Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Railroad Brake Repairer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

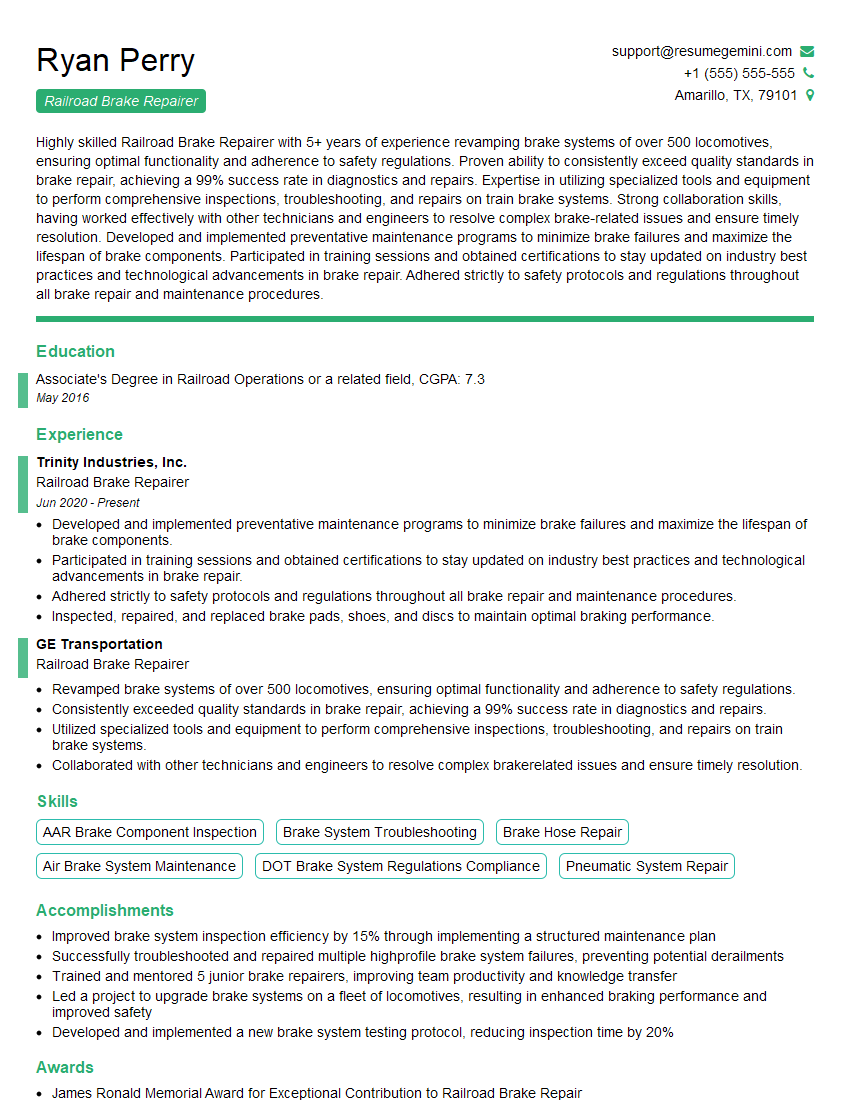

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Railroad Brake Repairer

1. What are the key components of a railroad brake system?

The key components of a railroad brake system include:

- Brake shoes

- Brake cylinders

- Brake levers

- Air compressor

- Air reservoirs

- Brake pipes

- Brake valves

2. Explain the purpose and operating principle of a brake cylinder.

Principle of Operation

- Brake cylinders are used to convert compressed air into mechanical force that actuates the brake shoes.

- When compressed air is admitted into the brake cylinder, it exerts force on a piston, which in turn pushes a piston rod.

- The piston rod is connected to the brake levers, which apply pressure to the brake shoes and bring them into contact with the wheels.

Purpose of Brake Cylinder

- To provide the necessary force to apply the brake shoes to the wheels.

- To ensure that the brake shoes are applied evenly and with the correct amount of force.

3. What are the different types of brake shoes used in railroad brake systems?

The different types of brake shoes used in railroad brake systems include:

- Composite brake shoes: Made of a combination of metal and non-metallic materials, providing good braking performance and wear resistance.

- Cast iron brake shoes: Made of high-strength cast iron, offering durability and resistance to thermal cracking.

- Disc brake pads: Similar to those used in automotive brakes, disc brake pads are used in some newer railroad brake systems.

4. Describe the procedure for inspecting and testing brake shoes.

The procedure for inspecting and testing brake shoes includes:

- Visual inspection: Check for cracks, wear, and any other abnormalities.

- Thickness measurement: Use a brake shoe gauge to measure the thickness of the brake shoes and ensure they meet the minimum thickness requirements.

- Coefficient of friction test: Conduct a coefficient of friction test to verify the braking efficiency of the brake shoes.

- Ultrasonic testing: Use ultrasonic equipment to detect any internal defects or cracks that may not be visible during visual inspection.

5. Explain the importance of proper brake valve operation and how to troubleshoot common problems.

Importance of Proper Brake Valve Operation

- Ensures safe and effective braking of the train.

- Maintains the correct air pressure in the brake system.

- Controls the application and release of the brakes.

