Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Raw Stock Drier Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

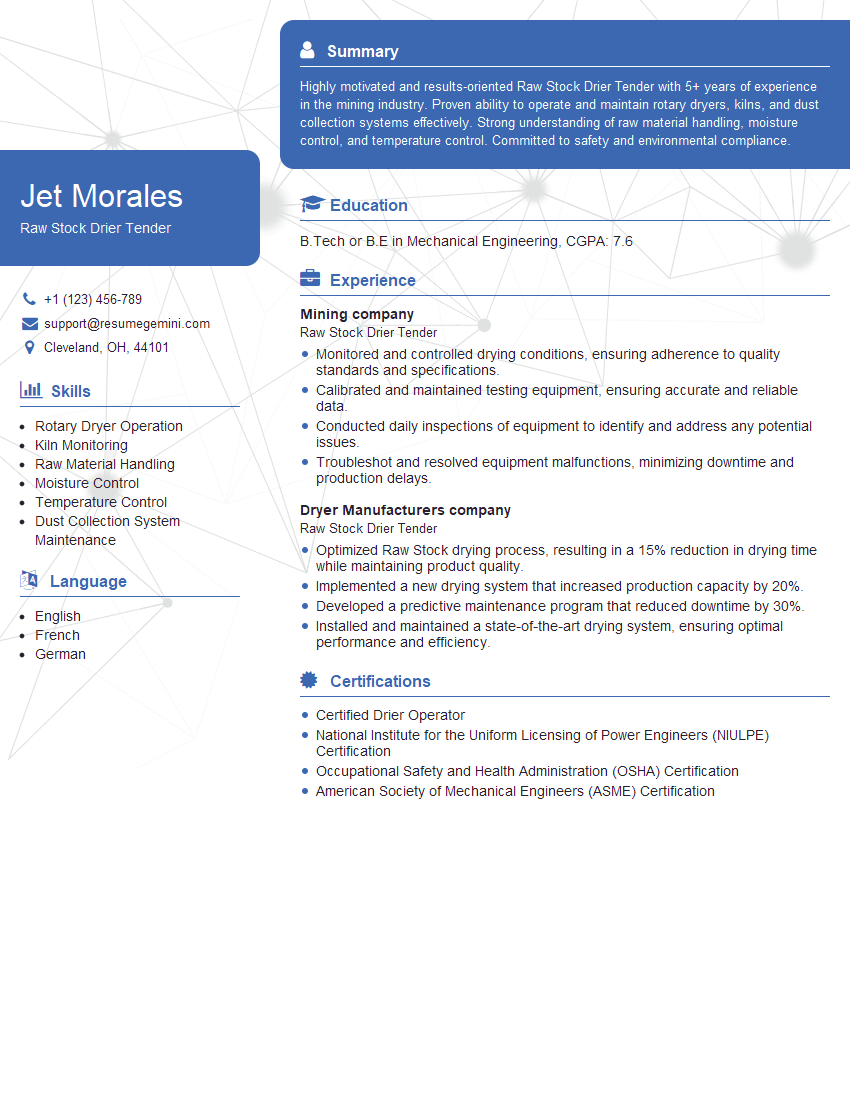

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Raw Stock Drier Tender

1. Describe the process of drying raw stock in a paper mill?

The process of drying raw stock in a paper mill involves several steps:

- Couching: The wet pulp from the paper machine is transferred to a couch roll, which presses out some of the water.

- Pressing: The wet paper sheet is then pressed between a series of rolls to further remove water.

- Drying: The pressed paper sheet is then passed through a series of heated dryers, which evaporate the remaining water and dry the paper.

- Calendering: The dried paper sheet is then passed through a calender stack, which smooths and polishes the surface of the paper.

2. What are the different types of raw stock dryers used in paper mills?

Convection Dryers

- Uses hot air to evaporate moisture from the paper web

- Commonly used in the production of printing and writing papers

Contact Dryers

- Direct contact between the paper web and a heated surface

- Provides high drying rates and is suitable for specialty papers

Steam Heated Dryers

- Uses steam to heat the drying surface

- Energy-efficient and commonly used in the production of packaging papers

3. What are the key parameters to control in the raw stock drying process?

- Drying temperature: The temperature of the drying air or surface.

- Drying time: The amount of time the paper spends in the dryer.

- Moisture content: The desired moisture content of the dried paper.

- Web tension: The tension applied to the paper web during drying.

4. What are the common problems that can occur in the raw stock drying process?

- Web breaks: The paper web can break due to excessive tension or improper drying conditions.

- Cockling: The paper can become wrinkled or curled due to uneven drying.

