Feeling lost in a sea of interview questions? Landed that dream interview for Railroad Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Railroad Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

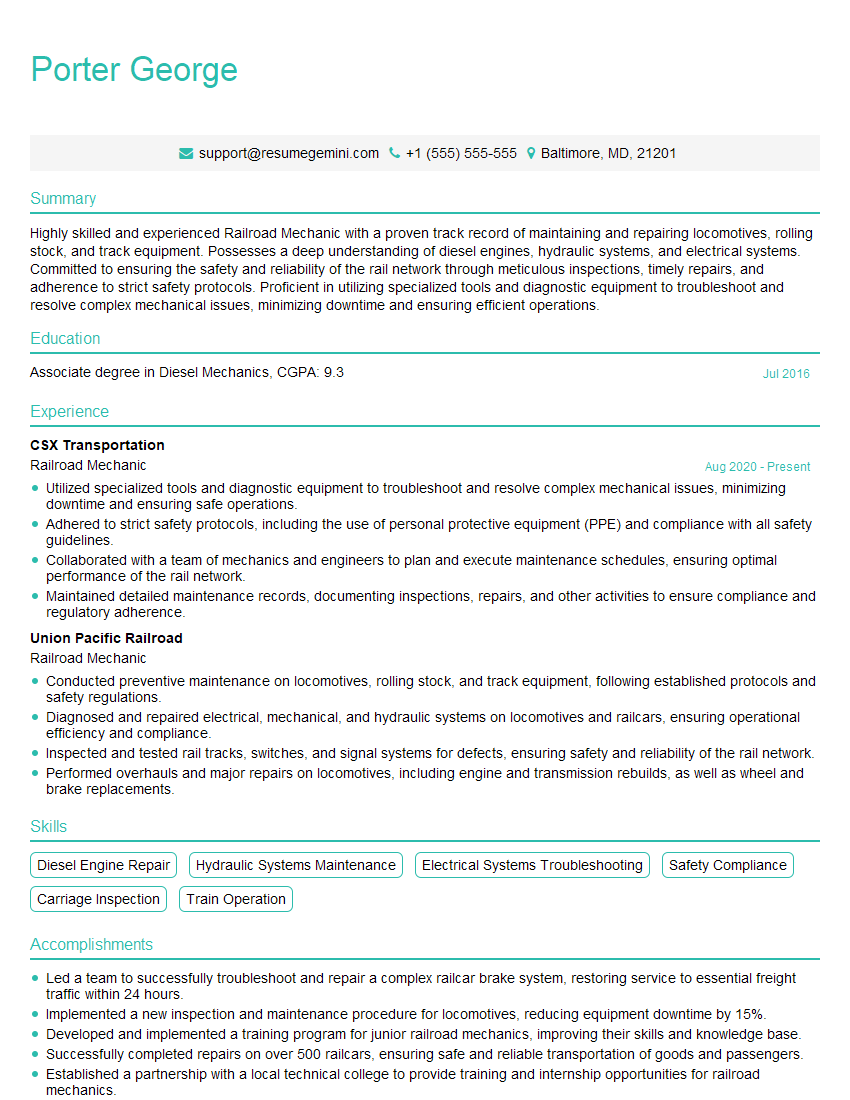

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Railroad Mechanic

1. Describe the process of inspecting a locomotive’s brake system?

- Examine brake pads, shoes, and rotors for wear and damage.

- Check brake fluid levels and condition.

- Inspect brake lines and hoses for leaks or damage.

- Test brake performance using a dynamometer or on-track testing.

- Document inspection findings and make any necessary repairs or adjustments.

2. How do you troubleshoot a locomotive’s electrical system?

Using Diagnostic Equipment

- Connect diagnostic equipment to the locomotive’s electrical system.

- Run tests and analyze data to identify potential faults.

Manual Troubleshooting

- Check wiring for loose connections or damage.

- Inspect electrical components, such as batteries, generators, and relays, for signs of failure.

- Perform continuity and voltage tests to identify specific issues.

3. What are the safety precautions you take when working on railroad equipment?

- Wear appropriate personal protective equipment, including safety glasses, gloves, and hard hat.

- Follow established safety protocols and procedures.

- Use proper tools and equipment for the task.

- Be aware of the potential hazards associated with railroad equipment, such as moving parts and electrical systems.

- Inspect equipment before use and report any defects or concerns.

4. How do you ensure the proper functioning of a locomotive’s engine?

- Regular Maintenance: Perform scheduled inspections, oil changes, and filter replacements.

- Troubleshooting and Repair: Diagnose and repair engine problems using diagnostic equipment and technical knowledge.

- Adjustment and Calibration: Adjust and calibrate engine components, such as fuel injectors and timing, to optimize performance.

- Inspection and Monitoring: Monitor engine parameters, such as temperature, pressure, and vibration, to identify potential issues.

- Recordkeeping: Document all maintenance, repairs, and inspections to track engine performance and identify trends.

5. What is your experience with using specialized railroad tools and equipment?

- Electrical Diagnostic Tools: Multimeters, oscilloscopes, and cable testers.

- Mechanical Repair Equipment: Wrenches, impact drivers, and hydraulic presses.

- Pneumatic and Hydraulic Tools: Air wrenches, impact wrenches, and hydraulic jacks.

- Inspection Tools: Endoscopes, borescopes, and ultrasonic testing equipment.

- Safety Equipment: Fall protection systems, confined space equipment, and arc flash suits.