Troubleshooting Common Problems

- Brake valve stuck in emergency position: Check for air leaks, faulty electrical connections, or mechanical damage.

- Brake valve not releasing: Inspect the release valve, air hoses, and brake cylinders for leaks or obstructions.

- Low brake cylinder pressure: Verify the air compressor is operating correctly, check for leaks in the air lines, and ensure the brake valve is set to the correct position.

6. What are the safety precautions that must be observed when working on railroad brake systems?

Safety precautions to be observed when working on railroad brake systems include:

- Wear appropriate personal protective equipment (PPE).

- De-energize and isolate the brake system before performing any work.

- Bleed off any residual air pressure in the brake system.

- Inspect the brake components for any damage or defects before working on them.

- Follow all established maintenance and repair procedures.

- Never work under a suspended load or put yourself in a position where you could be injured if a component fails.

7. Describe the different types of train brakes and their applications.

Different types of train brakes include:

- Air brakes: Widely used on most railroads, use compressed air to apply and release the brakes.

- Vacuum brakes: Use a vacuum to create a pressure differential that applies the brakes.

- Electro-pneumatic brakes: Combine air brakes with electrical controls for faster and more precise braking.

- Dynamic brakes: Use the traction motors of the locomotive to generate resistance and slow down the train.

- Eddy current brakes: Use magnetic fields to create resistance and slow down the train.

8. What is the purpose of a slack adjuster in a railroad brake system?

A slack adjuster in a railroad brake system serves the following purposes:

- Maintains the correct distance between the brake shoes and the wheels, ensuring proper brake application.

- Compensates for brake shoe wear and thermal expansion, ensuring consistent braking performance.

- Prevents the brake shoes from contacting the wheels when the brakes are not applied, reducing unnecessary wear.

9. Explain the process of troubleshooting and repairing a leaking brake cylinder.

Troubleshooting

- Identify the location of the leak by visually inspecting the brake cylinder and its components.

- Check for loose fittings, damaged seals, or cracks in the cylinder body.

- Isolate the brake cylinder from the air supply and release any residual air pressure.

Repair

- Replace any damaged seals, gaskets, or fittings.

- Reseat the piston and ensure it moves freely within the cylinder.

- Reassemble the brake cylinder and reconnect it to the air supply.

- Test the brake cylinder for leaks and proper operation.

10. Describe the different types of brake rigging used in railroad brake systems.

Different types of brake rigging used in railroad brake systems include:

- Swing hanger brake rigging: A traditional type of rigging where the brake shoes are suspended from a swing hanger attached to the truck frame.

- Unit brake rigging: A more modern type of rigging where the brake shoes are mounted on a single unit that is attached to the truck frame.

- Floating brake rigging: A type of rigging where the brake shoes are free to move laterally, allowing for better brake shoe wear distribution.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Railroad Brake Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Railroad Brake Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Railroad Brake Repairers play a crucial role in ensuring the safe and efficient operation of trains. Their primary responsibilities include:

1. Inspecting and Maintaining Brakes

Regularly inspecting and testing brake systems to identify any malfunctions or defects.

- Performing visual inspections of brake components, including brake shoes, pads, and rotors.

- Using specialized equipment to test brake performance, such as air pressure gauges and brake analyzers.

2. Repairing and Replacing Brake Components

Repairing or replacing brake components as necessary to ensure optimal braking performance.

- Adjusting brake shoes and pads to ensure proper alignment.

- Replacing worn or damaged brake components, such as brake discs, rotors, and calipers.

- Inspecting and repairing brake hoses and lines for leaks or damage.

3. Troubleshooting Brake Systems

Identifying and resolving brake system malfunctions to ensure safe and reliable operation.

- Using diagnostic tools to locate and diagnose brake problems.

- Performing repairs or adjustments to correct brake malfunctions.

- Testing brake systems after repairs to ensure proper functioning.

4. Maintaining Brake-Related Records

Documenting all brake inspections, repairs, and replacements to track maintenance history and ensure compliance.

- Maintaining detailed records of brake system inspections and repairs.

- Completing and submitting inspection reports as required.

- Assisting with the development and implementation of brake system maintenance plans.

Interview Tips

In order to increase your chances of success in an interview, you should prepare in advance. Here are some tips to follow.

intro paragraph

1. Research the Company and the Position

Familiarize yourself with the railroad company’s history, operations, and safety record.

- Visit the company’s website to learn about their values, mission, and recent news.

- Research the specific position you are applying for and identify the key responsibilities and qualifications.

2. Practice Answering Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Practice your answers aloud or with a friend or family member to gain confidence and improve your delivery.

3. Highlight Your Relevant Skills and Experience

Emphasize your technical skills in brake repair, maintenance, and troubleshooting.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Share examples of how you have successfully resolved brake system malfunctions.

4. Be Prepared to Discuss Safety Protocols

Railroad safety is of paramount importance. Demonstrate your understanding of and commitment to safety protocols.

- Explain your experience with railroad safety regulations and best practices.

- Discuss how you ensure the safety of yourself and others while working on brake systems.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position.

- Prepare questions about the company, the position, and the training and development opportunities available.

- Avoid asking questions that are easily answered by researching the company online.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Railroad Brake Repairer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.