Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Re Etcher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

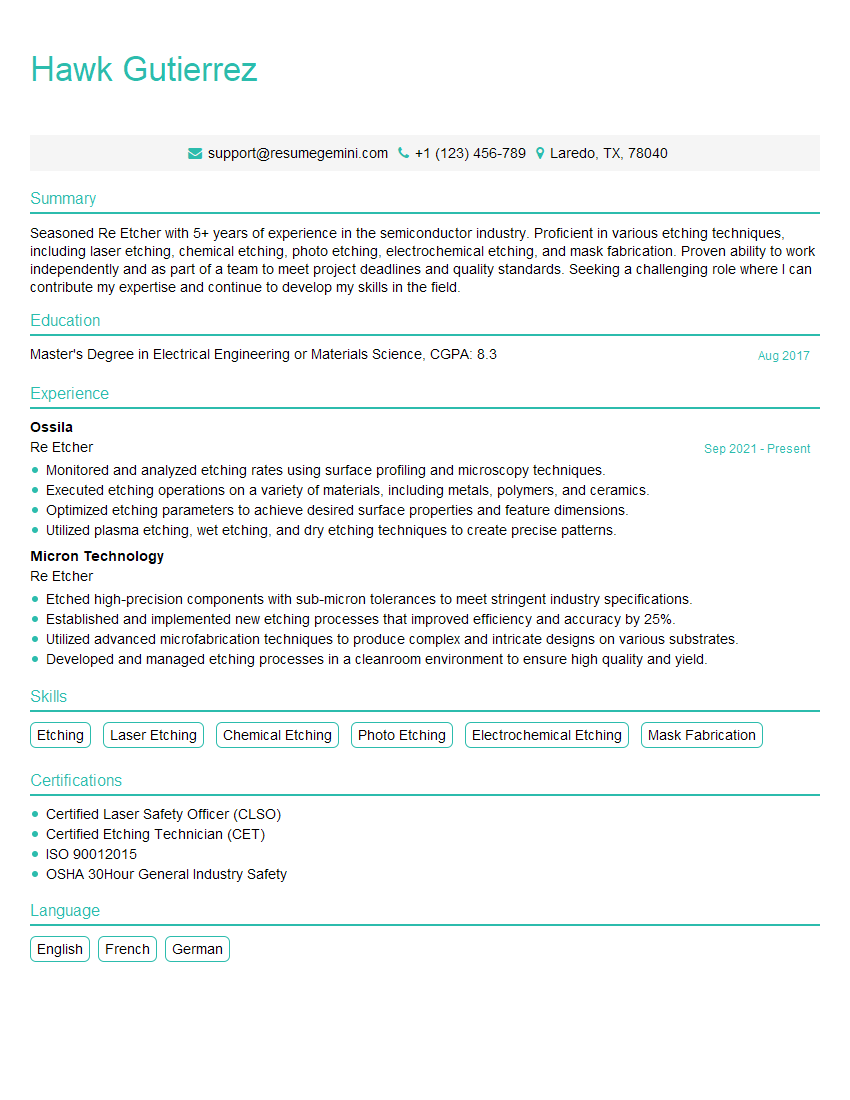

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Re Etcher

1. What is the process of etching and how does it differ from engraving?

Etching is a process of creating a design on metal by using a chemical solution to dissolve the metal. Engraving, on the other hand, is a process of creating a design on metal by using a sharp tool to cut into the metal. Etching is typically used to create intricate designs, while engraving is typically used to create bolder, more defined designs.

2. What are the different types of etching techniques?

There are many different types of etching techniques, including:

- Photoetching

- Chemical etching

- Electrochemical etching

- Laser etching

3. What are the advantages and disadvantages of using different types of etching techniques?

The advantages and disadvantages of using different types of etching techniques vary depending on the specific technique being used. Some of the general advantages of etching include:

- High precision

- Intricate designs

- Relatively low cost

Some of the disadvantages of etching include:

- Can be time-consuming

- Can be difficult to control the depth of the etch

- Can produce hazardous waste

4. What are the different applications of etching?

Etching is used in a wide variety of applications, including:

- Creating printed circuit boards

- Decorating jewelry

- Creating metal sculptures

- Manufacturing medical devices

5. What are the safety precautions that should be taken when etching?

When etching, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and a lab coat.

