Are you gearing up for a career in Rasper Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rasper Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

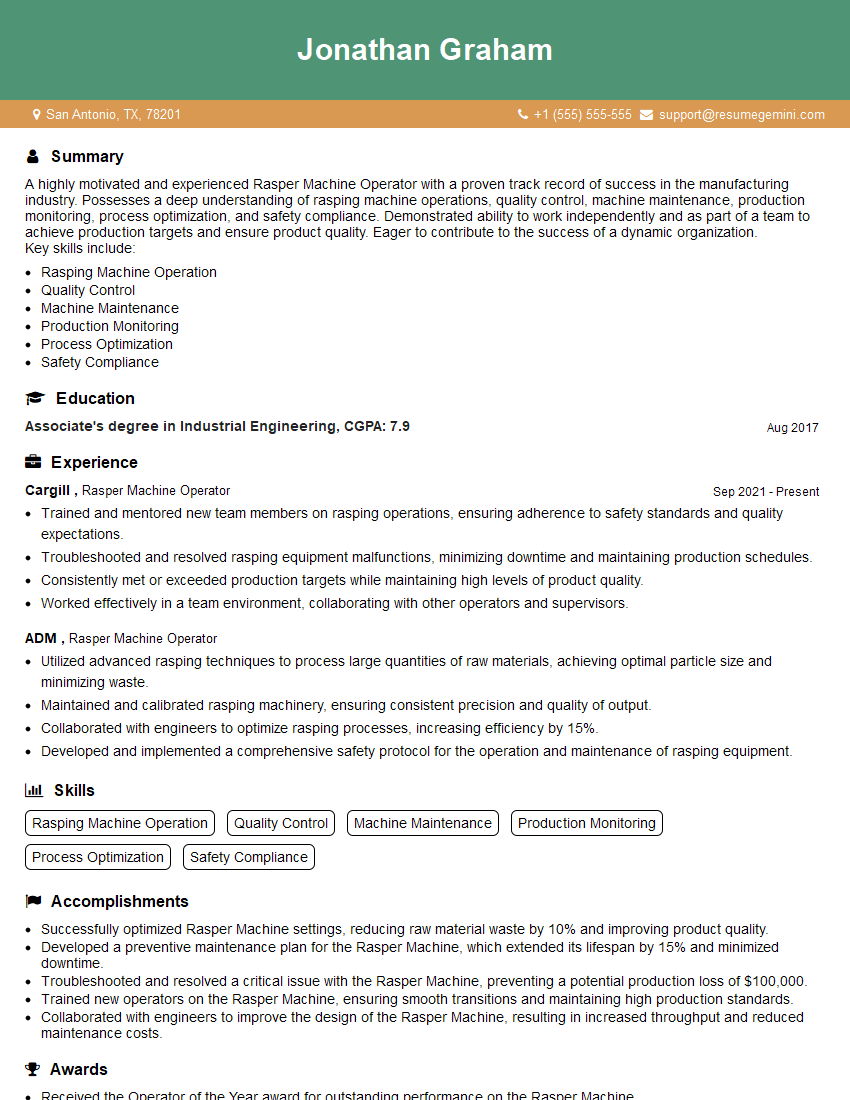

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rasper Machine Operator

1. Explain the process of setting up a Rasper Machine for operation.

- Adjust the machine settings based on the product specifications, including blade speed, feed rate, and material thickness.

- Securely install the blades and ensure they are properly aligned and tensioned.

- Set the conveyor belt speed to match the feed rate of the material.

- Ensure the hopper is filled with raw material and properly adjusted for consistent feeding.

- Calibrate the sensors and safety devices to ensure proper functionality.

2. Describe the different types of materials that can be processed using a Rasper Machine.

Fruit and Vegetables

- Apples

- Carrots

- Celery

Cheese and Dairy Products

- Cheddar

- Mozzarella

- Parmesan

Meat and Poultry

- Chicken

- Beef

- Pork

3. How do you troubleshoot common problems encountered during Rasper Machine operation?

- Uneven rasping: Check blade alignment and tension, adjust feed rate or blade speed.

- Product jams: Clear the hopper and conveyor belt, inspect for foreign objects or material overload.

- Excessive noise or vibration: Check blade balance, tension, or bearings, ensure proper machine alignment.

- Inadequate product quality: Adjust blade sharpness, feed rate, or product specifications, check for blade wear or damage.

- Safety device failures: Inspect sensors, interlocks, and guards regularly, follow maintenance procedures.

