used in rail car manufacturing.

- Gas Metal Arc Welding (GMAW) – This is a semi-automatic or automatic welding process that uses a shielding gas to protect the weld area from the atmosphere. It is commonly used for welding thin materials and is characterized by its high welding speed and relatively low heat input.

- Gas Tungsten Arc Welding (GTAW) – Also known as TIG welding, GTAW is a manual welding process that uses a tungsten electrode and a shielding gas to create a weld. It is often used for welding thicker materials and produces high-quality welds with minimal distortion.

- Submerged Arc Welding (SAW) – SAW is an automatic or semi-automatic welding process that uses a blanket of granular flux to shield the weld area. It is commonly used for welding large, thick sections and is known for its high productivity and deep penetration.

- Resistance Spot Welding (RSW) – RSW is a resistance welding process that uses two electrodes to apply pressure and an electric current to create a weld. It is commonly used for welding sheet metal and is characterized by its short welding time and high production rate.

2. How do you ensure that your welds meet the required standards and specifications?

Quality Control Procedures

- Visual inspection

- Dimensional measurement

- Non-destructive testing (NDT) such as ultrasonic testing, radiographic testing, and magnetic particle testing

- Destructive testing (DT) such as tensile testing, bend testing, and impact testing

Maintaining Certifications

- American Welding Society (AWS) certification

- Client-specific qualifications and certifications

- Regular refresher training and re-certification

3. Describe the welding safety precautions that you must adhere to.

- Wear appropriate personal protective equipment (PPE) such as welding helmet, gloves, flame-resistant clothing, and safety glasses.

- Ensure proper ventilation to prevent the inhalation of welding fumes.

- Inspect equipment regularly and maintain it in good working condition.

- Handle and store welding materials safely, including cylinders, electrodes, and fluxes.

- Follow established safety protocols for hot work, confined spaces, and working at heights.

- Be aware of potential hazards such as electrical shock, arc flash, and fire.

4. What are the challenges you have faced in your previous role as a Rail Car Welder?

- Working with different types of materials and thicknesses.

- Meeting tight production deadlines while maintaining quality standards.

- Troubleshooting and resolving welding defects.

- Working in confined spaces or awkward positions.

- Adapting to new welding technologies and procedures.

- Interpreting and following complex welding specifications and drawings.

5. How do you stay updated on the latest welding technologies and best practices?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Participate in online forums and discussion groups.

- Receive training from equipment manufacturers and welding suppliers.

- Stay informed about industry standards and regulations, such as AWS D1.1.

6. What are the qualities that make a successful Rail Car Welder?

- Strong technical skills and knowledge of welding processes.

- Excellent hand-eye coordination and manual dexterity.

- Attention to detail and precision.

- Ability to work independently and as part of a team.

- Physical stamina and ability to work in various positions.

- Commitment to safety and quality.

- Willingness to learn and adapt to new technologies.

7. Can you describe the process of welding a rail car frame?

Step 1: Preparation

- Clean and prepare the surfaces to be welded.

- Tack weld the components to hold them in place.

Step 2: Welding

- Select the appropriate welding process, welding rod, and shielding gas.

- Weld the components together using the specified welding parameters.

Step 3: Post-Welding

- Grind and finish the welds to remove any imperfections.

- Inspect the welds to ensure they meet the required standards.

8. What are the common welding defects that you encounter and how do you prevent them?

Common Welding Defects:

- Porosity

- Incomplete fusion

- Undercut

- Cracking

- Warping

Prevention Techniques:

- Proper joint preparation

- Correct welding parameters

- Shielding the weld area

- Minimizing heat input

- Using proper welding techniques

9. What are the maintenance tasks that you perform on welding equipment?

- Clean and inspect welding torches, nozzles, and tips.

- Check and replace welding cables and hoses.

- Lubricate moving parts.

- Calibrate welding equipment regularly.

- Perform routine maintenance on welding power sources, such as cleaning and replacing filters.

10. How do you handle working with different welding materials, such as steel, aluminum, and stainless steel?

- Understand the properties and characteristics of each material.

- Select the appropriate welding process, welding rod, and shielding gas for each material.

- Adjust welding parameters to optimize weld quality.

- Follow specific welding procedures and techniques for each material.

- Stay informed about industry best practices and recommendations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rail Car Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rail Car Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A rail car welder is a highly skilled professional who is responsible for welding rail cars and their components. They must have a strong understanding of welding techniques and safety procedures, and be able to work independently and as part of a team.

1. Welding

Rail car welders use a variety of welding techniques to join metal components, including MIG welding, TIG welding, and arc welding. They must be able to weld in a variety of positions, including overhead and on their side.

- Weld rail car components, such as frames, panels, and doors

- Repair damaged rail cars

2. Fabrication

In addition to welding, rail car welders may also be responsible for fabricating rail car components. This involves cutting, shaping, and assembling metal parts. They must be able to read and interpret blueprints and drawings.

- Fabricate new rail car components

- Modify existing rail car components

3. Inspection

Rail car welders must inspect their work to ensure that it meets safety standards. They must be able to identify and correct any defects.

- Inspect welds for defects

- Repair or replace defective welds

4. Maintenance

Rail car welders may also be responsible for maintaining welding equipment and tools. They must be able to troubleshoot and repair problems. They also must follow and adhere to safety standards and regulations.

- Maintain welding equipment and tools

- Troubleshoot and repair welding problems

Interview Tips

Preparing for an interview for a rail car welder position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you prepare:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor. You can also find information about the position in the job description.

- Visit the company’s website to learn about their history, mission, and values.

- Read the job description carefully and identify the key skills and experience required.

- Research the industry to learn about the latest trends and technologies.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to practice your answers to these questions so that you can deliver them confidently and clearly.

- Use the STAR method to answer interview questions.

- Prepare specific examples of your skills and experience that are relevant to the job.

- Practice your answers with a friend or family member.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time and be prepared to answer questions about your experience and qualifications.

- Wear a suit or business casual attire.

- Be punctual and arrive at the interview location 10-15 minutes early.

- Bring a portfolio of your work or a resume and references.

4. Be enthusiastic and ask questions

Employers are looking for candidates who are enthusiastic about the position and the company. Be sure to express your interest in the job and ask questions about the company and the position. This shows that you are engaged and interested in the opportunity.

- Show your enthusiasm for the position and the company.

- Ask thoughtful questions about the company, the position, and the industry.

- Be prepared to talk about your skills and experience.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rail Car Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!