- Yellowing: The paper can turn yellow due to oxidation or exposure to heat.

- Brittleness: The paper can become brittle due to over-drying.

5. How do you troubleshoot problems in the raw stock drying process?

- Identify the problem: Determine the specific problem that is occurring.

- Check the process parameters: Verify that the drying temperature, time, moisture content, and web tension are within the desired range.

- Inspect the equipment: Check the condition of the dryers, rolls, and other equipment to ensure that they are operating properly.

- Make adjustments: Adjust the process parameters or equipment as necessary to correct the problem.

6. What are the safety precautions to consider when working with raw stock dryers?

- Wear appropriate personal protective equipment (PPE): This includes gloves, safety glasses, and a hard hat.

- Be aware of the moving parts: Keep hands and clothing away from moving parts such as rolls and gears.

- Do not enter the dryer: Never enter the dryer while it is operating.

- Follow lockout/tagout procedures: Lock out and tag out equipment before performing any maintenance or repairs.

7. What are the environmental considerations related to raw stock drying?

- Air emissions: Raw stock drying can release air emissions, such as volatile organic compounds (VOCs) and particulate matter.

- Water usage: The drying process can consume a significant amount of water.

- Energy consumption: Raw stock drying is an energy-intensive process.

8. What are the latest advancements in raw stock drying technology?

- Infrared drying: Uses infrared radiation to heat the paper web, providing more efficient and uniform drying.

- Microwave drying: Uses microwave energy to heat the paper web, reducing drying time and energy consumption.

- Closed-loop drying: Recirculates and reuses the hot air from the dryer, reducing energy consumption and emissions.

9. How do you stay up-to-date on the latest developments in raw stock drying technology?

- Attend industry conferences and exhibitions: Network with peers and learn about new technologies.

- Read technical journals and publications: Stay informed about the latest research and advancements.

- Participate in professional organizations: Join organizations like TAPPI (Technical Association of the Pulp and Paper Industry) for access to technical resources and networking opportunities.

10. How do you ensure that the raw stock drying process is running efficiently and producing high-quality paper?

- Monitor process parameters: Continuously monitor and adjust drying temperature, time, moisture content, and web tension to optimize drying efficiency.

- Regular maintenance: Perform regular maintenance on dryers, rolls, and other equipment to prevent breakdowns and ensure optimal performance.

- Quality control: Implement quality control measures to ensure that the dried paper meets the desired specifications.

- Employee training: Train operators on proper drying techniques and safety procedures to minimize errors and improve productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Raw Stock Drier Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Raw Stock Drier Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Raw Stock Drier Tenders play a crucial role in textile manufacturing by operating and maintaining raw stock driers, ensuring the efficient drying of raw materials.

1. Dryer Operation and Maintenance

Operate raw stock driers according to established procedures.

- Monitor dryer performance, including temperature, humidity, and airflow.

- Perform routine maintenance and cleaning tasks to ensure optimal dryer functioning.

2. Raw Stock Handling

Load and unload raw stock into and out of the drier.

- Inspect raw stock for quality and consistency.

- Control the moisture content of the dried stock to meet specifications.

3. Process Monitoring

Monitor the drying process to ensure the desired moisture level and quality of the dried stock.

- Conduct regular quality checks and make adjustments as needed.

- Identify any process deviations or equipment malfunctions and report them promptly.

4. Safety and Compliance

Follow all safety protocols and regulations related to dryer operation.

- Wear appropriate personal protective equipment (PPE).

- Maintain a clean and organized work area to prevent accidents.

Interview Tips

Preparing for a Raw Stock Drier Tender interview requires a combination of technical knowledge and a strong understanding of the industry. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Learn about the company’s history, products, and manufacturing processes.

- Research the raw stock drying industry to understand current trends and best practices.

- Read industry publications and articles to stay informed about advancements in drying technology.

2. Highlight Your Technical Skills

Emphasize your experience in operating and maintaining raw stock driers.

- Provide specific examples of how you have optimized dryer performance and resolved equipment issues.

- Discuss your understanding of different dryer types and drying processes.

3. Demonstrate Your Process Knowledge

Explain your understanding of the importance of controlling moisture content in raw stock drying.

- Describe the factors that can impact the drying process and how you would adjust accordingly.

- Share your experience in conducting quality checks and identifying process deviations.

4. Emphasize Safety and Compliance

Stress your commitment to safety and adherence to all regulations.

- Provide examples of how you have ensured a safe work environment in previous roles.

- Explain how you stay updated on the latest safety protocols and comply with industry standards.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Raw Stock Drier Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!