4. How do you ensure the safety of yourself and others while operating a Rasper Machine?

- Wear appropriate safety gear, including gloves, safety glasses, and ear protection.

- Follow lockout/tagout procedures before performing maintenance or repairs.

- Maintain a clean and organized work area to prevent slips and falls.

- Keep a safe distance from moving parts and sharp blades.

- Report any unsafe conditions or equipment malfunctions to a supervisor immediately.

5. Describe the maintenance procedures required for a Rasper Machine.

- Regular cleaning of the machine, including blades, hopper, and conveyor belt.

- Blade sharpening or replacement as needed.

- Inspection and adjustment of belts, chains, and bearings.

- Lubrication of moving parts according to manufacturer’s specifications.

- Calibration and testing of safety devices.

6. How do you calculate the production capacity of a Rasper Machine?

- Consider the machine’s rated capacity provided by the manufacturer.

- Estimate the efficiency of the machine based on factors such as material properties, blade sharpness, and operating conditions.

- Determine the desired product thickness and adjust the feed rate accordingly.

- Factor in any downtime for maintenance, cleaning, or product changeovers.

- Use mathematical formulas or consult tables to calculate the theoretical production capacity.

7. What specific quality control measures do you implement to ensure the product meets the desired specifications?

- Regular monitoring of product size, consistency, and appearance.

- Use of gauges or measuring instruments to verify product dimensions.

- Sampling and testing of the product at different stages of the process.

- Calibration and maintenance of inspection equipment.

- Documentation and record-keeping of quality control activities.

8. How do you handle variations in the quality or consistency of the raw material being processed?

- Adjust machine settings, such as feed rate or blade speed, to accommodate variations.

- Sort or grade the raw material to ensure consistent quality.

- Monitor the product quality closely and make adjustments as needed.

- Communicate with suppliers or quality control personnel to identify and mitigate potential issues.

- Implement corrective actions to minimize the impact on product quality.

9. Describe your experience with different types of Rasper Machines.

Rotary Rasper

- Horizontal or vertical orientation

- Rotating drum with fixed blades

Belt Rasper

- Continuous belt with fixed or rotating blades

- Suitable for larger capacities

Disc Rasper

- Rotating disc with fixed or rotating blades

- High-speed operation

10. How do you stay updated on the latest advancements and best practices in Rasper Machine operation?

- Attend industry workshops, conferences, or training programs.

- Read trade publications and technical journals.

- Network with other Rasper Machine operators and professionals.

- Consult with equipment manufacturers and service providers.

- Participate in online forums or discussion groups.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rasper Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rasper Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rasper Machine Operators are responsible for operating and maintaining rasper machines used in the production of wood pulp or other materials. They ensure that the machines are operating safely and efficiently, and that the finished product meets quality standards.

1. Monitor and control the operation of the rasper machine

This includes setting up the machine, loading the material to be processed, and monitoring the progress of the process. The operator must also make adjustments to the machine as needed to ensure that it is operating properly.

2. Inspect the finished product

The operator must inspect the finished product to ensure that it meets quality standards. This may involve checking the product for defects, such as knots or chips, and verifying that the product has the correct size and shape.

3. Clean and maintain the rasper machine

The operator must clean and maintain the rasper machine on a regular basis to ensure that it is operating properly. This may involve cleaning the machine’s parts, lubricating the moving parts, and replacing worn or damaged parts.

4. Troubleshoot and repair the rasper machine

If the rasper machine breaks down, the operator must troubleshoot the problem and repair the machine. This may involve identifying the cause of the problem, replacing damaged parts, or making adjustments to the machine’s settings.

Interview Tips

To prepare for an interview for a Rasper Machine Operator position, candidates should:

1. Research the company and the position

This will help you understand the company’s culture and the specific requirements of the position. You should also review the company’s website and social media pages to get a sense of its values and mission.

2. Practice answering common interview questions

Some common interview questions for Rasper Machine Operator positions include:

- Tell me about your experience operating rasper machines.

- What are the most important safety precautions to take when operating a rasper machine?

- How do you troubleshoot and repair a rasper machine?

- What are your goals for this position?

- Why do you think you are the best person for this position?

3. Dress professionally and arrive on time for your interview

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

4. Be prepared to talk about your experience and skills

The interviewer will likely ask you about your experience operating rasper machines and your skills in troubleshooting and repairing them. Be prepared to talk about your specific experience and how it relates to the requirements of the position.

5. Ask questions about the position and the company

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position to see if it is a good fit for you.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rasper Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!