6. How do you stay up-to-date on the latest railroad industry regulations and best practices?

- Attend industry conferences, seminars, and training programs.

- Review and study relevant regulations and standards, such as the Federal Railroad Administration (FRA) regulations.

- Stay informed through industry publications, newsletters, and online resources.

- Consult with experienced colleagues and mentors.

- Participate in professional organizations and committees related to railroad maintenance.

7. What is your understanding of the principles of railroad dynamics and mechanics?

- Locomotive Dynamics: Tractive force, rolling resistance, and braking forces.

- Train Dynamics: Train handling, braking distances, and curve negotiation.

- Track Mechanics: Track geometry, rail stresses, and wheel-rail interactions.

- Vehicle-Track Interaction: Effects of vehicle weight, speed, and suspension on track performance.

- Vibration and Noise Analysis: Impact of train operations on track and surrounding environment.

8. How do you prioritize and manage multiple tasks effectively in a fast-paced railroad environment?

- Establish Priorities: Determine the most critical tasks based on safety, regulatory compliance, and operational impact.

- Plan and Schedule: Develop a clear work plan and schedule to allocate resources efficiently.

- Delegate Responsibilities: Assign tasks to team members based on their skills and availability.

- Communicate Regularly: Keep team members informed and provide updates on task progress.

- Monitor and Adjust: Regularly review progress and make adjustments to the plan as needed to ensure timely task completion.

9. Describe your experience in working with and managing a team of railroad mechanics.

- Team Leadership: Provided guidance, motivation, and support to team members.

- Skill Development: Identified and provided opportunities for team members to enhance their skills and knowledge.

- Performance Management: Evaluated and provided feedback on team member performance.

- Conflict Resolution: Effectively managed and resolved conflicts within the team.

- Safety Oversight: Ensured compliance with safety regulations and best practices.

10. How do you stay motivated and engaged in a demanding and challenging railroad work environment?

- Sense of Purpose: Understanding the critical role of maintaining railroad safety and efficiency.

- Continuous Learning: Embracing opportunities to expand knowledge and skills.

- Team Collaboration: Working with a dedicated and supportive team.

- Positive Attitude: Maintaining a positive outlook and focusing on solutions.

- Industry Involvement: Participating in industry events and organizations to stay connected and motivated.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Railroad Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Railroad Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Railroad Mechanics are responsible for the maintenance and repair of various rail equipment, including locomotives, freight cars, and track. They work under the supervision of a supervisor or foreman and perform a variety of electrical, mechanical, and plumbing tasks.

1. Diagnose and repair electrical, mechanical, and air brake system issues.

Railroad Mechanics use their knowledge and skills to diagnose and repair a wide variety of issues with rail equipment. This can include electrical problems, such as faulty wiring or malfunctioning components. It can also include mechanical repairs, such as fixing a broken engine or replacing a damaged component.

- Troubleshoot and repair electrical components such as wiring, lighting, and switches.

- Repair and maintain mechanical systems such as engines, transmissions, and brakes.

2. Inspect and repair railcars, locomotives, and other equipment.

Railroad Mechanics are responsible for inspecting and repairing a variety of rail equipment. This includes inspecting the overall condition of the equipment, as well as identifying and repairing any specific issues. They will also work with other departments to ensure that all equipment is safe and reliable.

- Inspect railcars, locomotives, and other equipment for damage or wear.

- Repair or replace damaged or worn components.

- Perform preventive maintenance on equipment to avoid breakdowns.

3. Perform preventive maintenance and repairs.

Railroad Mechanics play a critical role in keeping rail equipment in good condition and preventing breakdowns. They perform preventive maintenance tasks, such as lubrication, cleaning, and inspection. They also perform repairs as needed to ensure that the equipment is safe and reliable.

- Lubricate and clean equipment to prevent wear and tear.

- Inspect equipment for potential problems and make repairs as needed.

- Perform scheduled maintenance on equipment to keep it in good condition.

4. Keep records and documentation.

Railroad Mechanics are responsible for keeping accurate records and documentation of their work. This includes recording the work they have performed, the parts they have used, and any other relevant information. This documentation is important for tracking repairs, identifying trends, and ensuring that the equipment is safe and reliable.

- Keep records of all maintenance and repair work performed.

- Maintain inventory of parts and supplies.

- Prepare reports and documentation for management and regulatory agencies.

Interview Tips

Preparing for an interview is essential to make a good impression and land the job. Here are some tips to help you make the best possible impression.

1. Research the company and position.

It’s important to research the company and the position you’re applying for before the interview. This will help you understand the company’s mission, culture, and values. It will also help you learn more about the role and what the company is looking for in a candidate.

- Visit the company’s website and read about their history, mission, and values.

- Read the job description carefully and note the key qualifications and requirements.

2. Practice answering common interview questions.

One of the best ways to prepare for an interview is to practice answering common interview questions. There are a number of different resources available online and in books that can help you with this. The more you practice, the more confident you will be in your answers.

- Prepare answers to common interview questions, such as:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Practice your answers with a friend or family member.

3. Dress professionally and arrive on time.

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time for your interview. Punctuality shows that you are respectful of the interviewer’s time.

- Wear a suit or business casual attire.

- Arrive for your interview on time.

4. Be yourself and be confident.

It’s important to be yourself and be confident in your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident in your skills and abilities, and let your personality shine through.

- Be genuine and authentic.

- Be confident in your abilities.

- Let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Railroad Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!