- Work in a well-ventilated area.

- Handle chemicals carefully and dispose of them properly.

- Be aware of the potential fire and explosion hazards associated with etching.

6. What are the challenges of etching?

Some of the challenges of etching include:

- Controlling the depth of the etch

- Creating intricate designs

- Avoiding undercutting

- Dealing with hazardous waste

7. What are the trends in etching technology?

Some of the trends in etching technology include:

- The development of new etching techniques, such as laser etching and electrochemical etching

- The use of new materials, such as graphene and other 2D materials

- The development of new applications for etching, such as in the field of nanotechnology

8. What are the future prospects for etching?

The future prospects for etching are bright. Etching is a versatile and powerful technology that is used in a wide variety of applications. As new etching techniques and materials are developed, the use of etching is expected to continue to grow in the future.

9. What are the different types of etching machines?

There are many different types of etching machines, each with its own advantages and disadvantages. Some of the most common types of etching machines include:

- Wet etching machines

- Dry etching machines

- Plasma etching machines

- Laser etching machines

10. What are the factors to consider when choosing an etching machine?

When choosing an etching machine, there are a number of factors to consider, including:

- The type of material to be etched

- The desired etch depth

- The desired etch rate

- The desired etch quality

- The budget

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Re Etcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Re Etcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Re Etcher is responsible for removing excess photoresist from a semiconductor wafer after the photolithography process. Their key responsibilities include:

1. Removing Photoresist

Using wet or dry etching techniques, Re Etchers remove the photoresist from the wafer, exposing the underlying semiconductor material.

- Wet etching involves immersing the wafer in a chemical solution that dissolves the photoresist.

- Dry etching uses a plasma or reactive gas to etch away the photoresist.

2. Controlling Etch Rate

Re Etchers must carefully control the etch rate to ensure that the desired pattern is achieved without damaging the underlying semiconductor material.

- They use various process parameters, such as temperature, pressure, and chemical concentration, to control the etch rate.

- Monitoring the etch process closely to ensure that it is proceeding as planned.

3. Maintaining Equipment

Re Etchers are responsible for maintaining and calibrating the etching equipment they use.

- They perform regular maintenance checks and troubleshoot any problems that may arise.

- Keeping detailed records of the equipment’s performance and any repairs or maintenance performed.

4. Quality Control

Re Etchers are responsible for ensuring that the etched wafers meet the required specifications.

- They inspect the wafers for defects using optical and electrical testing methods.

- Analyzing the results of the tests to identify any areas where the process needs to be improved.

Interview Tips

To ace an interview for a Re Etcher position, it is important to prepare thoroughly and demonstrate your knowledge and skills. Here are some tips:

1. Research the Company and the Role

Before the interview, take the time to research the company and the specific Re Etcher position you are applying for. This will help you understand the company’s culture, values, and the specific requirements of the role.

- Visit the company’s website to learn about their products, services, and mission.

- Read industry publications and news articles to stay up-to-date on the latest trends and technologies in the field.

2. Prepare for Technical Questions

Be prepared to answer technical questions about the Re Etcher process, equipment, and quality control procedures. Practice answering questions about:

- The different types of etching techniques and their advantages and disadvantages.

- The factors that affect the etch rate and how to control it.

- The methods used to maintain and calibrate etching equipment.

- The quality control procedures used to ensure that etched wafers meet specifications.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Re Etcher position. Focus on your:

- Knowledge of etching processes and equipment.

- Experience in maintaining and calibrating etching equipment.

- Ability to troubleshoot problems and resolve issues.

- Attention to detail and commitment to quality.

4. Ask Informed Questions

At the end of the interview, be sure to ask informed questions about the company, the role, and the team you would be working with. This shows that you are engaged and interested in the position.

- Ask about the company’s plans for the future and how the Re Etcher role fits into those plans.

- Ask about the team you would be working with and the company’s culture.

- Ask about the opportunities for professional development and growth within the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Re Etcher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Re Etcher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.